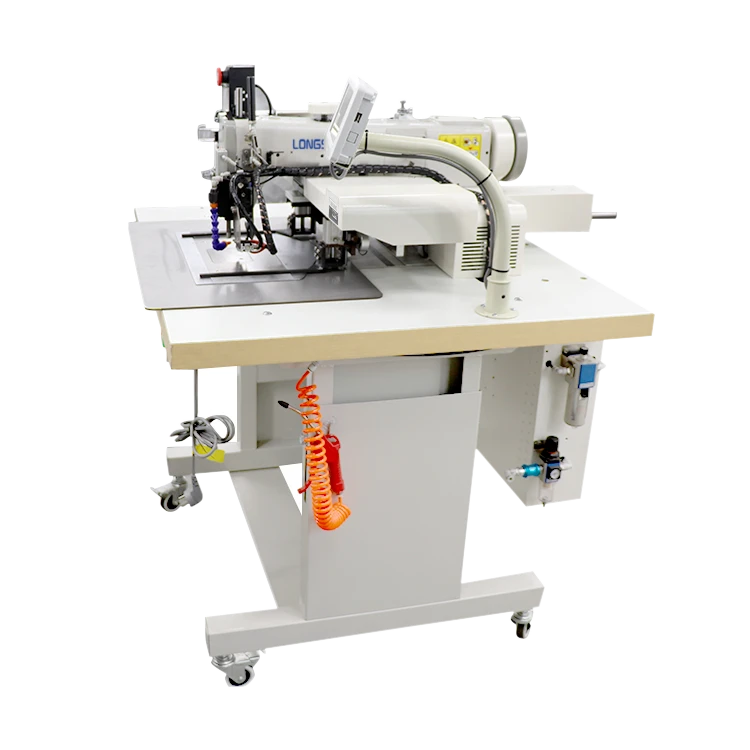

pp woven bag stitching machine

The Importance of PP Woven Bag Stitching Machines in Modern Manufacturing

In the rapidly evolving landscape of industrial manufacturing, the efficiency of packaging processes plays a crucial role in the overall productivity of businesses. Among the various packaging materials used today, polypropylene (PP) woven bags are gaining significant popularity due to their strength, durability, and versatility. However, the effectiveness of these bags largely depends on the quality of their construction, which is where PP woven bag stitching machines come into play.

What are PP Woven Bags?

PP woven bags are made from a strong and lightweight fabric, produced by weaving polypropylene strands. These bags are commonly used for packaging products like grains, fertilizers, seeds, and other agricultural produce. Their resistance to moisture, UV rays, and tearing makes them an excellent choice for both indoor and outdoor storage. To ensure that these bags serve their intended purpose effectively, high-quality stitching is imperative.

The Role of Stitching Machines

PP woven bag stitching machines are designed to provide robust stitching solutions to ensure the integrity of the bags. These machines utilize high-speed stitching methods, employing advanced technology to enhance precision and efficiency. Here are some critical aspects of PP woven bag stitching machines that highlight their importance in the manufacturing sector

1. Efficiency and Speed One of the primary advantages of these machines is their ability to stitch bags at high speeds. This efficiency is crucial in meeting the demands of large-scale production without compromising on quality. A faster stitching process translates to shorter lead times and increased output, allowing companies to maximize their operational potential.

pp woven bag stitching machine

2. Durability of Stitching The strength of the stitch is vital for the functionality of PP woven bags. Machines designed specifically for this purpose ensure that the stitching can withstand various stresses, such as weight and impact during handling and transportation. Quality stitching prevents the bags from coming apart, which could lead to product loss and potential financial setbacks.

3. Versatility Modern PP woven bag stitching machines come equipped with various stitching options, allowing manufacturers to produce bags of different sizes and designs. This versatility enables companies to cater to diverse market needs, adapting quickly to changes in consumer demand or industry trends.

4. User-Friendly Technology With advancements in technology, current stitching machines are often equipped with user-friendly interfaces and automated features. These enhancements make it easier for operators to monitor and control the stitching process, reducing the likelihood of errors and improving overall productivity.

5. Cost-Effectiveness Investing in a PP woven bag stitching machine can lead to significant long-term savings. The initial investment in high-quality machinery is often offset by lower labor costs and reduced production time. Furthermore, the durability of the stitching minimizes the need for rework, ultimately contributing to a healthier bottom line.

Conclusion

As the demand for efficient and reliable packaging solutions continues to grow, the role of PP woven bag stitching machines in the manufacturing industry cannot be overstated. These machines not only improve the efficiency and quality of bag production but also contribute to overall operational success. As industries evolve and new challenges emerge, businesses that invest in state-of-the-art stitching technology will be better positioned to thrive in a competitive market. In summary, PP woven bag stitching machines are a vital component in the journey of turning raw materials into robust packaging solutions, ensuring that products reach consumers safely and efficiently.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025