pp bag sewing machine price

The Cost of PP Bag Sewing Machines An Overview

In recent years, the demand for polypropylene (PP) bags has surged due to their durability and environmental benefits compared to traditional plastic bags. This growing market has led to increased production needs, making efficient manufacturing processes essential. Central to these processes are PP bag sewing machines, which are specifically designed for stitching and assembling polypropylene bags. This article explores the various aspects influencing the prices of these machines.

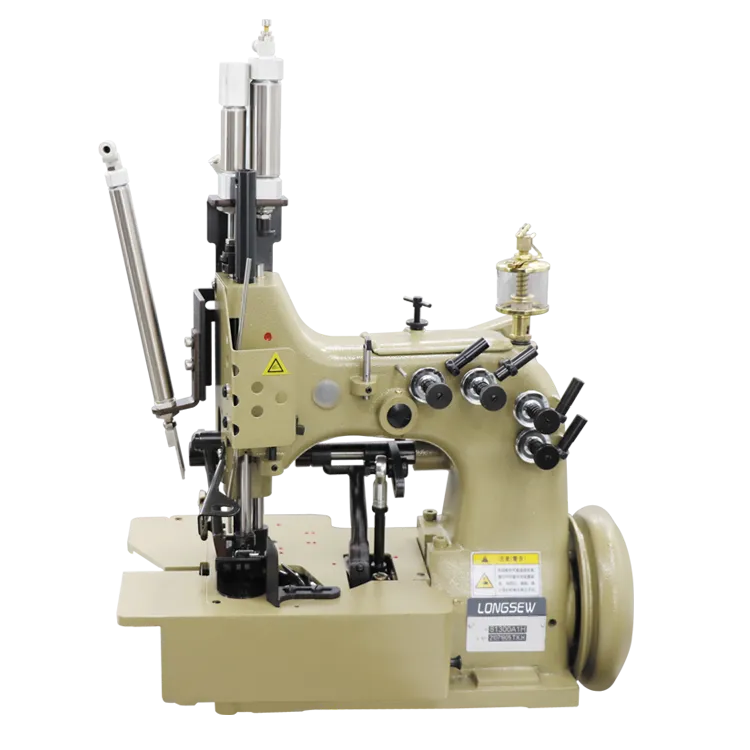

Understanding PP Bag Sewing Machines

PP bag sewing machines are engineered to handle heavy-duty fabrics, which are widely used in various industries for packaging purposes. These machines can accommodate different bag types, including open-mouth, bottom-sealed, and pinch-bottom bags. Advanced models may even offer features like automatic threading, speed control, and precise stitching to enhance productivity and reduce operational costs.

Factors Influencing Prices

The price of PP bag sewing machines can vary significantly based on several factors

1. Machine Type and Features The basic models with standard functionalities can start at a few hundred dollars. However, more advanced, high-speed sewing machines with automatic features or specialized functionalities can range from several thousand to tens of thousands of dollars. Businesses must assess their production needs to choose a machine that offers the best value for money.

pp bag sewing machine price

2. Brand and Manufacturer Renowned brands known for their quality and durability may command higher prices. However, investing in a reputable brand often pays off in the long run due to lower maintenance costs and better service support.

3. Material Quality and Construction Machines made from high-quality materials with robust construction are generally priced higher but tend to provide better performance and longevity. Manufacturers should consider the machine's lifespan and potential repair costs when evaluating the initial purchase price.

4. Technological Advancements As technology evolves, newer models with improved efficiency and capabilities are introduced. These machines often come with a premium price tag but can lead to significant savings in labor costs and higher output, making them a wise investment for growing businesses.

5. Location and Import Costs The price of sewing machines can also vary by region due to shipping costs, taxes, and tariffs. Local manufacturers may offer more competitive pricing, while imported machines might incur additional expenses that affect the final purchase price.

Conclusion

Investing in a PP bag sewing machine can significantly enhance production efficiency for businesses involved in bag manufacturing. While prices range widely based on several influencing factors, it is crucial for companies to carefully analyze their needs and budget. By understanding the aspects that contribute to the cost of these machines, businesses can make informed decisions that align with their operational goals and budgetary constraints. As the demand for sustainable packaging continues to rise, the right PP bag sewing machine may serve as a vital tool for manufacturers aiming to capitalize on this growing market.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025