saddle makers sewing machine

The Evolution of Saddle Makers and Their Sewing Machines A Blend of Tradition and Technology

In the world of leatherwork, few crafts are as revered as saddle making. This ancient trade combines artistry, skill, and a deep understanding of materials to create functional and aesthetically pleasing pieces of equipment for horse riders. Central to the transformation of this craft over the years has been the evolution of saddle makers' sewing machines. These machines have not only revolutionized the speed and efficiency of production but also played an indispensable role in preserving the traditional values and artistry associated with saddle making.

The Art of Saddle Making

Saddle making is a time-honored tradition that dates back centuries. The craft requires a profound understanding of both the animal being fitted and the rider's needs. Each saddle must be tailored to ensure comfort, balance, and durability. The process involves selecting high-quality leather, cutting it into precise shapes, and then assembling and stitching the components together. Traditionally, this was accomplished by hand, a painstaking process that required tremendous skill and patience.

However, as demand for saddles grew, particularly with the rise of equestrian sports, there emerged a need for more efficient production methods. This is where sewing machines designed specifically for saddle making began to take center stage.

The Rise of Sewing Machines in Saddle Making

The introduction of sewing machines into the saddle-making process marked a significant turning point. The first dedicated leather sewing machines appeared in the late 19th century. These machines were robust, designed to handle thick layers of leather and heavy thread, and provided saddle makers with the ability to sew faster and more consistently than was possible by hand.

The most significant advancement came with the invention of the walking foot sewing machine, which allowed for superior control over the material being stitched. This innovative feature ensured that multiple layers of thick leather could be sewn together accurately, reducing the likelihood of uneven seams that could lead to structural weaknesses in the finished product.

How Modern Sewing Machines Enhance Traditional Techniques

saddle makers sewing machine

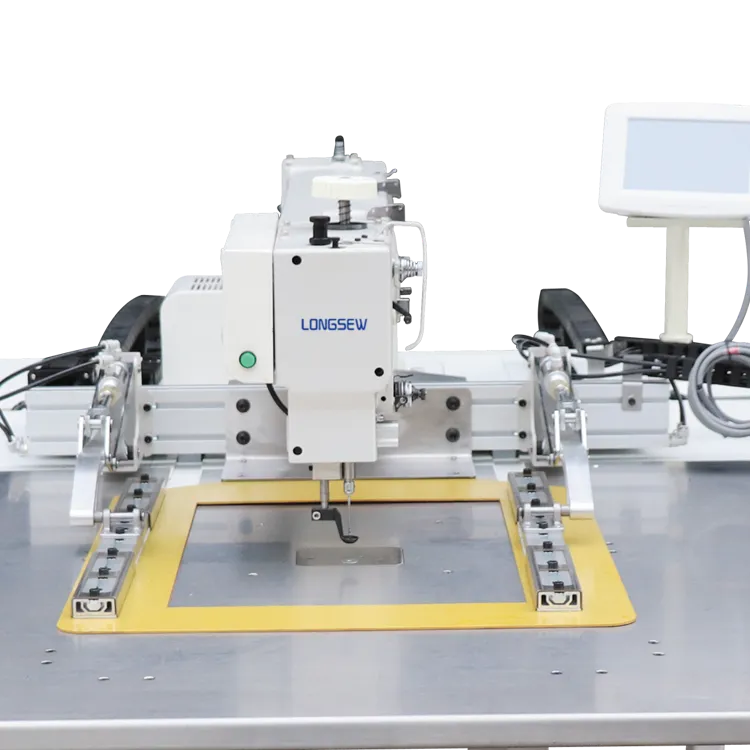

While modern saddle makers still appreciate the artistry involved in their craft, they also recognize the need to integrate technology into their processes. Modern saddle-making sewing machines come with various features designed to improve speed, precision, and overall product quality.

For instance, many contemporary machines are equipped with digital controls that allow for fine-tuning of stitching speed, tension, and stitch length. This precision is particularly important in creating the intricate patterns that are often an integral part of saddle design. Furthermore, heavy-duty machines can accommodate a range of materials, from synthetic leathers to exotic hides, giving saddle makers more options in terms of both functionality and aesthetics.

Additionally, these machines are often equipped with walking feet, needle feed mechanisms, and specialized presser feet that are tailored for sewing thick and multi-layered materials. Such advancements minimize fabric shifting during sewing, ensuring even and strong seams, which are crucial for the durability and performance of the saddle.

Balancing Tradition and Innovation

The relationship between traditional saddle making and modern technology is a delicate balance. Many saddle makers are adamant about preserving the craftsmanship that has defined the trade for generations. They believe that even as machines assist in the sewing process, traditional hand-stitching methods should not be abandoned, especially for final touches or decorative elements that require a personal touch.

Moreover, the philosophy of saddle making extends beyond mere functionality. Each saddle is considered a work of art, with its own story and character. Many artisans will often custom-fit saddles to reflect the rider's unique preferences and needs, emphasizing that while machines may enhance production efficiency, the soul of saddle making is rooted in the skilled hands of the artisan.

Conclusion

Saddle making is a beautiful blend of tradition and modernity. The evolution of sewing machines has undeniably transformed the craft, enhancing the capabilities of artisans while preserving the elemental skills required for high-quality saddle production. As technology continues to evolve, it is paramount that saddle makers retain the artistry that defines their work. This synergy between tradition and innovation not only helps sustain the craft but also ensures that the beautiful art of saddle making continues for future generations.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025