PP Woven Bag Cutting and Sewing Equipment for Efficient Production

The Role of PP Woven Bag Cutting and Sewing Machines in Modern Manufacturing

In today's fast-paced manufacturing environment, the demand for efficient and durable packaging solutions has never been higher. Polypropylene (PP) woven bags have emerged as a preferred choice due to their strength, versatility, and eco-friendliness. The production of these bags requires specialized machinery, particularly PP woven bag cutting and sewing machines, which play a crucial role in ensuring quality and efficiency in the production process.

Understanding PP Woven Bags

PP woven bags are made from polypropylene, a thermoplastic polymer known for its high tensile strength and resistance to moisture. These bags are commonly used for packaging various products, including cement, fertilizers, grains, and animal feeds. Their woven structure allows for excellent breathability, making them suitable for products that require ventilation, such as agricultural goods. Additionally, they are lightweight, reducing transportation costs while offering significant load-bearing capacity.

The Importance of Cutting and Sewing Machines

The production process of PP woven bags begins with the raw material, which is woven into fabric. This fabric is then cut into specific sizes and sewn to create bags of various shapes and specifications. Cutting and sewing machines are integral to this process, as they ensure precision, speed, and consistency.

1. Cutting Machines These machines are responsible for accurately cutting the woven fabric into predetermined dimensions. Modern cutting machines utilize advanced technology, such as laser or automatic cutters, to minimize material waste and increase cutting speed. The precision of the cutting process directly influences the quality of the final product. A well-cut fabric ensures that seams align perfectly, preventing potential weaknesses that could lead to product failure.

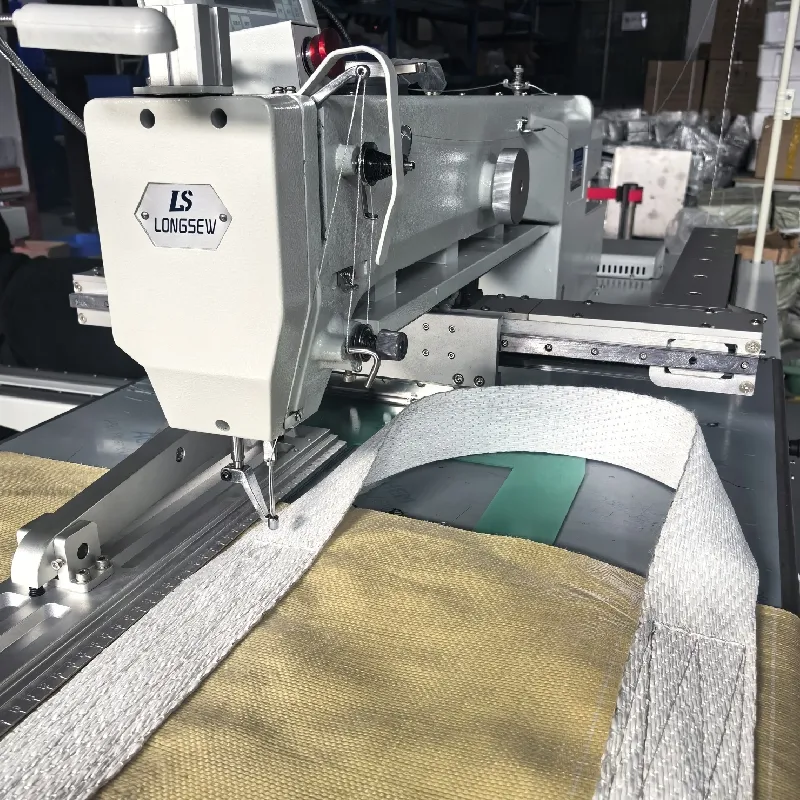

2. Sewing Machines After the fabric has been cut, sewing machines come into play. These machines are designed to stitch the edges of the woven fabric securely. Various types of sewing machines, such as sewing, overlock, and chain-stitch machines, can be used depending on the desired bag design and application. High-speed sewing machines equipped with multiple needles can significantly enhance production efficiency, allowing manufacturers to meet large order volumes and tight deadlines.

pp woven bag cutting and sewing machine

Advantages of Using Modern Machinery

The integration of modern cutting and sewing machines in the production of PP woven bags offers numerous advantages

- Increased Efficiency Automated machines can operate at high speeds, reducing the time taken to produce a batch of bags. This efficiency translates into higher output and lower labor costs.

- Enhanced Precision With advanced cutting technology, manufacturers can achieve greater accuracy in dimensions, ensuring that each bag meets the required specifications. This precision is essential for maintaining quality control and reducing the likelihood of defects.

- Versatility Modern machines can be easily adjusted to accommodate different bag designs, sizes, and printing requirements. This adaptability allows manufacturers to cater to a diverse clientele and respond to changing market demands.

- Sustainability Cutting and sewing machines designed for efficiency minimize material waste during production. Moreover, by producing reusable and recyclable PP woven bags, manufacturers contribute to environmental sustainability and meet increasingly stringent regulations regarding packaging waste.

Conclusion

The cutting and sewing of PP woven bags are critical processes in the manufacturing industry, and the machines used for these tasks must be both efficient and precise. As the demand for durable and sustainable packaging solutions continues to rise, investing in modern cutting and sewing technology is essential for manufacturers who aim to stay competitive in the market. By harnessing the capabilities of these machines, companies can improve productivity, ensure product quality, and contribute to environmental conservation. The future of packaging lies in the hands of innovative machinery that empowers manufacturers to deliver exceptional products while meeting the challenges of an evolving marketplace.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025