PP Woven Sack Bag Stitching Machine for Efficient Packaging Solutions

The Essential Role of PP Woven Sack Bag Sewing Machines in Modern Manufacturing

In the ever-evolving landscape of manufacturing, the demand for efficient and durable packaging solutions is paramount. One of the most widely used materials in this domain is polypropylene (PP), which has become a staple for producing woven sack bags. These bags are utilized across various industries, including agriculture, construction, and retail, for their strength, versatility, and cost-effectiveness. However, producing these bags efficiently requires specialized machinery, specifically, PP woven sack bag sewing machines.

Understanding PP Woven Sack Bags

PP woven sacks are made from woven polypropylene fibers, a type of plastic. They are well-known for their robustness and resistance to environmental factors such as moisture and UV rays. This makes them ideal for storing and transporting bulk goods like grains, fertilizers, chemicals, and other products that require secure packaging. Their lightweight nature further enhances their appeal, allowing for easier handling and transportation.

The Importance of Sewing Machines

The production of PP woven sack bags involves several steps, including weaving, cutting, and sewing. While weaving forms the primary structure of the bags, it is the sewing process that ensures their durability and functionality. PP woven sack bag sewing machines play a crucial role in this process by stitching the edges of the bags, thereby preventing fraying and ensuring that the contents remain secure during transit.

These machines are designed to handle the unique challenges posed by PP materials. They are equipped with heavy-duty needles and thread that can penetrate the thick, woven fibers of the sacks. The sewing machines also feature strong motors that provide the necessary power to handle the demanding production speeds associated with large-scale manufacturing.

Features of Modern PP Woven Sack Bag Sewing Machines

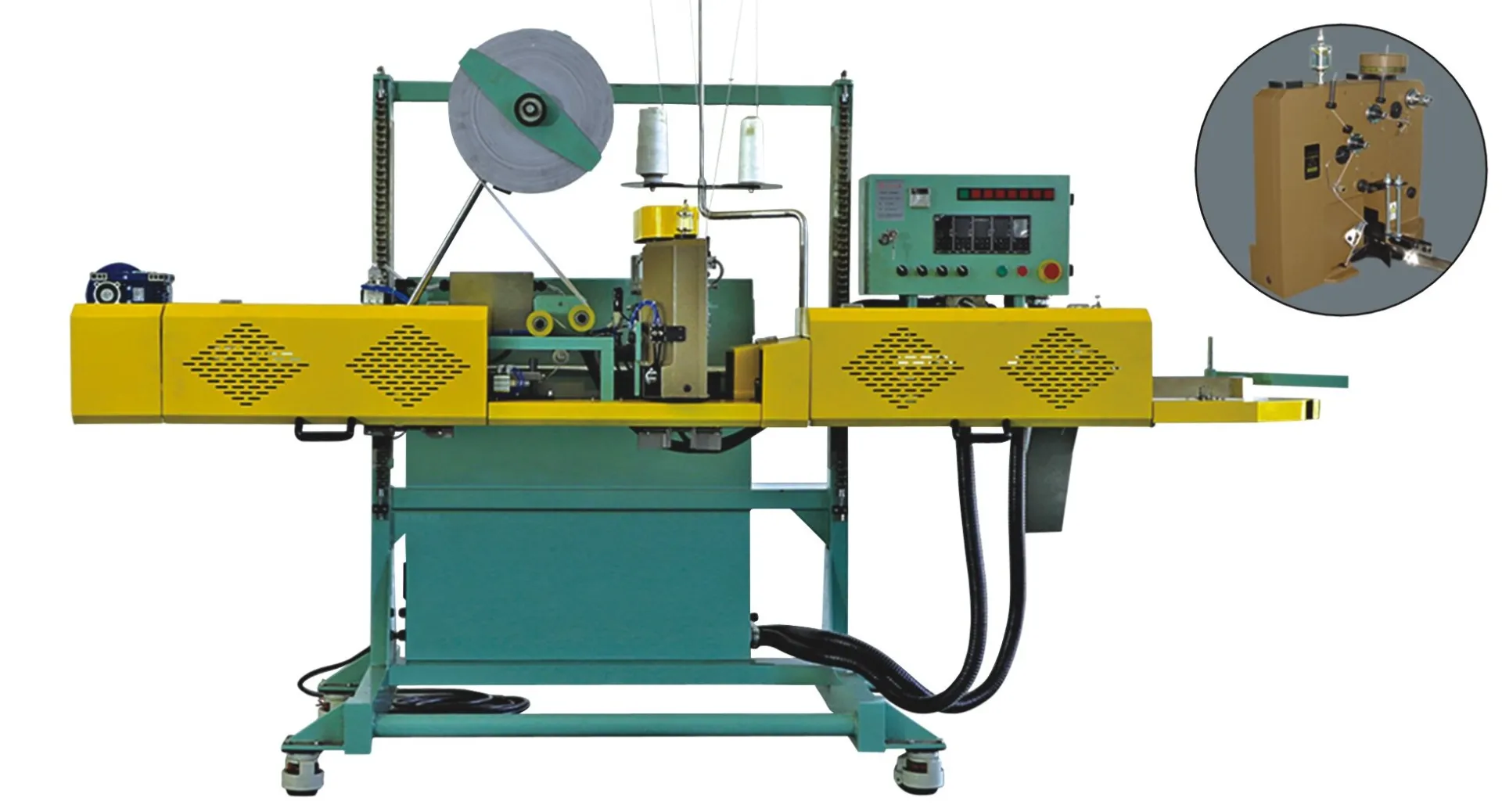

pp woven sack bag sewing machine

Modern PP woven sack bag sewing machines come with various advanced features that enhance their efficiency and ease of use. For instance, many machines include programmable logic controllers (PLCs) that allow operators to set specific sewing patterns and adjust speeds according to production needs. This automation not only speeds up the process but also ensures consistent quality across batches.

Furthermore, some machines incorporate automatic threading systems that reduce downtime caused by manual threading. This feature is particularly valuable in high-volume settings where efficiency is critical. Additionally, modern machines often come with built-in sensors that detect any sewing errors or defects, enabling immediate corrections and minimizing waste.

The Economic Impact

Investing in high-quality PP woven sack bag sewing machines can significantly impact a manufacturer’s bottom line. By increasing production efficiency and reducing material waste, manufacturers can optimize their operations and enhance profitability. Furthermore, high-quality sewn bags lead to greater customer satisfaction, as they are more likely to meet the rigorous standards required for packaging various products.

Additionally, as sustainability becomes an increasingly important focus globally, manufacturers are also turning to PP woven sack bags made from recycled materials. The demand for eco-friendly packaging solutions is rising, driving manufacturers to adapt their processes and invest in versatile sewing machines capable of handling different materials without compromising on quality.

Conclusion

In conclusion, PP woven sack bag sewing machines are indispensable tools in the manufacturing of durable and reliable packaging solutions. As industries continue to recognize the value of PP woven sacks, the demand for advanced sewing machines will only grow. By investing in state-of-the-art sewing technology, manufacturers can enhance their production capabilities, improve product quality, and achieve a competitive edge in the market. Embracing these innovations not only leads to greater efficiency but also supports the broader goals of sustainability and responsible manufacturing.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025