PP woven bag cutting and sewing machine for efficient production line solutions

The Evolution and Efficiency of PP Woven Bag Cutting and Sewing Machines

In the world of manufacturing, efficiency and precision are two cornerstones driving productivity. Among the various types of machinery, the PP woven bag cutting and sewing machine stands out for its essential role in the production of versatile packaging solutions. Polypropylene (PP) woven bags are widely used across different industries due to their durability, lightweight nature, and cost-effectiveness. These machines have undergone significant technological advancements, making them crucial in the modern production line.

The Importance of PP Woven Bags

PP woven bags are favored for packaging agricultural products, construction materials, fertilizers, and various other goods. Their strong, tear-resistant properties ensure that the contents remain secure during transportation and storage. Additionally, their ability to be produced in various sizes and colors makes them appealing to manufacturers looking to enhance brand visibility. This has spurred a growing demand for efficient production methods, leading to the development of specialized cutting and sewing machines.

Cutting and Sewing Machines A Brief Overview

A PP woven bag cutting machine precisely cuts rolls of polypropylene fabric into flat bags or specific sizes required for different applications. This cutting process is vital, as any inaccuracies can lead to increased waste and higher production costs. Modern cutting machines are equipped with advanced technology such as computerized controls and sensors that ensure high precision and reduce material wastage.

The subsequent sewing process is carried out by sewing machines designed to handle the unique properties of PP woven materials. These machines are engineered to perform high-speed stitching while maintaining strong seam integrity, crucial for protecting the bag’s contents. The sewing process can involve various techniques, including single or double stitching, depending on the bag's end use and required strength.

Technological Advancements

The shift towards automation and smart technology in manufacturing has greatly influenced the design and functionality of PP woven bag cutting and sewing machines. For instance, modern machines often incorporate features such as

1. Computer Numerical Control (CNC) CNC technology allows for precise cutting and sewing, enabling manufacturers to achieve intricate designs and tailored dimensions. This level of automation reduces human error and enhances efficiency.

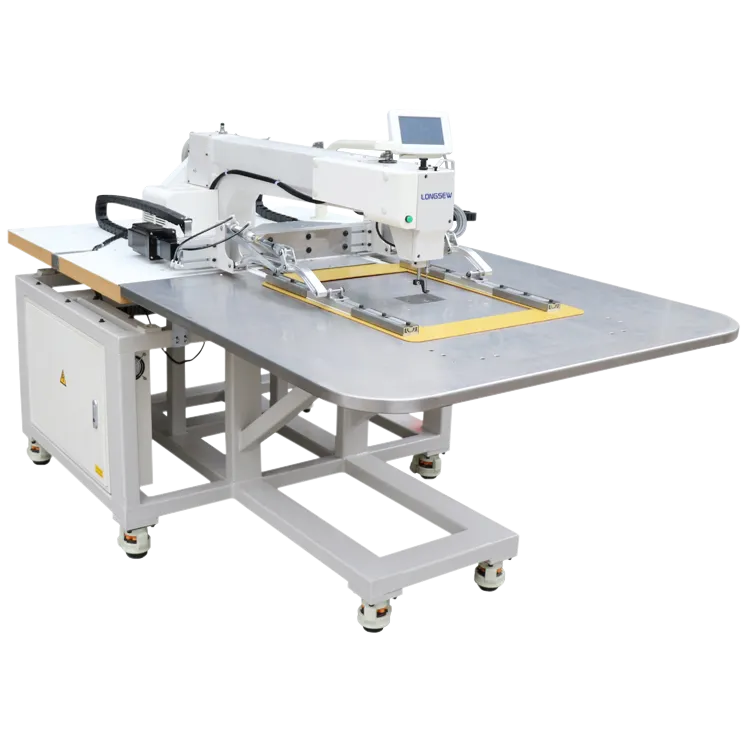

pp woven bag cutting sewing machine

3. Energy Efficiency With a growing focus on sustainability, many cutting and sewing machines are now designed to consume less energy while maintaining high performance. This not only reduces operational costs but also minimizes the environmental impact of production.

4. User-Friendly Interfaces Today's machines are often equipped with intuitive touchscreens and user-friendly controls, making it easier for operators to set parameters and swiftly adapt to production changes.

Advantages of Modern Machines

Investing in advanced PP woven bag cutting and sewing machines can provide manufacturers with numerous advantages

- Increased Production Speed High-speed cutting and sewing capabilities significantly reduce production cycles, allowing for greater output in less time.

- Consistency and Quality Automated machines deliver a consistent quality of product with fewer defects, which is essential for maintaining customer satisfaction.

- Reduced Labor Costs Automation reduces the need for extensive manual labor, allowing businesses to allocate their workforce to other value-added tasks.

- Flexibility Modern machines can be easily reconfigured to handle different bag sizes or styles, providing manufacturers with the flexibility to adapt to changing market demands.

Conclusion

The development of PP woven bag cutting and sewing machines represents a crucial step toward enhancing efficiency and productivity in the packaging industry. As technologies continue to evolve, these machines will likely become even more sophisticated, allowing manufacturers to meet the growing demands of diverse markets while maintaining high standards of quality and sustainability. The future of packaging looks promising, driven by innovation in machinery and the ever-expanding applications of PP woven bags.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025