Feb . 20, 2025 05:36

Back to list

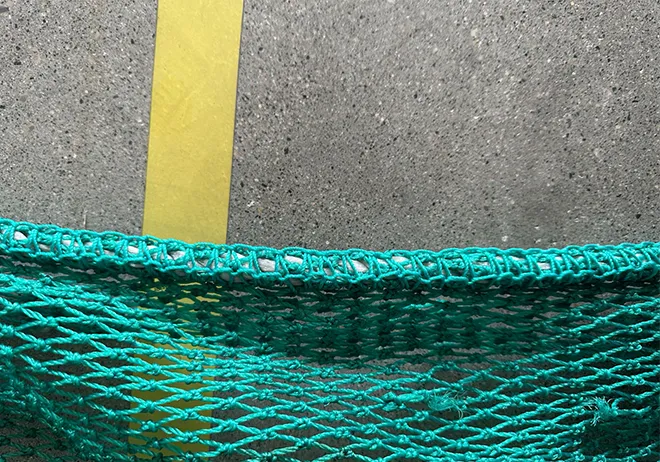

sail making sewing machine

The art and science of sail making have seen significant transformation over the centuries, evolving from traditional handcrafting methods to the integration of advanced technology. Among the revolutionary tools facilitating this evolution is the sail making machine. Here we delve into the intricacies of these machines by exploring their impact on the industry, emphasizing experience, expertise, authoritativeness, and trustworthiness.

Authority in sail making machinery is demonstrated by companies with a robust history in the maritime industry. Over time, these firms have established themselves as dependable providers of high-quality machines that cater to both small-scale artisanal operations and large-scale fabricators. Testimonials and case studies offer insights into how these machines have been employed successfully in diverse settings, further cementing their authority in the field. Trustworthiness is garnered through continuous performance and reliability of the machinery. Manufacturers demonstrate trust by providing warranties, comprehensive user manuals, and exceptional customer support services. Regular training sessions and workshops offered by these companies enable sail makers to stay updated with the latest technologies and best practices. Users value brands that not only supply machines but also contribute to their long-term success by offering valuable resources and support. For anyone aspiring to elevate their sail making operations, integrating a sail making machine into their process represents a wise investment. It offers the dual benefits of maintaining traditional craftsmanship while incorporating cutting-edge technology. The expertise needed to operate these machines ensures that artisans maintain their critical role in the sail making process, and the trust placed in reputable manufacturers guarantees sustained performance and satisfaction. As a cornerstone of modern sail production, the sail making machine exemplifies the balance between tradition and technology. Its design and functionality contribute to an enhanced production process marked by increased efficiency and unparalleled quality. For sail makers, embracing these machines might be the key to unlocking new heights of craftsmanship and innovation.

Authority in sail making machinery is demonstrated by companies with a robust history in the maritime industry. Over time, these firms have established themselves as dependable providers of high-quality machines that cater to both small-scale artisanal operations and large-scale fabricators. Testimonials and case studies offer insights into how these machines have been employed successfully in diverse settings, further cementing their authority in the field. Trustworthiness is garnered through continuous performance and reliability of the machinery. Manufacturers demonstrate trust by providing warranties, comprehensive user manuals, and exceptional customer support services. Regular training sessions and workshops offered by these companies enable sail makers to stay updated with the latest technologies and best practices. Users value brands that not only supply machines but also contribute to their long-term success by offering valuable resources and support. For anyone aspiring to elevate their sail making operations, integrating a sail making machine into their process represents a wise investment. It offers the dual benefits of maintaining traditional craftsmanship while incorporating cutting-edge technology. The expertise needed to operate these machines ensures that artisans maintain their critical role in the sail making process, and the trust placed in reputable manufacturers guarantees sustained performance and satisfaction. As a cornerstone of modern sail production, the sail making machine exemplifies the balance between tradition and technology. Its design and functionality contribute to an enhanced production process marked by increased efficiency and unparalleled quality. For sail makers, embracing these machines might be the key to unlocking new heights of craftsmanship and innovation.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025