Jan . 14, 2025 10:07

Back to list

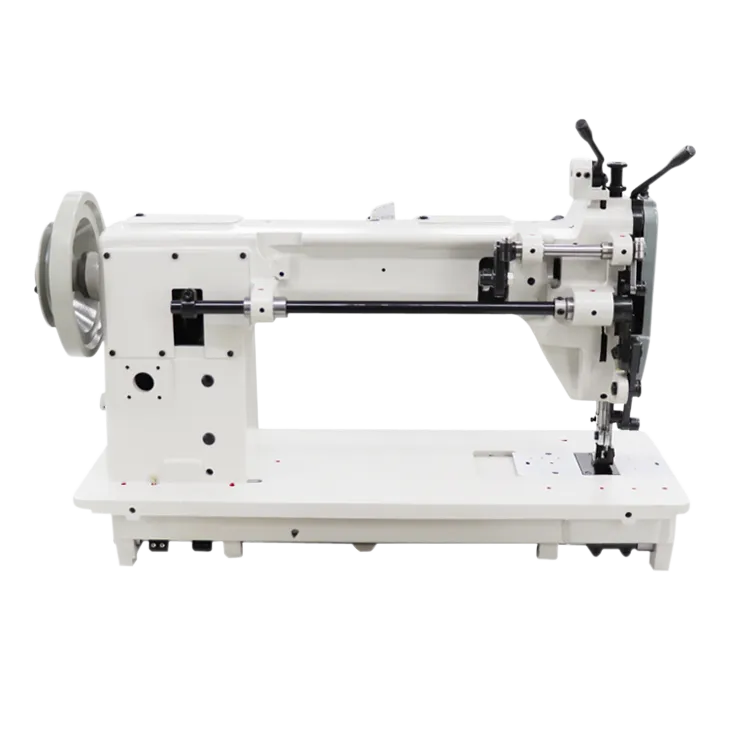

portable walking foot zigzag sewing machine

Double needle walking foot industrial sewing machines have become an indispensable asset for professional tailors and manufacturers striving for unparalleled precision and efficiency. With years of experience in the textile industry, I've witnessed firsthand the revolutionary enhancements these machines bring to the production line, drastically transforming fabric manipulation and sewing quality in specialized garment and upholstery applications.

Taking a deeper dive into its authoritativeness, the double needle walking foot industrial sewing machine is endorsed and trusted by industry veterans and leading manufacturers across the globe. Its adoption by reputable brands and factories is a testament to its reliability and performance. When investing in such a machine, businesses are assured of its robust construction and longevity. Typically built with heavy-duty metal components, these machines are engineered to withstand the rigors of continuous operation, proving their worth many times over in commercial environments. Trustworthiness is equally reflected in user feedback and testimonials. Users consistently highlight not just the machine's performance but also its role in expanding their capabilities. Whether it's intricate double-stitched lap seams, topstitching on heavy canvas, or decorative seams on leather furniture, the machine not only meets but exceeds expectations. Proper maintenance and adjustment are relatively straightforward, empowering operators with full control over their sewing projects and ensuring high-quality output without significant downtime. In conclusion, a double needle walking foot industrial sewing machine is more than just a tool; it is a transformative investment in precision, expertise, authority, and trust within the competitive landscape of garment and upholstery production. For professionals committed to excellence, integrating this machine into your production strategy can lead to superior products, enhanced client satisfaction, and a solidified reputation as a leader in quality craftsmanship.

Taking a deeper dive into its authoritativeness, the double needle walking foot industrial sewing machine is endorsed and trusted by industry veterans and leading manufacturers across the globe. Its adoption by reputable brands and factories is a testament to its reliability and performance. When investing in such a machine, businesses are assured of its robust construction and longevity. Typically built with heavy-duty metal components, these machines are engineered to withstand the rigors of continuous operation, proving their worth many times over in commercial environments. Trustworthiness is equally reflected in user feedback and testimonials. Users consistently highlight not just the machine's performance but also its role in expanding their capabilities. Whether it's intricate double-stitched lap seams, topstitching on heavy canvas, or decorative seams on leather furniture, the machine not only meets but exceeds expectations. Proper maintenance and adjustment are relatively straightforward, empowering operators with full control over their sewing projects and ensuring high-quality output without significant downtime. In conclusion, a double needle walking foot industrial sewing machine is more than just a tool; it is a transformative investment in precision, expertise, authority, and trust within the competitive landscape of garment and upholstery production. For professionals committed to excellence, integrating this machine into your production strategy can lead to superior products, enhanced client satisfaction, and a solidified reputation as a leader in quality craftsmanship.

Next:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025