Feb . 18, 2025 06:20

Back to list

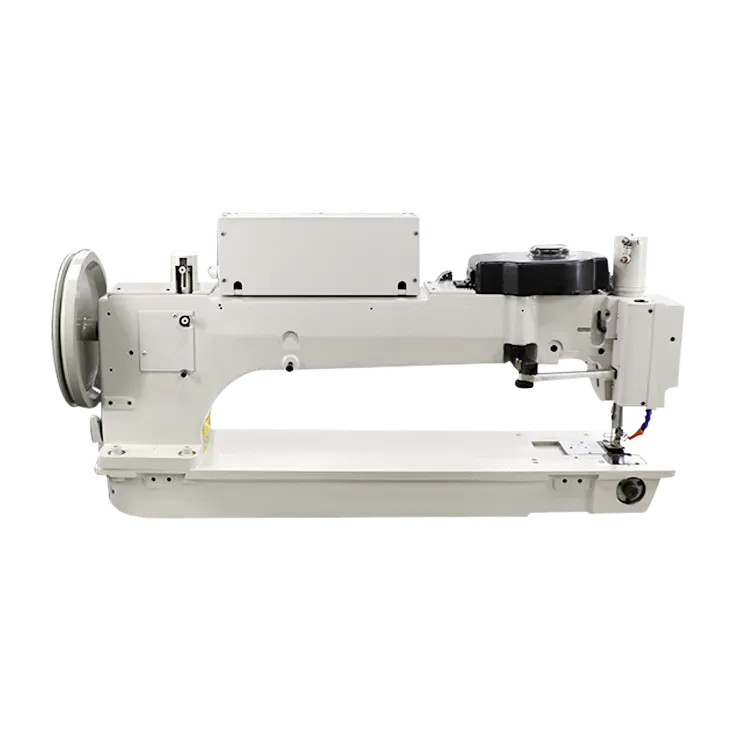

sail making sewing machine

In the realm of crafting superior sails, the sail making sewing machine stands as a pinnacle of engineering excellence and craftsmanship. When delving into the intricacies of sail making, the importance of an expertly calibrated sewing machine becomes immediately apparent. Not only does it streamline the manufacturing process, but it also ensures precision and durability — key attributes for any sail under the duress of wind and weather.

In practice, leveraging a sail making sewing machine involves an understanding of both the machine and the materials in use. Applying this expertise can significantly reduce production time while enhancing the quality of the final product. There is a nuanced technique in handling different fabric types under the presser foot, necessitating adjustments to stitch length and width depending on material elasticity and intended sail function, be it for cruising or racing. For those entrenched in the world of sail fabrications, engaging with a sail making sewing machine is not merely about assembly; it’s about understanding the symbiotic relationship between machinery and material. As sails are integral to a vessel's performance out at sea, ensuring their durability and precision through meticulous craftsmanship is paramount. Hence, the role of the sail making sewing machine extends beyond simple fabrication; it is an instrument of craftsmanship that demands both respect and understanding. The journey from fabric to a fully functional sail requires not only the right tools but also the right expertise. Keeping abreast of technological developments in sewing machinery ensures competitive advantage and allows for innovations in sail design. Thus, investing in a quality sail making sewing machine is also an investment in elevating one's craft. In conclusion, the sail making sewing machine is a critical component in the creation of high-performing sails. As technology advances and the demands of sailors evolve, so too must the tools used to construct these maritime essentials. Combining experience with cutting-edge equipment allows sailmakers to produce sails that not only meet but exceed expectations, ensuring that when vessels take on the sea, they do so with unmatched grace and agility.

In practice, leveraging a sail making sewing machine involves an understanding of both the machine and the materials in use. Applying this expertise can significantly reduce production time while enhancing the quality of the final product. There is a nuanced technique in handling different fabric types under the presser foot, necessitating adjustments to stitch length and width depending on material elasticity and intended sail function, be it for cruising or racing. For those entrenched in the world of sail fabrications, engaging with a sail making sewing machine is not merely about assembly; it’s about understanding the symbiotic relationship between machinery and material. As sails are integral to a vessel's performance out at sea, ensuring their durability and precision through meticulous craftsmanship is paramount. Hence, the role of the sail making sewing machine extends beyond simple fabrication; it is an instrument of craftsmanship that demands both respect and understanding. The journey from fabric to a fully functional sail requires not only the right tools but also the right expertise. Keeping abreast of technological developments in sewing machinery ensures competitive advantage and allows for innovations in sail design. Thus, investing in a quality sail making sewing machine is also an investment in elevating one's craft. In conclusion, the sail making sewing machine is a critical component in the creation of high-performing sails. As technology advances and the demands of sailors evolve, so too must the tools used to construct these maritime essentials. Combining experience with cutting-edge equipment allows sailmakers to produce sails that not only meet but exceed expectations, ensuring that when vessels take on the sea, they do so with unmatched grace and agility.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025