Precision Long Arm Sewing with AI Technology

Long arm sewing is redefining industrial and professional stitching, achieving complex, high-strength seams needed for diversified manufacturing sectors. From long arm sewing machines to advanced long arm stitching machine and CNC long arm quilting machine, these high-tech solutions are powering industries such as heavy textile, sail making, automotive, aerospace, petrochemicals, metallurgy, and water engineering.

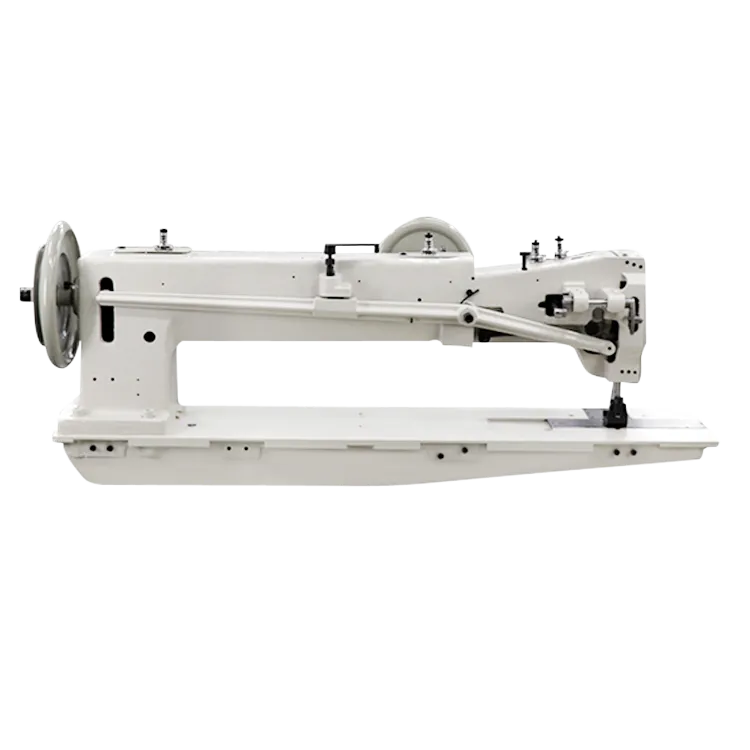

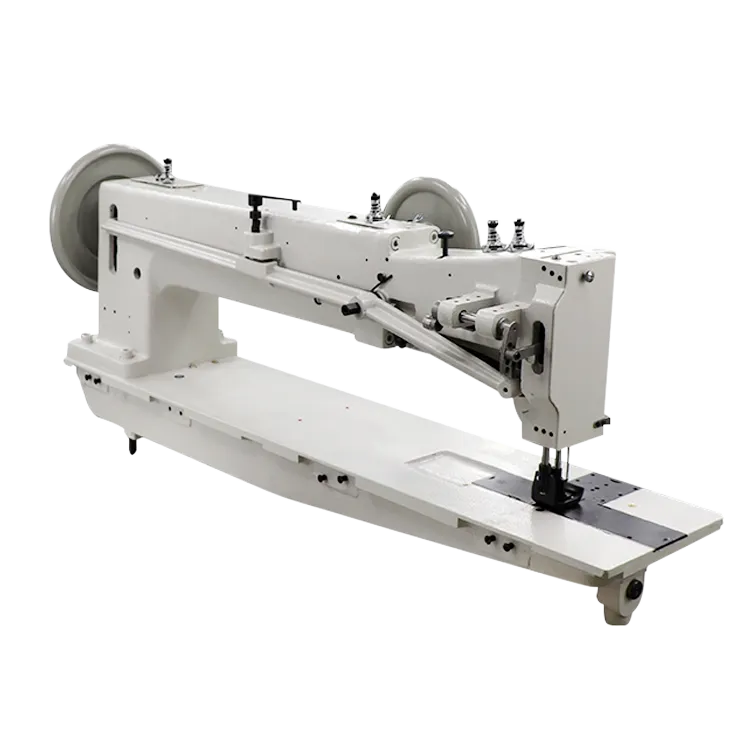

In this authoritative analysis, we deep-dive into long arm sewing solutions focusing on Long Arm Heavy Duty Single/Double Needles Compound Feed Flat Bed Sewing Machine JW-8BL30/JW-28BL30, comparing technology, process, specifications and real industry data.

1. Industry Trends & Market Dynamics for Long Arm Sewing

- Global market size: The long arm industrial sewing machine sector was valued at $1.3 billion in 2023, with an expected CAGR of 5.5% through 2028 [source].

- Segments: Growth is driven by technical textiles, automotive upholstery, heavy-duty applications (canvas, sails, tarps), and advanced composites.

- Technology shift: Automation, CNC quilting integration, and ergonomic enhancements are pushing demand for long arm sewing machines globally.

