Feb . 13, 2025 14:47

Back to list

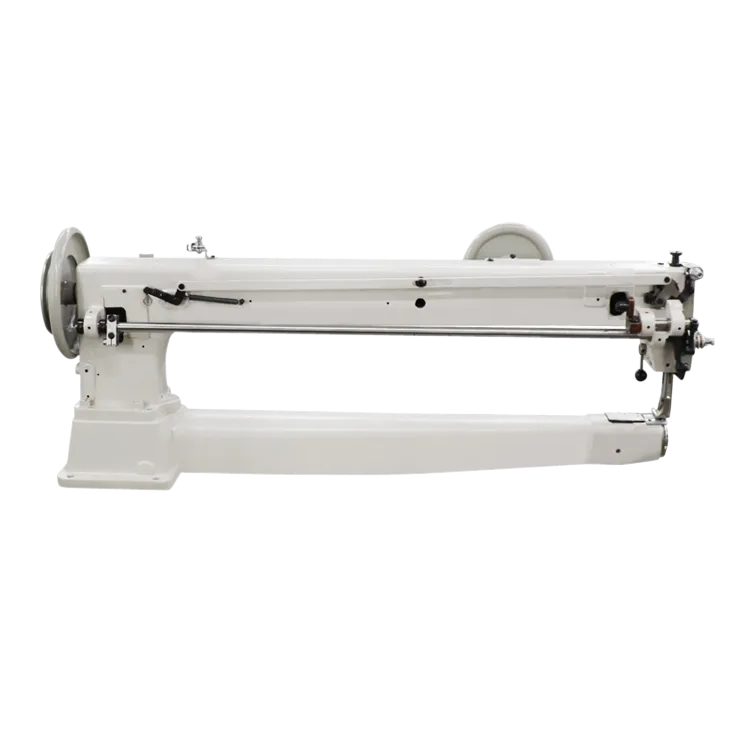

sail making sewing machine

Saddle making is a meticulous craft, honed over centuries, requiring both skill and precision. At the heart of this craft lies a tool indispensable for those serious about saddle making—the saddle making sewing machine. This advanced piece of equipment not only facilitates the sewing process but also significantly enhances the overall quality, durability, and aesthetic appeal of the saddle.

Investing in a saddle making sewing machine signifies a commitment to the craft. It reflects a dedication to producing high-quality, reliable, and aesthetically pleasing saddles. This commitment is especially important for those whose business relies on word of mouth and reputation, as customers in the equestrian community often rely heavily on personal recommendations. A machine that increases both quality and efficiency reinforces an artisan's reputation for excellence. Expertise in using a saddle making sewing machine extends beyond simple operation. Mastery involves understanding the subtle nuances of different leathers and how they interact with specific settings on the machine. Such knowledge often comes from years of hands-on experience, but can be accelerated by seeking training from experienced craftsmen or through workshops focused on saddle making techniques. For those looking to elevate their craft, selecting a saddle making sewing machine from a reputable brand offers peace of mind. Established manufacturers often provide machines that have been tested under various conditions and designed to meet the demands of professional saddle makers. They offer superior after-sales support, including service plans and access to parts, ensuring that your investment lasts for years. Trust in the brand and model you choose is not simply about the machine itself, but the heritage and the support that come with it. Potential buyers should seek reviews and recommendations from seasoned saddle makers, or consult resources provided by equestrian associations to verify the machine's effectiveness and durability. In sum, a saddle making sewing machine is not merely a tool but a cornerstone of the saddle making journey. It embodies the fusion of tradition and technology, enabling artisans to deliver products that resonate with quality and craftsmanship. For those aspiring to reach the apex of saddle making, embracing technology is not optional, but a necessary step towards achieving enduring success and innovation within this storied craft.

Investing in a saddle making sewing machine signifies a commitment to the craft. It reflects a dedication to producing high-quality, reliable, and aesthetically pleasing saddles. This commitment is especially important for those whose business relies on word of mouth and reputation, as customers in the equestrian community often rely heavily on personal recommendations. A machine that increases both quality and efficiency reinforces an artisan's reputation for excellence. Expertise in using a saddle making sewing machine extends beyond simple operation. Mastery involves understanding the subtle nuances of different leathers and how they interact with specific settings on the machine. Such knowledge often comes from years of hands-on experience, but can be accelerated by seeking training from experienced craftsmen or through workshops focused on saddle making techniques. For those looking to elevate their craft, selecting a saddle making sewing machine from a reputable brand offers peace of mind. Established manufacturers often provide machines that have been tested under various conditions and designed to meet the demands of professional saddle makers. They offer superior after-sales support, including service plans and access to parts, ensuring that your investment lasts for years. Trust in the brand and model you choose is not simply about the machine itself, but the heritage and the support that come with it. Potential buyers should seek reviews and recommendations from seasoned saddle makers, or consult resources provided by equestrian associations to verify the machine's effectiveness and durability. In sum, a saddle making sewing machine is not merely a tool but a cornerstone of the saddle making journey. It embodies the fusion of tradition and technology, enabling artisans to deliver products that resonate with quality and craftsmanship. For those aspiring to reach the apex of saddle making, embracing technology is not optional, but a necessary step towards achieving enduring success and innovation within this storied craft.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025