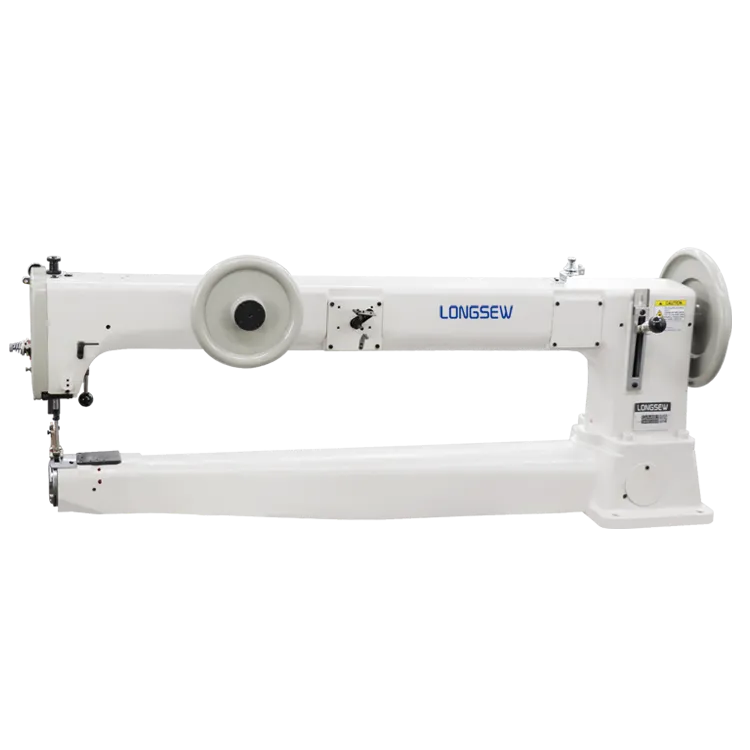

sail making machine

The Evolution and Importance of Sail Making Machines

Sail making has been an essential craft for thousands of years, playing a crucial role in maritime trade, navigation, and exploration. As the world progressed through the ages, so did the technologies associated with sail making. Among these advancements, sail making machines have emerged as pivotal tools in the industry, significantly improving efficiency, accuracy, and quality in sail production.

Historically, sails were made entirely by hand, requiring immense skill, time, and labor. Craftsmen would meticulously cut, sew, and assemble sails using traditional methods, often in small workshops or at shipyards. The process was labor-intensive and limited by the artisan's speed and skill, leading to varying quality and significant time delays. However, as sailing vessels became larger and the demand for sails increased with the growth of trade and exploration, the need for efficient production methods became evident.

The advent of the Industrial Revolution marked a turning point for sail making. The introduction of mechanized equipment transformed many manual processes into automated tasks, allowing for the mass production of sails. Early sail making machines were relatively simple. They included innovations such as sewing machines specifically designed for heavy, durable fabrics used in sail production. These machines could stitch multiple layers of material rapidly and uniformly, drastically reducing the amount of time required to create sails.

As technology progressed, more sophisticated sail making machines were developed

. Modern sail making facilities now utilize advanced computerized cutting machines that can precisely cut sail panels from large rolls of fabric based on digital designs. These machines rely on software that can optimize material use, reducing waste and ensuring that each piece fits perfectly with others. The integration of Computer-Aided Design (CAD) technology has revolutionized how sails are designed and manufactured, allowing for intricate designs and custom shapes to be produced with ease.sail making machine

In addition to cutting and sewing, modern sail making machines can also incorporate features such as automated panel layout, reinforcing stitching, and hemming. This has enabled sail manufacturers to produce sails that are not only stronger and more durable but also tailored to the specific needs of different types of vessels, from small sailboats to large yachts and commercial ships.

The benefits of these machines extend beyond just the manufacturing process. By standardizing quality and reducing production times, sail making machines have greatly contributed to the accessibility of sailing. More people can now afford high-quality sails, promoting recreational sailing and maritime activities on a broader scale. Furthermore, this efficiency has opened up avenues for innovation in sail materials and designs, pushing the boundaries of what is possible in terms of performance and durability.

Moreover, the sustainability aspect cannot be overlooked. With the rise of eco-friendly materials, many modern sail makers are integrating sustainable practices into their production processes. Sail making machines equipped with precise cutting and sewing capabilities are helping to minimize fabric waste, enhancing sustainable production methods in the marine industry.

In conclusion, sail making machines represent a significant advancement in the art and craft of sail production. They have revolutionized the industry by improving efficiency, ensuring quality, and enhancing creativity in sail design. As technology continues to evolve, it is exciting to anticipate what the future holds for sail making and how innovations will further shape this timeless maritime tradition. Whether for competitive racing or leisurely cruising, the impact of sail making machines is felt across the globe, helping to bring the thrill of sailing to more enthusiasts than ever before.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025