sewing locking machine

The Importance of Sewing Locking Machines in Modern Textile Production

In the world of textile production, sewing locking machines play an indispensable role. These machines are crucial for sewing seams that require a strong and durable finish, particularly in garments and various fabric products. As the demand for high-quality textiles continues to rise, understanding the functionalities and benefits of sewing locking machines is essential for manufacturers and hobbyists alike.

Understanding Sewing Locking Machines

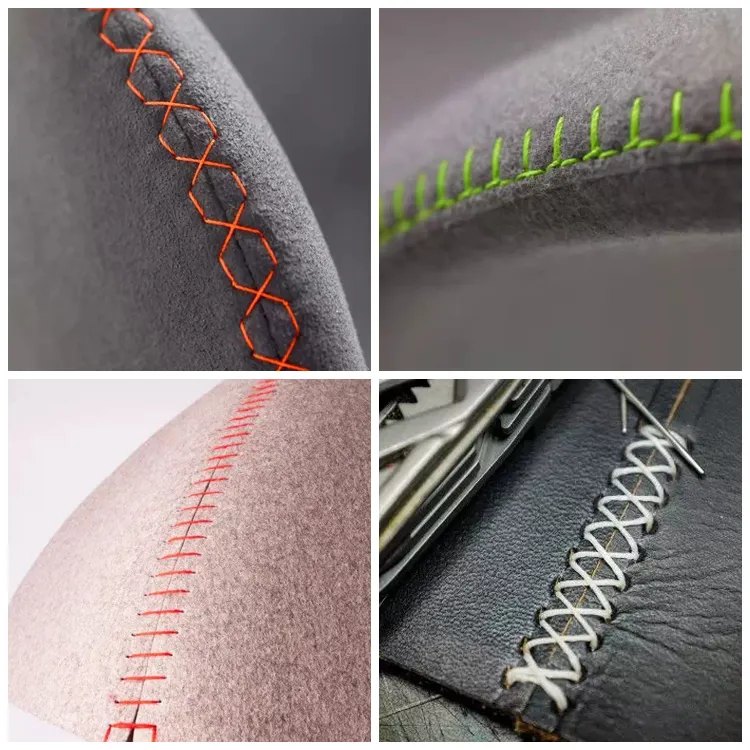

Sewing locking machines are designed to create stitches that interlock threads, offering superior strength compared to basic sewing machines. The most common types of locking machines are overlock machines, flatlock machines, and coverstitch machines. Each of these serves distinct purposes but shares the common goal of enhancing seam strength and appearance.

Overlock Machines These are designed for edge finishing and preventing fabric from fraying. They trim the fabric edges while sewing, providing a clean, polished look. Overlock machines are often utilized in knitwear and stretch fabrics, making them ideal for garments like t-shirts and leggings.

Flatlock Machines As the name suggests, flatlock machines produce flat seams that lie flush against the fabric. This type of seam is commonly used in athletic wear, where comfort and flexibility are paramount. Flatlock seams are also aesthetically pleasing, providing a neat finish that can be showcased rather than hidden.

Coverstitch Machines These machines are often used to sew hems and finish seams simultaneously. They offer a combination of a straight and a chain stitch, which adds elasticity to the seams, making them perfect for garments that require a good degree of stretch.

Benefits of Using Sewing Locking Machines

1. Durability One of the primary advantages of sewing locking machines is the durability of the stitches they create. Locking machines interlock threads in a way that compromises the seam's integrity, which is especially important for garments subject to stress and movement.

sewing locking machine

2. Versatility Sewing locking machines can handle various fabric types and thicknesses, making them an essential tool for fabricators working with diverse materials, from lightweight cotton to heavy denim and stretch fabrics.

3. Professional Finish These machines provide a neat and professional finish to seams, which is vital for commercial production. The ability to create clean, flat seams enhances the overall quality of the garment, which can improve competitiveness in the market.

4. Increased Efficiency Locking machines are designed for speed and efficiency, allowing for quicker production times without sacrificing quality. This efficiency is critical in a commercial setting where meeting deadlines is paramount.

5. Ease of Use Modern locking machines come equipped with user-friendly features such as automated threading systems, adjustable stitch lengths, and presser foot pressure settings. These functionalities make it easier for both novice and experienced sewers to achieve professional results.

The Impact of Technological Advancements

As technology continues to evolve, sewing locking machines have benefited from numerous innovations. Today’s machines are often equipped with computerized systems that allow for precise stitch selection and customization. Some advanced models even feature programmable settings that cater to specific fabric types and sewing requirements, making them more adaptable and user-friendly.

Additionally, with the rise of sustainability in fashion, many manufacturers are turning to locking machines that optimize fabric usage, reducing waste and improving production efficiency. This shift not only meets market demands but also aligns with growing environmental consciousness among consumers.

Conclusion

Sewing locking machines are a cornerstone of modern textile manufacturing. Their ability to create durable, versatile, and professional-quality seams makes them an essential tool for anyone involved in fabric production, from large-scale manufacturers to independent designers and hobbyists. As technology advances, these machines will likely become even more integral to the industry, enabling greater efficiency and sustainability in textile production. Understanding and utilizing sewing locking machines effectively can significantly impact the quality and success of textile products in an increasingly competitive market. Whether for commercial use or personal projects, investing in a good-quality locking machine can elevate the sewing experience and outcomes dramatically.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025