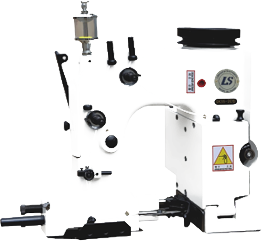

Safety Sewing Machine for Durable Rope and High-Quality Stitching Performance

The Importance of Safety Rope Sewing Machines in Industrial Applications

In various industrial sectors, the demand for robust and reliable safety equipment is paramount. Among these essential tools are safety ropes, which are critical for ensuring the safety of workers in high-risk environments such as construction sites, manufacturing plants, and rescue operations. To create these safety ropes, specialized equipment known as safety rope sewing machines plays a vital role.

Safety rope sewing machines are designed to handle heavy-duty materials that are both strong and resilient. These machines are capable of stitching together different types of ropes, including those made from synthetic fibers like polypropylene, nylon, and polyester. The unique requirements of safety rope manufacturing necessitate precision and durability, characteristics that only advanced sewing machines can provide.

One of the primary benefits of using safety rope sewing machines is the ability to produce high-quality, customized ropes tailored to specific safety standards. For instance, the machines can create ropes that adhere to national safety regulations, ensuring that they can withstand the extreme conditions and loads they may encounter in the field. The stitching patterns and techniques employed in these machines are designed to enhance the strength and resistance of the ropes, making them reliable for use in various applications.

safety rope sewing machine

Moreover, safety rope sewing machines significantly improve production efficiency. With the ability to automate the sewing process, manufacturers can reduce labor costs and production time while maintaining consistent quality. High-speed sewing machines equipped with advanced technology can produce a large volume of ropes in a shorter time, allowing businesses to meet increasing demand without compromising on safety or quality.

In addition to efficiency, these machines also emphasize operator safety. Many modern safety rope sewing machines are equipped with features that minimize the risk of accidents during operation. Safety guards, automatic shut-off features, and user-friendly controls ensure a safer working environment for operators, which aligns with the industry's overarching goal of promoting safety.

The integration of technology in safety rope sewing machines has also led to innovations such as computerized systems that allow for precise monitoring and adjustments during the sewing process. These advancements not only enhance the quality of the end product but also provide valuable data that can be used for future improvements and quality control.

In conclusion, safety rope sewing machines are an indispensable asset in the production of safety ropes. Their ability to produce high-quality, durable, and customized ropes ensures that workers in hazardous environments are protected. As technology continues to evolve, these machines will play an increasingly crucial role in enhancing workplace safety standards and responding to the growing demands of various industries.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025