Jan . 12, 2025 09:39

Back to list

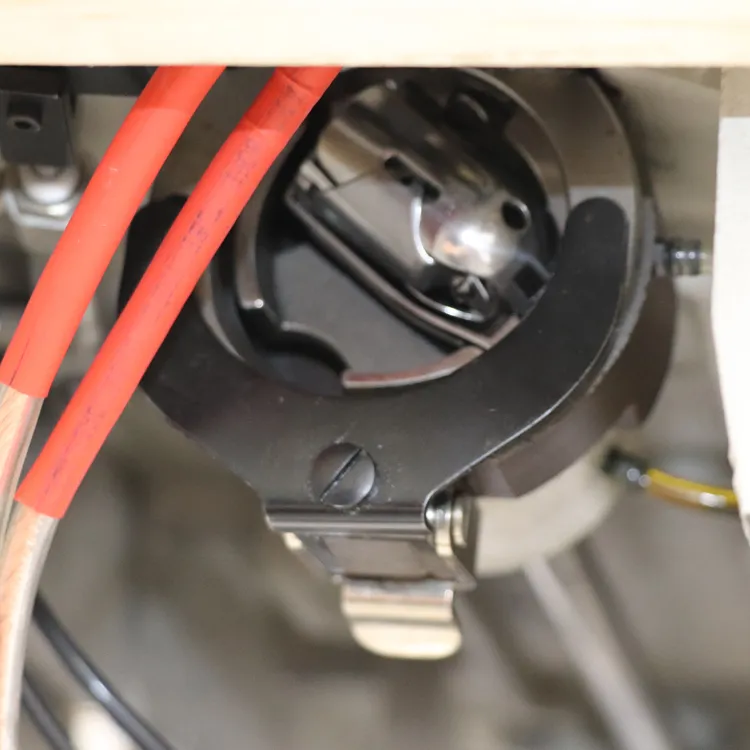

PP Woven Bag / Big Bag Single Needle 2 Threads Chainstitch Sewing Machine Head DN-2HS / DN-2LHS

Industrial double needle sewing machines are indispensable tools in modern garment manufacturing and upholstery industries. These machines stand out due to their exceptional ability to perform simultaneous stitching, enhancing both efficiency and precision in production processes.

Authoritativeness in the context of these machines can be attributed to leading manufacturers who have engineered innovative features designed to address common challenges faced in sewing operations. Brands like Juki, Brother, and Consew have ingrained technological advancements such as automatic thread trimming, programmable sewing patterns, and digital control interfaces. These features not only enhance machine operability but also serve as benchmarks in the industry, establishing their products as reputable choices for serious manufacturers. Trustworthiness is an inherent trait of industrial double needle sewing machines, as these units are constructed with robust materials designed to withstand continuous usage in demanding production environments. Testimonials and case studies from seasoned operators often highlight the reliability and durability of these machines, providing assurance to prospective buyers regarding their long-term value. Additionally, the availability of comprehensive customer support and service options from established brands further bolsters trust, ensuring that assistance is readily available should technical issues arise. Finally, choosing the right machine involves careful consideration of specific project needs, fabric types, and desired stitch patterns. Prospective buyers are encouraged to evaluate machines based on factors such as stitch length variability, ease of maintenance, and compatibility with additional accessories. The investment in a quality industrial double needle sewing machine promises substantial returns in terms of enhanced productivity, product quality, and operational efficiency, validating their quintessential role in the textile and upholstery sectors.

Authoritativeness in the context of these machines can be attributed to leading manufacturers who have engineered innovative features designed to address common challenges faced in sewing operations. Brands like Juki, Brother, and Consew have ingrained technological advancements such as automatic thread trimming, programmable sewing patterns, and digital control interfaces. These features not only enhance machine operability but also serve as benchmarks in the industry, establishing their products as reputable choices for serious manufacturers. Trustworthiness is an inherent trait of industrial double needle sewing machines, as these units are constructed with robust materials designed to withstand continuous usage in demanding production environments. Testimonials and case studies from seasoned operators often highlight the reliability and durability of these machines, providing assurance to prospective buyers regarding their long-term value. Additionally, the availability of comprehensive customer support and service options from established brands further bolsters trust, ensuring that assistance is readily available should technical issues arise. Finally, choosing the right machine involves careful consideration of specific project needs, fabric types, and desired stitch patterns. Prospective buyers are encouraged to evaluate machines based on factors such as stitch length variability, ease of maintenance, and compatibility with additional accessories. The investment in a quality industrial double needle sewing machine promises substantial returns in terms of enhanced productivity, product quality, and operational efficiency, validating their quintessential role in the textile and upholstery sectors.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025