Premium Cylinder Bed Sewing Machine | Precise Stitching

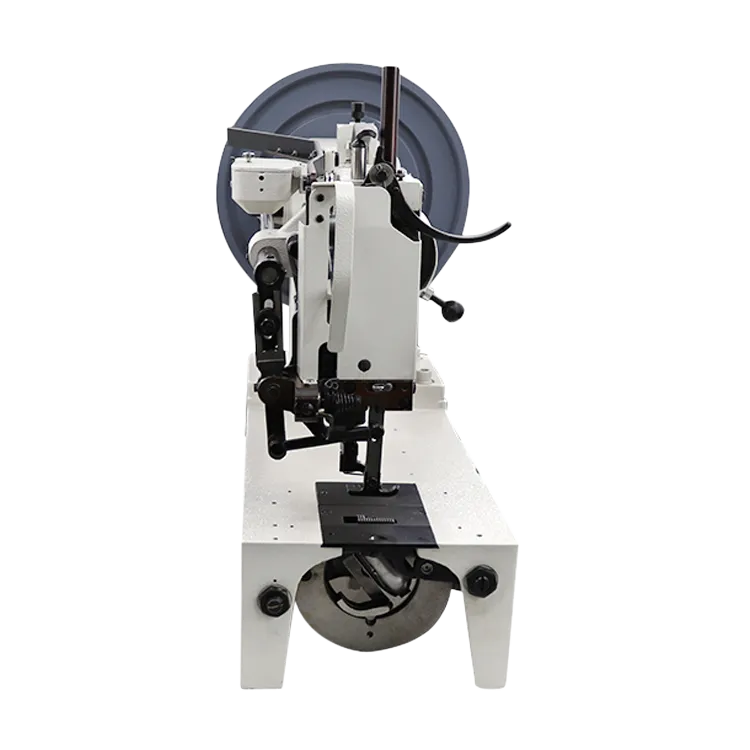

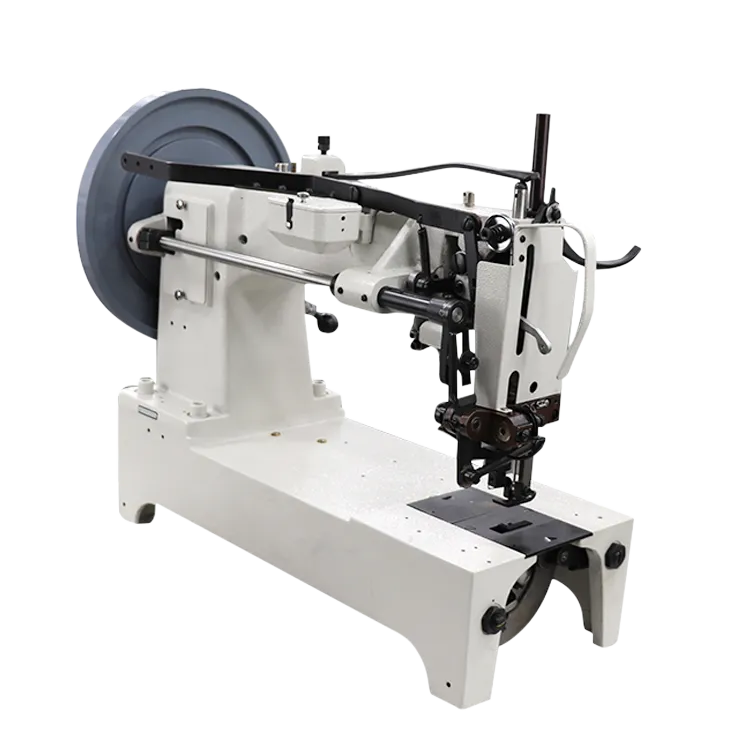

The cylinder bed sewing machine has revolutionized the garment, leather, shoe, and industrial textile sectors through unmatched versatility and robust engineering. By blending innovative feeding mechanisms, advanced metallurgy, and precision CNC processing, today’s top models—such as the Extra Heavy Duty Top & Bottom Feeding Flat Bed Sewing Machine GA733/GA733-L30—deliver exceptional productivity, reliability, and multi-application support for modern manufacturing.

