Feb . 14, 2025 19:58

Back to list

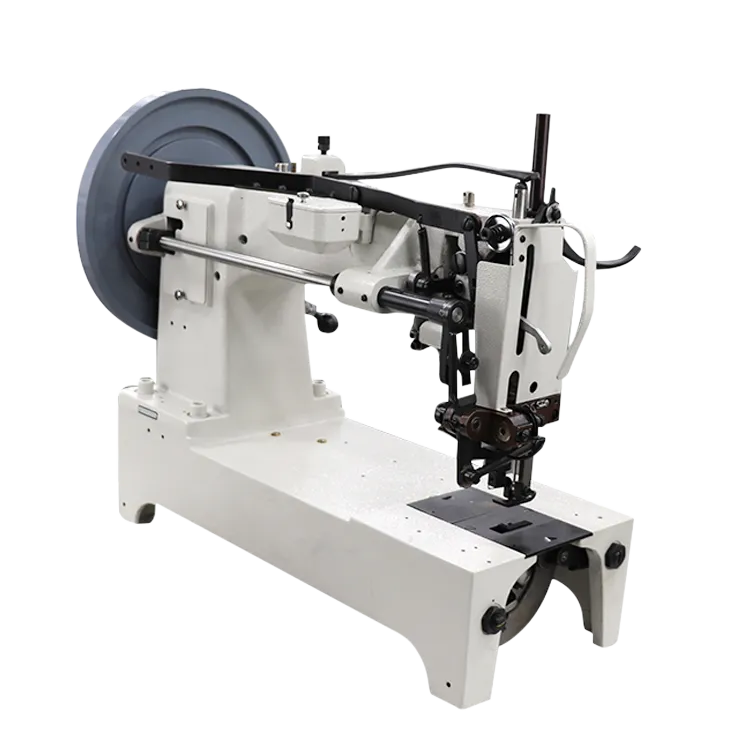

Fishing Net Hauling Rope Single Needle 3 Threads Overedging Sewing Machine 81500CZ

In the ever-evolving world of industrial sewing, the PP woven sack bag sewing machine holds a distinct position as an essential tool for businesses focused on packaging and material handling solutions. Its significance in the industry cannot be overstated, as it provides the precision, efficiency, and reliability necessary for producing high-quality woven sacks, a staple in industries ranging from agriculture to construction.

The pursuit of efficiency in production lines can make or break a business. An investment in PP woven sack bag sewing machines aligns with the strategy to improve both throughput and product quality. Seek advice from industry experts and manufacturers with a track record of providing robust, reliable machinery. Testimonials and case studies from peers in the industry can provide first-hand insight into the machine's applications and potential pitfalls. Ensure the supplier offers comprehensive after-sales support services, including training and maintenance programs. Building a strong relationship with trusted experts not only facilitates the immediate implementation but also ensures long-term operational success. Real-world Applications and Experience In practice, the PP woven sack bag sewing machine has demonstrated its value across different sectors. Agricultural enterprises use these machines to package seeds and fertilizers efficiently, optimizing storage space and enhancing transport logistics. In construction, these machines are instrumental in manufacturing sandbags and cement bags, essential for creating secure and durable storage solutions. The testament to their effectiveness is visible in neatly sewn bags that withstand the rigors of handling and transport. A Commitment to Sustainable Practices Incorporating sustainable practices into business operations is no longer optional but a necessity. The use of PP woven sack bag sewing machines supports this objective by reducing material waste and enhancing the reusability of packaging. Modern machines frequently feature energy-saving technologies and produce minimal emissions, aligning with global sustainability goals and reducing the overall carbon footprint. Ultimately, proficiency in utilizing PP woven sack bag sewing machines depends on aligning the technical features to organizational goals, investing in operator training, and maintaining strong supplier relationships. Through this comprehensive approach, businesses can achieve substantial improvements in their packaging capabilities, ensuring they remain competitive in a rapidly developing sector.

The pursuit of efficiency in production lines can make or break a business. An investment in PP woven sack bag sewing machines aligns with the strategy to improve both throughput and product quality. Seek advice from industry experts and manufacturers with a track record of providing robust, reliable machinery. Testimonials and case studies from peers in the industry can provide first-hand insight into the machine's applications and potential pitfalls. Ensure the supplier offers comprehensive after-sales support services, including training and maintenance programs. Building a strong relationship with trusted experts not only facilitates the immediate implementation but also ensures long-term operational success. Real-world Applications and Experience In practice, the PP woven sack bag sewing machine has demonstrated its value across different sectors. Agricultural enterprises use these machines to package seeds and fertilizers efficiently, optimizing storage space and enhancing transport logistics. In construction, these machines are instrumental in manufacturing sandbags and cement bags, essential for creating secure and durable storage solutions. The testament to their effectiveness is visible in neatly sewn bags that withstand the rigors of handling and transport. A Commitment to Sustainable Practices Incorporating sustainable practices into business operations is no longer optional but a necessity. The use of PP woven sack bag sewing machines supports this objective by reducing material waste and enhancing the reusability of packaging. Modern machines frequently feature energy-saving technologies and produce minimal emissions, aligning with global sustainability goals and reducing the overall carbon footprint. Ultimately, proficiency in utilizing PP woven sack bag sewing machines depends on aligning the technical features to organizational goals, investing in operator training, and maintaining strong supplier relationships. Through this comprehensive approach, businesses can achieve substantial improvements in their packaging capabilities, ensuring they remain competitive in a rapidly developing sector.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025