saddle sewing machine

The Saddle Sewing Machine A Cornerstone of Leather Crafting

The saddle sewing machine stands as a testament to the evolution of leather crafting technology, particularly in the realm of saddlery and leather goods manufacturing. Designed specifically for stitching heavy materials like leather and canvas, these machines have transformed the way artisans, companies, and even hobbyists create complex leather items, ranging from horse saddles to bags, belts, and more.

Historical Background

The journey of the saddle sewing machine began in the 19th century, when the need for durable and precise stitching on leather goods was increasingly recognized. Before mechanization, artisans relied on hand stitching, which, while fulfilling, was time-consuming and often inconsistent. The introduction of sewing machines marked a revolutionary shift in this trade, enabling craftspeople to enhance their productivity without compromising on quality.

The early models of saddle sewing machines were largely influenced by the designs of general sewing machines but were adapted to handle the thicker materials and denser threads used in leatherworking. Innovations in needle design, feed mechanisms, and stitch types were necessary to accommodate the unique properties of leather. As a result, the saddle sewing machine became an indispensable tool for saddlers and leatherworkers alike.

Features of Saddle Sewing Machines

Modern saddle sewing machines come equipped with various features tailored to the needs of leather crafting. A robust motor provides the strength required to stitch through multiple layers of leather, while a walking foot mechanism ensures even feeding of the material. This is critical when working with thick pieces of leather, preventing slipping and misalignment.

saddle sewing machine

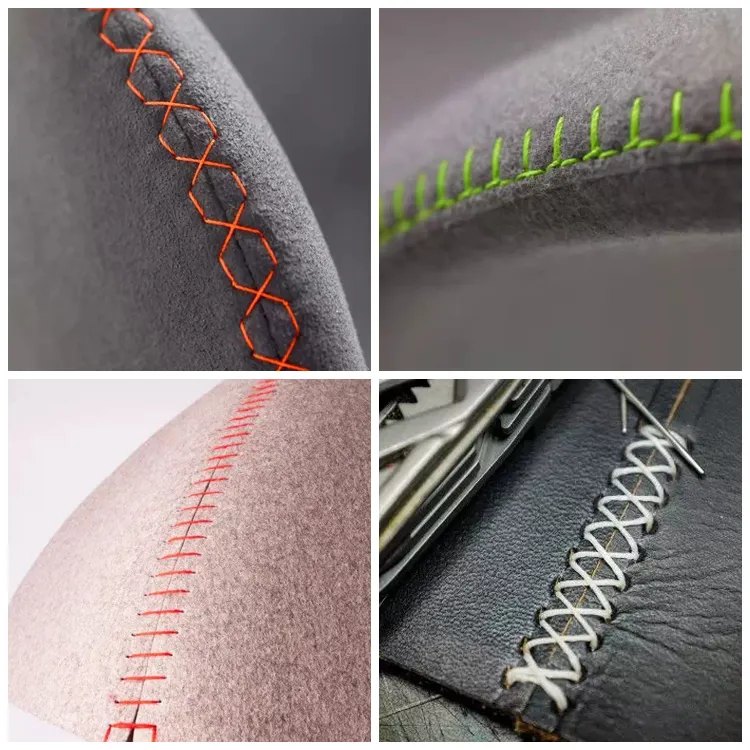

Another key feature is the adjustable stitch length, enabling artisans to alter the distance between stitches according to the specific needs of a project. Longer stitches may be used for decorative purposes, while shorter stitches offer increased security for high-stress areas. Additionally, many saddle sewing machines include specialized attachments, such as edge guides and roller feet, which facilitate the sewing process on uneven or curved edges.

Benefits of Using a Saddle Sewing Machine

One of the primary advantages of utilizing a saddle sewing machine is efficiency. The speed and power of these machines allow users to complete projects in a fraction of the time it would take by hand. This is particularly beneficial for small businesses that rely on meeting deadlines and producing large quantities of goods.

Furthermore, the precision offered by these machines ensures consistent quality across all products. In leather crafting, even minor inconsistencies can lead to product failure or decreased aesthetic appeal. With a saddle sewing machine, artisans can maintain tight tolerances, resulting in professionally finished items that stand the test of time.

Conclusion

The saddle sewing machine is not just a tool but a cornerstone of the leather crafting industry. Its development has enabled craftsmen to push the boundaries of creativity and production, ensuring that both traditional techniques and modern innovations coexist in harmony. As the demand for unique and high-quality leather goods continues to rise, the importance of these machines will only grow. Whether for a professional saddler or an enthusiastic hobbyist, the saddle sewing machine embodies the perfect blend of heritage and technology, keeping the art of leather crafting alive and thriving.

In conclusion, embracing the saddle sewing machine means embracing both history and progress. It is an investment in one's craft, enabling the production of exquisite leather items that reflect skill, quality, and individuality. With continued advancements in technology, the future of saddle sewing remains promising, ensuring that this remarkable tool will remain relevant for generations to come.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025