Feb . 14, 2025 09:34

Back to list

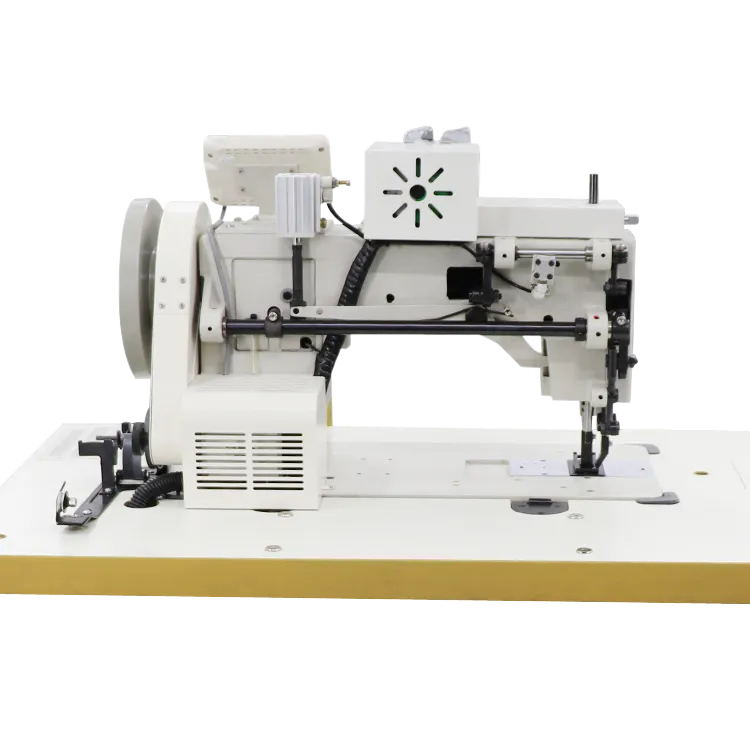

saddle sewing machine

Saddle sewing machines are a vital component in the arsenal of any leatherworker or large-scale manufacturer focusing on heavy-duty materials. These machines are designed to stitch thick pieces of leather or multi-layer fabrics with precision and durability, making them indispensable for producing high-quality saddles, harnesses, bags, and other leather goods. The evolution of these machines has been remarkable, offering features and innovations that cater to both artisanal craftsmanship and industrial production efficiency.

When integrating a new saddle sewing machine into an existing line of equipment, it is important to undertake a comprehensive training program. Knowledge of safety protocols and machine maintenance forms the backbone of any operation involving heavy-duty sewing machines. Such training not only mitigates risks associated with machine operation but also extends the life of the equipment by ensuring it is used in compliance with the manufacturer's guidelines. In terms of experience, owner testimonials and case studies often serve as invaluable resources for prospective buyers aiming to find the perfect match for their needs. Real-world scenarios illustrate how specific models of saddle sewing machines perform under various conditions and materials, providing realistic expectations and insights. Thus, engaging with communities—both online forums and industry conferences—is essential for gathering experiential knowledge that can influence purchasing decisions. Finally, sustainability is becoming an increasingly important consideration for many modern manufacturers. While traditional saddle sewing has always been aligned with the use of natural materials like leather, the push towards environmentally conscious production methods influences the type of machinery used. Machines that incorporate energy-efficient motors and minimal waste processes appeal to businesses looking to reduce their carbon footprint, thereby aligning with broader corporate social responsibility goals. Overall, the saddle sewing machine remains an indispensable tool in the realm of leatherworking, bridging the gap between traditional craftsmanship and modern manufacturing technologies. With advancements in technology and increasing demands for both high-quality products and sustainable practices, these machines will continue to evolve, meeting the needs of artisans and industrial titans alike. Investing in a reliable, efficient, and expertly crafted saddle sewing machine can elevate any production process, ensuring that each stitch stands the test of time.

When integrating a new saddle sewing machine into an existing line of equipment, it is important to undertake a comprehensive training program. Knowledge of safety protocols and machine maintenance forms the backbone of any operation involving heavy-duty sewing machines. Such training not only mitigates risks associated with machine operation but also extends the life of the equipment by ensuring it is used in compliance with the manufacturer's guidelines. In terms of experience, owner testimonials and case studies often serve as invaluable resources for prospective buyers aiming to find the perfect match for their needs. Real-world scenarios illustrate how specific models of saddle sewing machines perform under various conditions and materials, providing realistic expectations and insights. Thus, engaging with communities—both online forums and industry conferences—is essential for gathering experiential knowledge that can influence purchasing decisions. Finally, sustainability is becoming an increasingly important consideration for many modern manufacturers. While traditional saddle sewing has always been aligned with the use of natural materials like leather, the push towards environmentally conscious production methods influences the type of machinery used. Machines that incorporate energy-efficient motors and minimal waste processes appeal to businesses looking to reduce their carbon footprint, thereby aligning with broader corporate social responsibility goals. Overall, the saddle sewing machine remains an indispensable tool in the realm of leatherworking, bridging the gap between traditional craftsmanship and modern manufacturing technologies. With advancements in technology and increasing demands for both high-quality products and sustainable practices, these machines will continue to evolve, meeting the needs of artisans and industrial titans alike. Investing in a reliable, efficient, and expertly crafted saddle sewing machine can elevate any production process, ensuring that each stitch stands the test of time.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025