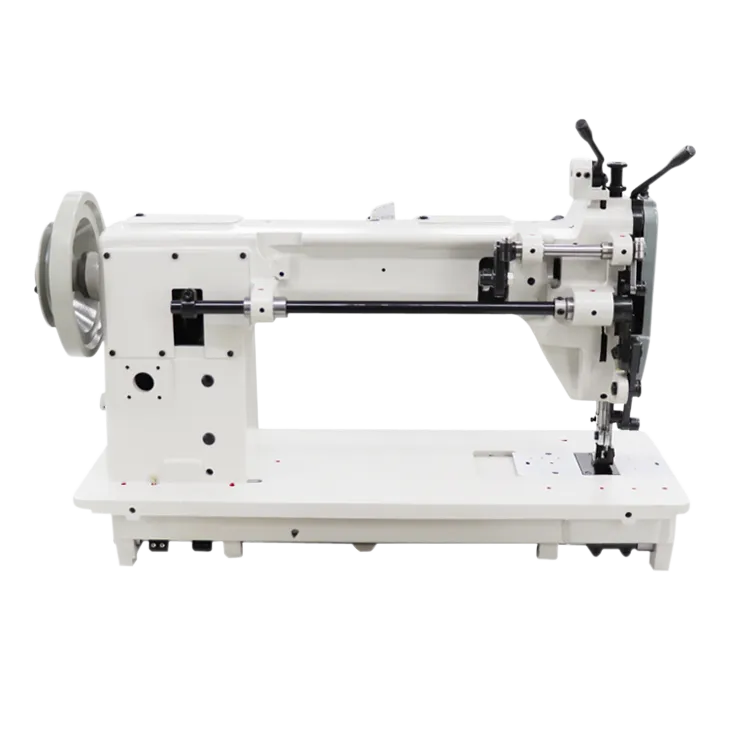

pattern stitching machine

Understanding the Importance of Pattern Stitching Machines in Textile Manufacturing

In the rapidly evolving world of textile manufacturing, pattern stitching machines play a pivotal role in enhancing the production process. These specialized sewing machines are designed to create intricate patterns on fabrics, adding aesthetic value and functionality to textile products. As the demand for customized and high-quality fabrics continues to rise, understanding the capabilities and advantages of pattern stitching machines becomes essential for manufacturers.

The Evolution of Pattern Stitching Technology

Pattern stitching machines have come a long way since their inception. Early versions were primarily manual, requiring skilled artisans to operate them. However, technological advancements have led to the development of automated and computerized pattern stitching machines. These modern machines not only increase efficiency but also offer a wider range of design possibilities. With the integration of computer-aided design (CAD) software, manufacturers can now create intricate patterns with precision, significantly reducing the time and effort involved in the design process.

Features of Modern Pattern Stitching Machines

Modern pattern stitching machines are equipped with various features that enhance their functionality and ease of use. For instance, many machines come with pre-programmed stitch patterns, allowing operators to select designs quickly and easily. Moreover, advanced machines often include adjustable stitch length and width settings, enabling the creation of customized patterns tailored to specific client requirements.

Another significant feature is the capacity for multi-needle stitching, which allows for complex designs to be executed in a single pass. This capability not only speeds up production but also ensures consistency in design, which is crucial for mass production.

Benefits of Using Pattern Stitching Machines

pattern stitching machine

The incorporation of pattern stitching machines into textile manufacturing offers numerous benefits. One of the primary advantages is the efficiency increase, enabling manufacturers to produce large quantities of patterned fabrics in a shorter amount of time. This increased productivity not only meets growing consumer demands but also enhances profitability.

Furthermore, pattern stitching machines contribute to the overall quality of textile products. The precision offered by these machines minimizes errors and ensures that patterns are consistent throughout the fabric. This aspect is especially important in competitive markets where consumers expect high-quality products.

The versatility of pattern stitching machines is another major benefit. They can be used on a variety of fabrics, including cotton, silk, and synthetic materials. This flexibility allows manufacturers to cater to different markets and respond quickly to changing fashion trends.

Future Trends in Pattern Stitching

As the textile industry continues to grow, the future of pattern stitching machines looks promising. Innovations in technology, such as artificial intelligence and machine learning, are expected to further enhance the capabilities of these machines. For instance, AI could aid in pattern recognition and optimization, leading to smarter and more efficient stitching processes.

Additionally, sustainable practices in textile manufacturing are gaining traction. Pattern stitching machines that utilize eco-friendly materials and processes are likely to become more popular. Manufacturers who adopt these sustainable practices will not only contribute to environmental conservation, but they will also appeal to a growing segment of environmentally-conscious consumers.

Conclusion

In conclusion, pattern stitching machines are an invaluable asset in the textile manufacturing industry. Their ability to produce intricate patterns with speed and precision makes them essential for meeting the demands of modern consumers. As technology continues to advance, the potential for pattern stitching machines to evolve and improve will undoubtedly shape the future of textile production. Manufacturers who leverage these machines will be better positioned to compete in the ever-changing market landscape, ensuring that they meet the needs of their customers while maintaining high standards of quality and efficiency.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025