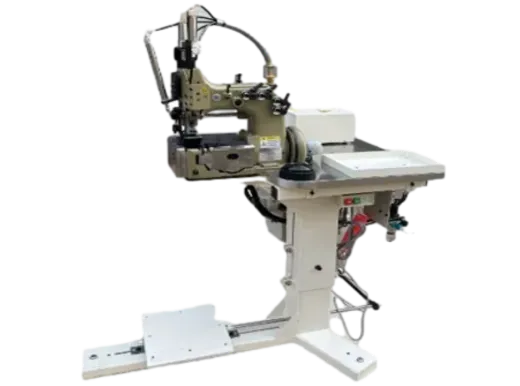

pp woven bag stitching machine

The Importance of PP Woven Bag Stitching Machines in Modern Manufacturing

In today’s fast-paced manufacturing environment, efficiency, durability, and versatility are key factors that companies must consider to remain competitive. One of the critical components in the production of packaging materials is the PP (polypropylene) woven bag stitching machine. As the demand for eco-friendly packaging solutions continues to grow globally, understanding the role of these machines in manufacturing processes becomes increasingly important.

What Are PP Woven Bags?

PP woven bags are made from woven polypropylene, a type of plastic that is both lightweight and durable. These bags have gained immense popularity in various industries due to their strength and ability to resist moisture and chemicals. They are commonly used for packaging agricultural products, chemicals, construction materials, and even pet food. The versatility of PP woven bags makes them an essential product for businesses looking for sustainable packaging options.

The Role of Stitching Machines

The stitching of PP woven bags is a crucial step in the production process. A PP woven bag stitching machine automates the process of closing and securing the bags once they are filled with their respective products. This automation significantly increases production speed and efficiency, enabling manufacturers to meet rising demand without compromising on quality.

Modern stitching machines are designed to cater to a variety of bag sizes and shapes, making them adaptable to different manufacturing needs. Their ability to provide precise and consistent stitching ensures that the bags can withstand the rigors of transportation and storage.

Advantages of Using PP Woven Bag Stitching Machines

1. Increased Efficiency Automated stitching machines can work much faster than manual stitching methods. This increased speed leads to higher output, enabling manufacturers to keep up with market demands.

2. Cost-Effectiveness While the initial investment in stitching machinery may be significant, the long-term savings are substantial. Reduced labor costs and minimized material waste contribute to a healthier bottom line.

pp woven bag stitching machine

3. Consistency and Quality Automated machines provide consistent stitching quality, which is difficult to achieve through manual labor. This consistency minimizes the risk of bag failure during handling and transportation.

4. User-Friendly Operation Most modern PP woven bag stitching machines come equipped with advanced technology, making them easy to operate. Many models feature user-friendly interfaces and programmable settings, allowing operators to quickly adapt to different production runs.

5. Enhanced Safety Automating the stitching process reduces the number of workers needed on the production floor, which can lead to safer working conditions. Less manual handling means a lower risk of injury from repetitive tasks related to stitching.

6. Flexibility and Customization Many stitching machines can be customized to suit specific production requirements. This flexibility allows manufacturers to cater to diverse client needs, producing a range of bag types from standard sizes to custom dimensions.

The Future of PP Woven Bag Stitching Machines

As the demand for eco-friendly and sustainable packaging solutions continues to rise, the PP woven bag market is expected to grow significantly. This shift will drive innovations in stitching technology, focusing on improving speed, efficiency, and environmental impact. Manufacturers are likely to invest in smarter machines that incorporate features like IoT connectivity for real-time monitoring, allowing for predictive maintenance and reduced downtime.

Moreover, the development of biodegradable and recyclable materials will also influence the evolution of PP woven bag stitching machines. Manufacturers will need to adapt their processes to accommodate new materials without compromising on the quality and integrity of the final product.

Conclusion

In conclusion, PP woven bag stitching machines play a vital role in modern manufacturing, particularly for industries seeking efficient, robust, and eco-friendly packaging solutions. Understanding their advantages and the technological advances surrounding these machines can help businesses maximize productivity and stay competitive in a rapidly evolving market. As sustainability becomes an even larger focus, the future of PP woven bag production—and the machines that facilitate it—looks promising, paving the way for innovation and growth in the industry.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025