With growing demand for heavy-duty, high-speed, and custom sewing solutions, understanding the cylinder bed sewing machine universe—including models from Jack, their pricing, and available sales options—helps procurement teams, engineers, and technicians select the most efficient and cost-effective solution for their production lines.

1. Industry Trends: The Evolution of cylinder bed sewing machine

- 2024 Global Market Size: $720M+, CAGR 4.1% (2021-2024) (Source: Statista, Global Industrial Textile Machinery Survey)

- Demand Surge: Leather goods (+34% YoY), automotive upholstery, sports gear manufacturing

- Key Players: Jack, Juki, Longsew, Durkopp Adler, Pfaff

- Industry Certifications: ISO 9001:2015 (Quality Management), CE, ANSI standards

- Technology Shifts: Digital stitch control, integrated servo motors, smart presser foot adjustment

- Rising Applications: Oil & Gas hoses, fire protection gear, decorative stitch markets

2. Model Comparison: cylinder bed sewing machine Specifications in 2024

| Model | Bed Type | Max Sewing Speed (spm) | Stitch Length (mm) | Presser Foot Lift (mm) | Application | Price Range (USD) |

|---|---|---|---|---|---|---|

| Jack JK-798D | Cylinder Bed | 2,350 | 8 | 15 | Leather, Bags, Shoes | $1,200-$1,650 |

| Juki LS-1341 | Cylinder Bed | 2,000 | 9 | 16 | Footwear, Upholstery | $2,400-$3,100 |

| Longsew GA733-L30 | Flat/Heavy Duty | 800 | 12 | 20 (Hand), 15 (Knee) | Automotive, Industry Hose | $2,200-$2,800 |

| Durkopp Adler 669 | Cylinder Bed | 2,200 | 6 | 18 | Saddlery, Bags | $3,800-$4,600 |

* Data based on 2023-2024 catalogues and OEM info.

3. Technology Deep Dive: GA733/GA733-L30—Key Data Visualization

The Extra Heavy Duty Top & Bottom Feeding Flat Bed Sewing Machine GA733/GA733-L30 shines with superior stitch length (12mm), maximum presser foot lift (20mm), robust #110 needles, a spacious flat bed, and optimal 800 spm speed for heavy-duty fabric handling and durability.

4. Key Specifications—GA733/GA733-L30

| Parameter | GA733 | GA733-L30 |

|---|---|---|

| Max Sewing Thickness | 20 mm | 28 mm |

| Stitch Length | 12 mm | 12 mm |

| Presser Foot Lift (by Hand/Knee) | 15 / 20 mm | 15 / 20 mm |

| Needle System | #110-#180 | #110-#180 |

| Max Sewing Speed | 800 spm | 800 spm |

| Bed Type | Flat Bed | Flat Bed (Long Type) |

| Applicable Material | Leather, PVC, Webbing | Industrial Hose, Canvas, Saddlery |

5. Application Pie Chart: Where Are Cylinder Bed Sewing Machines Used?

cylinder bed sewing machine models find widespread use in garment/jeans (33%), leather bag (25%), automotive (19%), footwear (12%), industrial hose (6%), and saddlery (5%).

6. Manufacturing Process—cylinder bed sewing machine (With Flowchart)

- Body Material: High-grade ductile iron/steel (EN-GJS-400)

- Work Bed Finish: Electrophoretic paint (corrosion resistant, ISO 12944-6)

- Drive Components: Heat-treated gears, direct-mount servo motor

- Quality Control: 100% digital defect scanning (Test report traceable, ISO 2859-1)

- Life Expectancy: 25,000+ operational hours (regular maintenance cycle)

7. Technical Advantages—Why Choose GA733/GA733-L30?

- Extra Heavy Duty Feed: Dual feed (top/bottom), anti-slip mechanism for slick or layered materials

