rotary special sewing machine

The Rotary Special Sewing Machine A Revolution in Textile Production

In the world of textiles and garment manufacturing, innovation has always driven efficiency and creativity. Among the plethora of sewing machines available today, one machine stands out for its unique capabilities and remarkable design the rotary special sewing machine. This machine has become a cornerstone not only for its speed and precision but also for its versatility in various sewing applications.

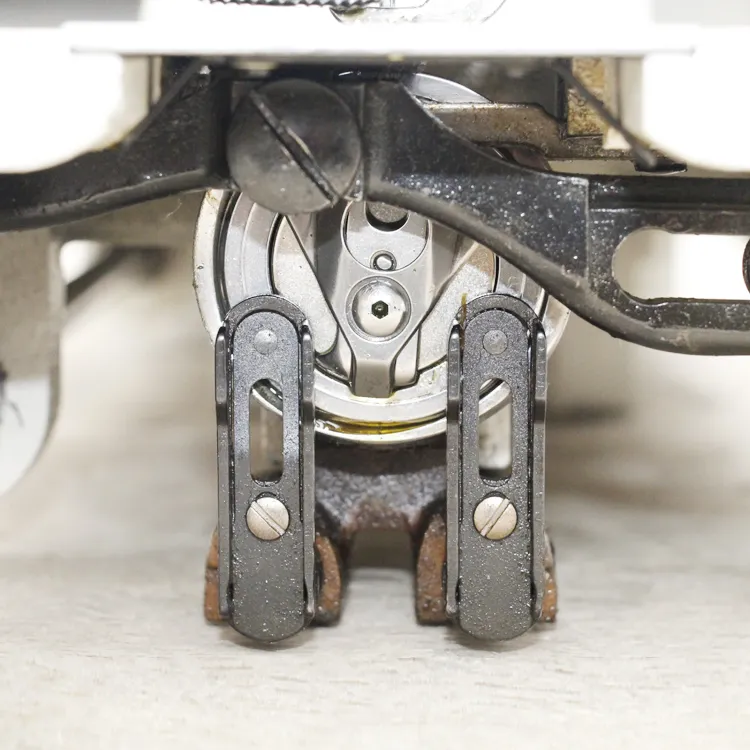

The rotary special sewing machine utilizes a rotating hook mechanism, which enables it to produce a smooth, continuous stitch. Unlike traditional machines that use a stationary hook, the rotary system allows for quicker needle movements and more consistent thread delivery. This mechanism significantly reduces the chances of skipped stitches, making it especially desirable for delicate fabrics and intricate patterns.

One of the primary advantages of the rotary special sewing machine is its speed. With the ability to sew at high RPMs (revolutions per minute), it can greatly enhance productivity in a commercial setting. Fabricators and manufacturers can complete projects faster without sacrificing quality. This efficiency is particularly advantageous in an industry where meeting deadlines is crucial and competition demands constant innovation.

In addition to speed, the rotary special sewing machine is engineered for precision. The machine’s design allows for even tension on the threads, leading to flawless seams and hems. In high-stakes environments such as fashion design or upholstery production, where every detail counts, having a reliable machine that ensures consistent results is invaluable. Seamstresses and tailors can trust that their rotary special sewing machine will deliver perfect stitches every time, allowing them to focus on creativity rather than technical difficulties.

rotary special sewing machine

Versatility is another hallmark of rotary special sewing machines. They excel at handling a variety of fabrics, from lightweight silks to heavy denim, making them suitable for a wide range of projects. Advanced models are equipped with adjustable settings for stitch length and width, allowing users to customize their sewing experience. This flexibility empowers designers and manufacturers to explore new creative avenues and execute complex sewing techniques.

Moreover, rotary special sewing machines have embraced modern technology. Many models now feature computer numerical control (CNC) capabilities that enable automated sewing patterns and designs. This technological advancement not only streamlines the production process but also reduces human error, which is critical in mass production scenarios. As the industry continues to evolve, the integration of technology into sewing machines ensures that manufacturers can keep pace with changing demands and trends.

The ergonomic design of many rotary special sewing machines also contributes to their usability. Features such as adjustable height tables, user-friendly interfaces, and easy-access threading paths minimize physical strain and facilitate a smooth sewing experience. As more people engage in sewing, whether professionally or as a hobby, prioritizing comfort and accessibility plays a significant role in machine design.

As we look towards the future, the rotary special sewing machine remains an essential tool in the textile industry. With ongoing advancements in technology, these machines will continue to evolve, offering even greater efficiency, precision, and adaptability. Whether used in a bustling garment factory or a quaint home studio, the rotary special sewing machine represents a powerful combination of tradition and innovation.

In conclusion, the rotary special sewing machine embodies the essence of progress in sewing technology. Its exceptional speed, precision, versatility, and adaptability set it apart in a crowded market. For those involved in textile production, investing in a rotary special sewing machine is not only a practical choice but also a step towards embracing the future of sewing. As we continue to advance in this industry, the rotary special sewing machine will undoubtedly play a pivotal role in shaping the way we create, design, and manufacture textiles.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025