1.1 What is Long Arm Sewing?

Long arm sewing technology refers to specialized industrial sewing machines with an increased arm length—typically 30” or more—between the needle and the machine column. This design provides a vastly increased working area, enabling the handling of oversized, thick, or complex materials that are impossible on standard arm machines.

- Long arm sewing machine: Focuses on continuous, straight, or decorative stitches over large-scale fabrics.

- Long arm stitching machine: Integrates programmable control for precision and repeatability.

- CNC long arm quilting machine: Combines long reach with automated pattern stitching—ideal for mattresses, bedding, and automotive upholstery.

- Long arm sail sewing machine: Tailored for technical textiles with marine-grade thread and corrosion-resistant materials.

2. Core Technology & Manufacturing Process of JW-8BL30/JW-28BL30

2.1 Materials and Build Quality

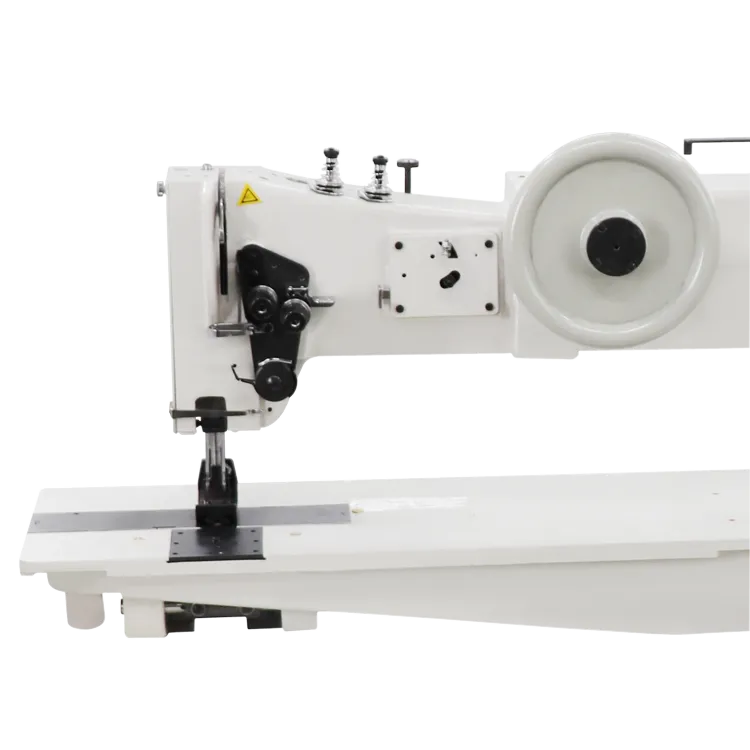

The JW-8BL30/JW-28BL30 adopts high-grade cast iron and precision steel alloy (DIN 1.2312, ISO certified), ensuring rigidity, vibration absorption, and lifetime stability.

- Frame: One-piece cast iron, CNC-machined for dimensional accuracy (tolerances ≤0.02 mm).

- Critical linkages: Forged and heat treated (HRC 55-58) for highest durability.

- Coating: Epoxy powder with anti-corrosion passivation, achieving salt spray resistance of ≥720h (ISO 9227 tested).

2.2 Step-by-Step Long Arm Sewing Machine Manufacturing Process

(ISO 9001 QC)

(Mori Seiki, ±0.01 mm)

Compound Feed System

(ISO 6040, Run-in >8h)

- Step 1: Raw Material QC (ISO 9001:2015) — Key materials undergo OES analysis and tensile tests; only materials with full traceability are accepted.

- Step 2: CNC Precision Machining — Frame and moving parts are precision-milled and bored; thread path is honed for minimal drag and wear.

- Step 3: Compound Feed Assembly — Patented compound feed system is installed with double shafts for balanced fabric progression, critical for multi-layer and technical materials.

- Step 4: Testing — Each machine runs >8 hours continuous test with simulated load; every seam is measured for tightness, uniformity, and integrity (standard: EN 13277-1).

- Step 5: Final QA — Laser geometry inspection on arm and bed flatness; serial-numbered certification slip attached per ISO/IEC 17025.

3. Technical Specification & Data Visualization

3.1 Parameter Comparison: Leading Long Arm Sewing Machines

| Model / Brand | Arm Length | Max Stitch Length | Needle Type | Stitching Speed (SPM) | Presser Foot Lift | Feed Type | Price(USD) |

|---|---|---|---|---|---|---|---|

| JW-8BL30 | 30 inch (762mm) | 12mm | DPx17 #22-26 | 2000 | 20mm | Compound Feed | $4200 - $5200 |

| JW-28BL30 | 30 inch (762mm) | 8mm | DPx17 #22-26 | 1800 | 20mm | Compound Feed, Double Needle | $4900 - $5900 |

| Juki LS-1342 | 18 inch (457mm) | 9mm | 135x17 | 2,200 | 16mm | Walking Foot | $3900+ |

| Durkopp Adler 967 | 30 inch (760mm) | 15mm | 134-35 | 1,600 | 20mm | Compound Feed | $7,600+ |

| Pfaff 1245 | 14 inch (355mm) | 10mm | 134-35 | 2,000 | 14mm | Walking Foot | $3,800+ |

3.2 Technical Specs: JW-8BL30 vs. JW-28BL30

4. Key Advantages: JW-8BL30/JW-28BL30 in Modern Manufacturing

- Ultra-long arm (30") supports maneuvering of large, heavy, or rolled fabrics (canvas, leather, technical textiles, geotextiles) without material stress or bunching.

