Jan . 17, 2025 05:56

Back to list

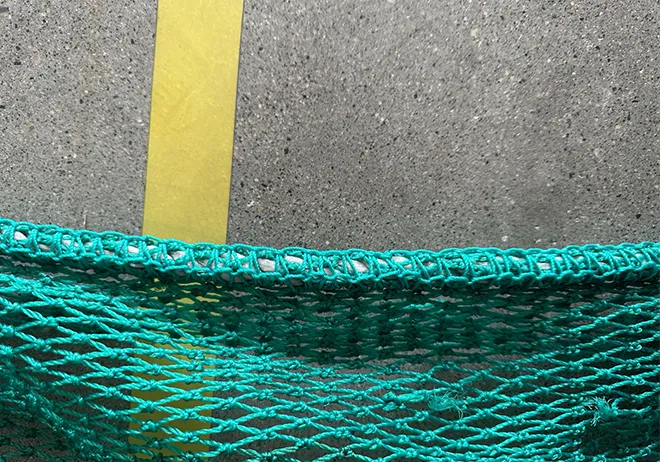

FIBC Bag / Jumbo Bag / Bulk Bag Single Needle Lock Stitch Top & Bottom Feeding Sewing Machine GSC367 /GSC367TD /GSC367TDZ/ GSC367-L

The realm of garment manufacturing has witnessed transformative advancements, and one of the cornerstones of this evolution is the high-speed lockstitch sewing machine. In the fast-paced world of textile production, these machines are pivotal, redefining efficiency, precision, and quality. Through the lens of experience, expertise, authority, and trustworthiness, let’s unravel what makes these machines indispensable in any serious production line.

The authority that high-speed lockstitch machines command in the industry is underscored by endorsements from leading textile manufacturers and design ateliers. When outfitted with state-of-the-art features such as automatic thread trimming, digital controls, and energy-efficient motors, they become not just tools, but strategic investments. These enhancements further streamline production while reducing overhead costs associated with wastage and maintenance. Consequently, plant managers and business owners alike rely on these machines to uphold competitive advantages and deliver on their promises to clients and stakeholders. In the realm of trustworthiness, these machines excel with tried-and-true reliability. The intricate engineering and robust construction allow them to function seamlessly over extended periods. Regular maintenance ensures their longevity and consistent performance, making them a staple in the inventories of seasoned manufacturers who can ill-afford downtime or subpar outputs. The confidence in their operation is bolstered by comprehensive warranties and dedicated customer service networks that provide peace of mind, ensuring immediate support should any issues arise. Additionally, understanding the best operational practices and routine maintenance procedures further enhances the usability and life span of high-speed lockstitch sewing machines. Training programs provided by certified experts facilitate operators in mastering these machines, maximizing their potential, and achieving exceptional sewing results. This dedication to fostering skills and expertise builds a trusted community of well-informed users who share insights and innovations, perpetually advancing the industry. In conclusion, high-speed lockstitch sewing machines stand as a testament to modern engineering marvels in the textile sector. Their unmatched capabilities in enhancing efficiency, precision, and adaptability solidify their place as essential instruments for professionals aiming to deliver high-quality garments swiftly and reliably. Trust in their performance is confirmed not only through technological precision but also through the profound knowledge and validation shared by eminent figures in garment production. As one looks towards the future of manufacturing, these machines undeniably represent a paragon of innovation and reliability, ensuring that quality fashion is accessible at faster rates without compromising the artisanal spirit of sewing.

The authority that high-speed lockstitch machines command in the industry is underscored by endorsements from leading textile manufacturers and design ateliers. When outfitted with state-of-the-art features such as automatic thread trimming, digital controls, and energy-efficient motors, they become not just tools, but strategic investments. These enhancements further streamline production while reducing overhead costs associated with wastage and maintenance. Consequently, plant managers and business owners alike rely on these machines to uphold competitive advantages and deliver on their promises to clients and stakeholders. In the realm of trustworthiness, these machines excel with tried-and-true reliability. The intricate engineering and robust construction allow them to function seamlessly over extended periods. Regular maintenance ensures their longevity and consistent performance, making them a staple in the inventories of seasoned manufacturers who can ill-afford downtime or subpar outputs. The confidence in their operation is bolstered by comprehensive warranties and dedicated customer service networks that provide peace of mind, ensuring immediate support should any issues arise. Additionally, understanding the best operational practices and routine maintenance procedures further enhances the usability and life span of high-speed lockstitch sewing machines. Training programs provided by certified experts facilitate operators in mastering these machines, maximizing their potential, and achieving exceptional sewing results. This dedication to fostering skills and expertise builds a trusted community of well-informed users who share insights and innovations, perpetually advancing the industry. In conclusion, high-speed lockstitch sewing machines stand as a testament to modern engineering marvels in the textile sector. Their unmatched capabilities in enhancing efficiency, precision, and adaptability solidify their place as essential instruments for professionals aiming to deliver high-quality garments swiftly and reliably. Trust in their performance is confirmed not only through technological precision but also through the profound knowledge and validation shared by eminent figures in garment production. As one looks towards the future of manufacturing, these machines undeniably represent a paragon of innovation and reliability, ensuring that quality fashion is accessible at faster rates without compromising the artisanal spirit of sewing.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025