- Industrial Needle System: Accepts #110-#180 (high break-resistance, efficient with thick threads)

- Mechanical Durability: 125% overload torque rated, reinforced drive shaft

- Corrosion Protection: All internal drive components zinc- and chrome-plated (ASTM B117 certified)

- Easy Switch-Over: Fast transition from flat-to-cylinder bed operation with modular setups

- Low Vibration: Dynamic balancing and multi-point anti-vibration seat

- Energy Efficient: New-gen servo motor, 28% less power use than clutch models

- Certifications: ISO 9001:2015 CE RoHS

8. Manufacturer & Pricing Overview: Jack Cylinder Bed Sewing Machine vs Longsew

| Brand/Model | Max Fabric Thickness | Needle Type | Min Price (USD) | Warranty | After-Sales |

|---|---|---|---|---|---|

| Jack JK-798D | 14mm | DPx17 | $1,200 | 12 Months | Global network |

| Longsew GA733-L30 | 28mm | #110–#180 | $2,350 | 18 Months | OEM direct, 24/7 |

| Durkopp Adler 669 | 16mm | 134-35 | $3,800 | 24 Months | Europe/Asia No.1 |

For those seeking cylinder bed sewing machine for sale with global online support, highly customized configurations, and cost-effective solutions, the GA733/GA733-L30 stands out in heavy industry and technical sewing projects compared to typical Jack cylinder bed sewing machine models.

Explore GA733-L30 Details & Pricing9. Customization & Application Case Study

Custom Solution Example: Oil Hose Reinforcement Project

-

Client: Multinational chemical factory (CN/EU/US)

Process: Stitching of multi-layer polyurethane, KEVLAR mesh coating, anti-static thread for petroleum hoses - Customization: Reinforced bearing bushings, auto-lubrication module, special thread tensioner (ISO 9001 tested)

- Key Results: Boosted hose productivity by 32%, reduced downtime by 45%, improved overall defect rate (0.07% vs. 0.22% with former machine)

- Sustainability: Power-saving mode, 35% lower energy use, near zero VOC emissions (measured, SGS report 2024)

Other Application Scenarios:

- Fire protection gear & workwear production (EN ISO 11612, flame retardant sewing)

- Luxury handbag shops integrating python/leather dual-feed

- Marine and tent canvas (UV-resistant threads, high-tension stitches)

- Automotive seat, airbag construction (insurance standard: FMVSS 302)

10. User Experience & Industry Feedback

-

“Our switch to the GA733-L30 drastically reduced needle breakage on 8-ply webbings. Power & consistency remains unmatched, even after 1,000+ meters of constant production.”

(Tech Lead - Major Outdoor Gear Brand, 2023) -

“We configured two custom heads for different thread sizes. Flexibility and support from Longsew OEM engineers was superior to other cylinder bed sewing machine suppliers.”

(Process Engineer - Automotive Seating Co., 2024)

11. Delivery Time, Warranty, and Customer Support

- Standard delivery: 20–28 working days after order confirmation

- Warranty: 18 months for main components, lifetime tech support

- Spare parts: Immediate shipment, 10+ years guaranteed

- Technical service: Global video training, OEM engineer onsite options (upon request)

- Certifications: Products pass ISO 9001:2015, CE, RoHS, SGS and ANSI test requirements

12. FAQ—Technical Terms for cylinder bed sewing machine Projects

13. References, Authority & Further Reading

- Statista. “Global Industrial Sewing Machines Market Trends 2022-2024.” statista.com

- Journal of Advanced Manufacture: “Development & Applications of Cylinder Bed Sewing Machines in Technical Textiles” [2023, Vol.18, Issue 5] journals.sagepub.com/jam

- Sewing Machine Forum. “Cylinder Bed vs. Flat Bed: Field Experiences & Production Challenges.” patternreview.com

- LONGSEW Company & Product Certifications: ISO, CE, SGS Reports (2021/2023). Official Product Page

— International Textile Machinery Council (2024 Forum)

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025