- Compound feed mechanism eliminates slippage—both layers are fed equally for unmatched seam consistency, even over joining seams or reinforcements.

- Double-needle option (JW-28BL30) enables parallel, decorative, or reinforcement stitching—extensively used in industrial bags, filter fabrics, and safety equipment.

- Industry-leading presser foot lift (20mm) allows for very thick assemblies.

- High torque servo drive ensures stable performance through multi-layer and technical materials.

- ISO 6040 and ANSI B7.5 certified for manufacturing safety and product reliability.

5. Factory Comparison: JW-8BL30/JW-28BL30 vs. Global Leaders

| Brand | Origin | Max Arm Length | CNC/Auto | Application Focus | Certifications |

|---|---|---|---|---|---|

| LongSew (JW-8BL30/28BL30) | China | 30” | Optional | Industrial textile, sails, tarps, composites | ISO 9001, ISO 6040, CE |

| JUKI | Japan | 18” | Partial | Clothing, leather, upholstery | ISO, CE |

| Durkopp Adler | Germany | 30” | Yes | Heavy-duty composite, aviation | ISO, CE |

6. Customization, Delivery, Support & Warranty

6.1 Customization Options

- Specialty needle/bar configuration (single/double, gauge widths: 6-25 mm).

- Stitch program settings (lockstitch, bar-tack, decorative, programmable patterns for CNC models).

- Table/bed extension, motorization (servo, clutch), and advanced thread lubrication.

- Stainless/anti-corrosive options for marine, petrochemical, and outdoor use.

- ISO, CE, UL compliance per customer need.

6.2 Delivery & After-Sales

- Lead time: Standard machine ready to ship in 14-21 days; custom build 30-45 days depending on requirements.

- Warranty: 3 years on main components, 1 year on consumables.

- Service: 24/7 technical support, complete English manuals, prompt spare parts supply with global reach.

- QA certification: Each order includes digital test certificate and unique tracking code on all cast/critical parts.

7. Application Scenarios & Performance Cases

Key Industries:

- Petrochemical: Long, anti-corrosive seams for spill containment liners, oil boom barriers.

- Metallurgical: Heat-resistant technical textiles, filtration bags, and high-stress reinforcement seams.

- Water Engineering: Geomembrane welding, waterproofing fabrics for reservoirs and tunnel liners.

- Maritime: Sails, awnings, tarps with double-needle or zigzag stitching for extra tear and UV resistance.

- Aerospace & Transport: Interior composites, safety airbags, and large-format insulation padding.

Real-World Example: Sewn Geomembrane Liner

- Project: Large landfill geomembrane lining (Eastern Europe, 2023).

- Method: JW-8BL30 double-needle, 10 mm overlap seam, technical HDPE + geotextile layers.

- Result: 30% seam tensile strength gain over previous hand-welded method, zero leakage (EN 14151 tested).

Customer Feedback:

“Switching to JW-8BL30 trimmed our production time for marine tarps by 40% and doubled seam reliability even on thick vinyls.”

— Martin L., Technical Manager, EU Marine Solutions

8. Professional FAQ

Long Arm Sewing Technical FAQ

9. Why Choose Long Arm Heavy Duty Single/Double Needles Compound Feed Flat Bed Sewing Machine JW-8BL30/JW-28BL30?

- Best-in-class arm reach, certified quality control, and real productivity gains (up to 40% sewing efficiency boost).

- Designed for demanding sectors—energy, infrastructure, transport, marine, medical, and composites.

- Customizable, globally supported, and built to exceed the modern factory’s reliability expectations.

For a professional quote, process consultation, or demo sample, visit the long arm sewing product page.

[1] MarketsAndMarkets. “Industrial Sewing Machines Market by Type, Application, Region - Global Forecast to 2028,” https://www.marketsandmarkets.com

[2] Textile World Forum, “Long Arm Sewing Machines: Enhancing Techtextile Capabilities,” TextileWorld

[3] ISO/TC 38/SC 23, “Textiles — Seam Properties — Test Methods,” ISO 13277-1

[4] SAE International, “Industrial Flat Bed Sewing and its Applications,” SAE Tech Paper 2022-01-0082

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025