Feb . 14, 2025 18:40

Back to list

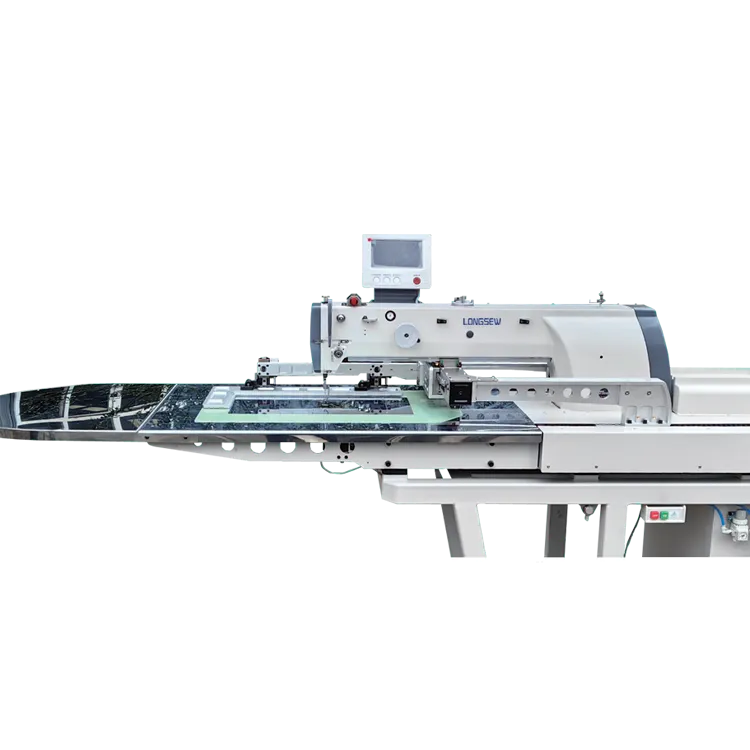

Fishing Net Hauling Rope Single Needle 3 Threads Overedging Sewing Machine 81500CZ

Navigating the complex world of industrial machinery can be a daunting task, especially when it comes to selecting the best equipment for specific needs such as pp woven bag sewing machines. Garnering expertise through hands-on experiences alongside authoritative insights can significantly influence decisions in procuring these machines. Here's a comprehensive exploration into the multifaceted domain of pp woven bag sewing machines, focusing on the unparalleled benefits and considerations essential for informed decision-making.

An authoritative perspective from seasoned manufacturers showcases how the right machine integrates seamlessly into existing production workflows, enhancing output without incurring additional labor costs. For businesses, an optimal machine will balance initial investment with long-term benefits, making it essential to prioritize machines with reliable warranties and support services. Trusted brands often provide comprehensive training sessions and certification courses aimed at maximizing efficiency and safety. Trustworthiness is another pivotal element when selecting machinery. Reputable suppliers should offer machines that comply with international safety standards and provide detailed documentation regarding maintenance and troubleshooting. Establishing a relationship with a dependable supplier ensures continual updates on best practices, new technologies, and upcoming industry trends, which can significantly benefit long-term operations. Furthermore, the implementation of quality pp woven bag sewing machines aligns with modern eco-conscious trends. A machine that minimizes fabric waste and exertion of resources can contribute significantly to reducing the carbon footprint, aligning with global sustainable practices and elevating a company's reputation in the market. Concluding with the cumulative benefits, investing in high-performance pp woven bag sewing machines equates to an investment in the future of packaging solutions. Precision, efficiency, and considerable returns on investment highlight the powerful impact these machines can have. With expert handling, authoritative insights, and a consciousness towards sustainable practices, businesses can not only enhance their operations but also position themselves as leaders in their respective industries. Trust in well-informed decisions paves the way for industry advancements and ultimate success.

An authoritative perspective from seasoned manufacturers showcases how the right machine integrates seamlessly into existing production workflows, enhancing output without incurring additional labor costs. For businesses, an optimal machine will balance initial investment with long-term benefits, making it essential to prioritize machines with reliable warranties and support services. Trusted brands often provide comprehensive training sessions and certification courses aimed at maximizing efficiency and safety. Trustworthiness is another pivotal element when selecting machinery. Reputable suppliers should offer machines that comply with international safety standards and provide detailed documentation regarding maintenance and troubleshooting. Establishing a relationship with a dependable supplier ensures continual updates on best practices, new technologies, and upcoming industry trends, which can significantly benefit long-term operations. Furthermore, the implementation of quality pp woven bag sewing machines aligns with modern eco-conscious trends. A machine that minimizes fabric waste and exertion of resources can contribute significantly to reducing the carbon footprint, aligning with global sustainable practices and elevating a company's reputation in the market. Concluding with the cumulative benefits, investing in high-performance pp woven bag sewing machines equates to an investment in the future of packaging solutions. Precision, efficiency, and considerable returns on investment highlight the powerful impact these machines can have. With expert handling, authoritative insights, and a consciousness towards sustainable practices, businesses can not only enhance their operations but also position themselves as leaders in their respective industries. Trust in well-informed decisions paves the way for industry advancements and ultimate success.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025