pp woven bag cutting sewing printing line machine

The Efficiency of the PP Woven Bag Cutting, Sewing, and Printing Line Machine

In the realm of modern manufacturing, efficiency and quality are paramount, especially when it comes to producing packaging materials. One of the most significant advancements in this sector is the development of the PP (Polypropylene) woven bag cutting, sewing, and printing line machine. This integrated system brings together multiple processes necessary for producing high-quality woven bags, making it an indispensable asset for manufacturers.

Understanding PP Woven Bags

PP woven bags are widely used in various industries due to their strength, durability, and versatility. They are commonly employed for packaging agricultural products, building materials, chemicals, and even food items. The process of creating these bags involves several steps weaving the polypropylene fabric, cutting it to size, sewing the edges, and printing labels or designs. Each step requires precision and efficiency to ensure a high-quality final product.

The Cutting Process

The first stage in the production of PP woven bags is the cutting process. Traditional methods of cutting can be labor-intensive and prone to errors. However, with the introduction of cutting machines specifically designed for this purpose, manufacturers can achieve greater precision and speed. These machines typically come equipped with advanced technology, such as automated cutting systems that can handle large rolls of fabric quickly and accurately. This efficiency not only reduces material waste but also significantly lowers production costs.

Sewing Technologies

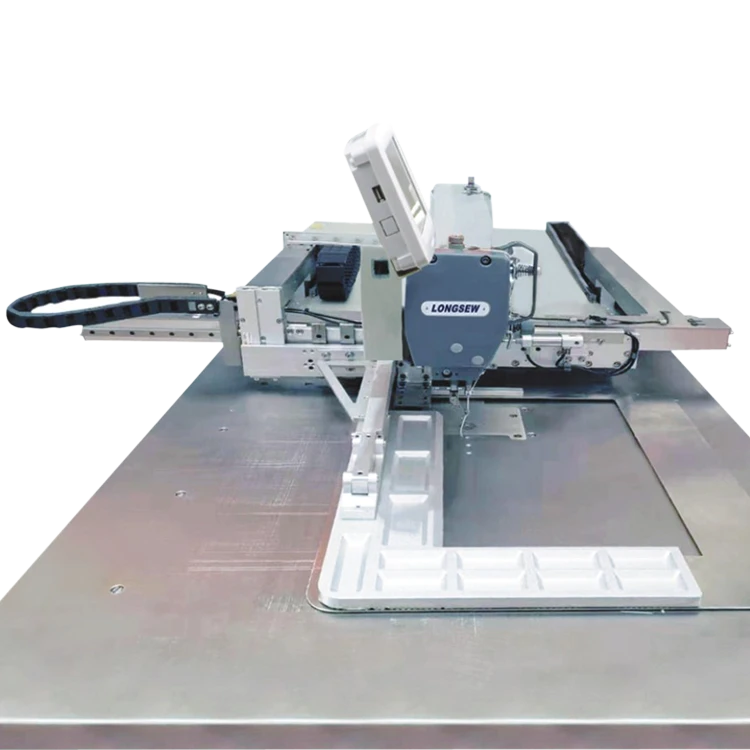

After the bags are cut to the desired dimensions, they must be sewn together. The sewing process is crucial because it determines the strength and durability of the bag. A reliable PP woven bag cutting, sewing, and printing line machine combines both the cutting and sewing phases to create a seamless workflow. Most modern sewing machines used in this context are designed to handle heavy-duty materials and offer various stitching options, ensuring that the bags can withstand the rigors of their intended use.

One of the notable innovations in sewing technology is the incorporation of automated sewing systems. These machines can adjust sewing patterns and tension based on the fabric's thickness, ensuring consistent quality across all products. Moreover, automated systems reduce the reliance on manual labor, allowing manufacturers to scale up production without compromising quality.

pp woven bag cutting sewing printing line machine

The Printing Process

Printing on PP woven bags is essential for branding and product identification. Traditional methods of printing can be cumbersome and require lengthy setup times. However, the integrated printing technology found in modern cutting and sewing line machines has transformed this aspect of production. These machines can print high-quality designs directly onto the bags, ensuring vibrant colors and sharp images.

Direct printing on PP material requires specialized inks that adhere well and remain durable through various handling and environmental conditions. Modern printing systems often incorporate UV-curing technologies that enhance ink durability and allow for faster drying times. This means that bags can move rapidly through the production line without delays, further improving overall efficiency.

Advantages of Integrated Systems

The integration of cutting, sewing, and printing processes into a single machine offers numerous benefits for manufacturers. Firstly, it streamlines operations, reducing the need for multiple machines and minimizing the space required on the factory floor. This not only lowers operational costs but also facilitates easier maintenance and management of machinery.

Secondly, an integrated line enhances quality control. When all processes are contained within a single system, it’s easier to monitor quality at each stage, ensuring that any defects are addressed immediately. This results in a higher quality end product, which is crucial in maintaining customer satisfaction and loyalty.

Conclusion

The PP woven bag cutting, sewing, and printing line machine represents a significant advancement in packaging manufacturing. By integrating key production processes into a single system, manufacturers can achieve unprecedented levels of efficiency and quality. As industries continue to evolve and the demand for sustainable and durable packaging solutions grows, the role of advanced machinery will undoubtedly become even more critical. Investing in such technology not only enhances productivity but also positions manufacturers favorably in a competitive market, paving the way for innovation and growth in the packaging sector.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025