Sewing Machines for Saddle Assembly and Crafting Techniques

The Art of Saddle Making A Focus on Sewing Machines

Saddle making is an ancient craft that blends tradition with functionality, creating not only a necessary piece of equestrian equipment but also a work of art. The intricate process of saddle making involves various stages, and one of the most critical tools in this trade is the sewing machine specifically designed for leatherwork. This article delves into the significance of sewing machines in saddle making, highlighting their features and advantages.

The Art of Saddle Making A Focus on Sewing Machines

When selecting a sewing machine for saddle making, artisans look for several key features. First and foremost is the machine’s ability to handle thick layers of leather. Saddles are typically constructed from heavy-weight leather, necessitating a robust machine capable of sewing through multiple layers without skipping stitches or damaging the material. Therefore, a walking foot or a compound feed sewing machine is often the preferred choice. These machines provide better control over the leather, allowing for smooth feeding of the material and precise stitching.

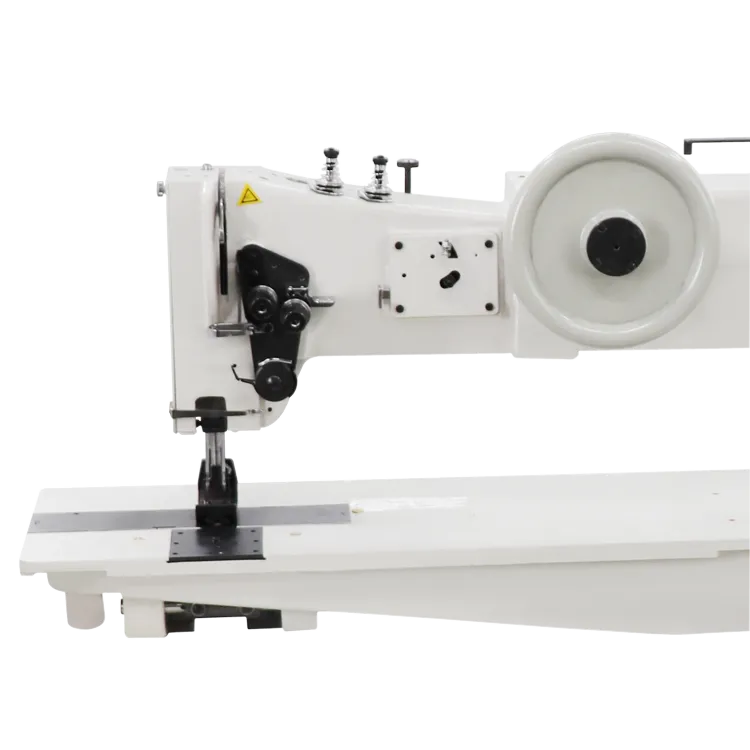

saddle making sewing machine

Another essential feature is the needle and thread compatibility. Saddle makers usually require larger gauges of thread, designed to endure the stresses encountered during riding. Therefore, a sewing machine that can accommodate thicker needles and strong, durable threads—such as polyester or nylon—is essential. This ensures that the seams are not just strong, but also capable of withstanding exposure to the elements over time.

The capability for adjustable stitch length is also an important factor. Different parts of a saddle may require varying stitch lengths for aesthetic and functional purposes. For instance, decorative areas might employ longer stitches, while crucial load-bearing seams will require shorter, tighter stitches to ensure strength. An adjustable stitch allows saddle makers to customize their work to meet specific design requirements.

Moreover, ease of use plays a significant role in the choice of a sewing machine. Saddle makers benefit from machines that have user-friendly interfaces, simplified threading procedures, and readily accessible maintenance features. This enables artisans to focus more on the artistry of saddle making rather than struggle with complex machinery.

In conclusion, the integration of sewing machines into saddle making has revolutionized the craft, merging traditional techniques with modern efficiency. By selecting the right machine—with an emphasis on durability, compatibility with heavy materials, adjustable settings, and ease of use—craftsmen can produce high-quality saddles that not only serve their primary function but also stand out as stunning pieces of craftsmanship. As the equestrian world continues to evolve, the timeless art of saddle making thrives, supported by the innovation of technology in sewing machines. Whether for competitive riders or casual equestrians, the perfect saddle begins with thoughtful design and precise sewing, ensuring that every ride is a comfortable and enjoyable experience.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025