Efficient Sewing Solutions for PP Bag Production and Stitching Machinery

Exploring the Advantages of PP Bag Stitching Machines

In today's rapidly evolving industrial landscape, packaging efficiency and durability have become imperative for manufacturers across various sectors. One crucial aspect of effective packaging is ensuring that products are securely contained, especially those transported in polypropylene (PP) bags. This is where PP bag stitching machines come into play, revolutionizing the packaging process with their efficiency and precision.

PP bags, made from polypropylene resin, are widely used for packaging agricultural products, grains, fertilizers, chemicals, and even construction materials due to their ability to withstand wear and tear. However, securing these bags properly is just as important as the bags themselves. PP bag stitching machines are specialized devices designed to stitch or seal the open ends of PP bags, ensuring that their contents remain intact during storage and transport.

Exploring the Advantages of PP Bag Stitching Machines

Moreover, the precision of stitching offered by these machines cannot be understated. Manual sealing methods often lead to inconsistencies and potential weaknesses in bag closures, which can result in product spoilage or spillage during transport. High-quality PP bag stitching machines ensure that each bag is sealed uniformly, eliminating the risk of loose or poorly sealed bags. This consistency not only enhances the integrity of the packaging but also minimizes waste and reduces the likelihood of costly product loss.

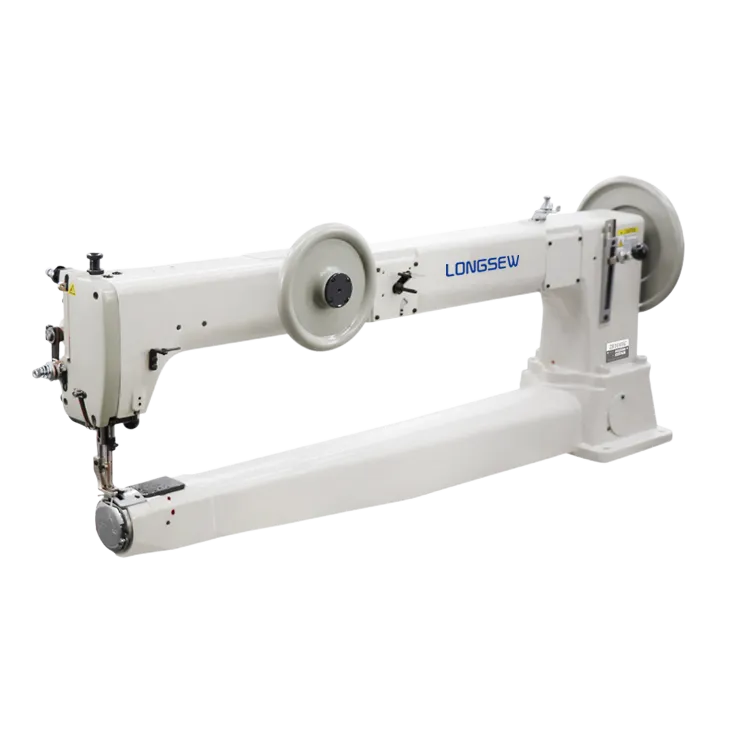

pp bag stitching machine

Durability is yet another compelling advantage of PP bag stitching machines. The stitching technology used in these machines creates strong seams that can withstand significant strain. This is particularly important in industries where bags are subject to stacking, handling, and transportation over long distances. A well-stitched PP bag can effectively handle heavy loads without the risk of breaking or tearing, providing manufacturers with peace of mind regarding their product's safety.

Furthermore, modern PP bag stitching machines are designed with operator convenience in mind. Many models come equipped with user-friendly interfaces, allowing operators to easily adjust settings to accommodate different bag sizes or stitching patterns. This adaptability is essential for businesses that handle a variety of products, enabling them to shift between different packaging requirements seamlessly.

Another notable aspect is the ongoing innovations in stitching technology. Manufacturers are continually improving these machines, incorporating features such as automatic feeding systems, computerized controls, and advanced monitoring systems that ensure optimal performance. These advancements not only boost efficiency but also enhance safety measures, reducing the risk of accidents during the packaging process.

In conclusion, PP bag stitching machines are essential tools for manufacturers looking to improve their packaging processes. Their speed, precision, durability, and user-friendly features offer a compelling case for businesses aiming to enhance efficiency and product safety. As industries continue to evolve, investing in advanced packaging solutions like PP bag stitching machines may well be a critical step toward achieving operational excellence and maintaining a competitive edge in the market. As the demand for reliable and efficient packaging solutions continues to grow, so too will the role of these machines in shaping the future of manufacturing and distribution.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025