Sewing Machine Patterns Designed Specifically for Footwear Creation and Repair

Exploring the World of Pattern Sewing Machines for Shoes

In the footwear industry, precision and quality are paramount. A significant advancement in this sector is the emergence of pattern sewing machines, specifically designed for shoe production. These machines have revolutionized the way shoes are made, enhancing efficiency while ensuring consistent quality in every stitch.

Pattern sewing machines specialize in sewing specific designs and patterns into various materials, enabling manufacturers to produce shoes that not only meet functional requirements but also artistic vision. These machines are equipped with advanced technology that allows for intricate designs, ensuring a perfect fit and aesthetic appeal. The ability to replicate complex patterns with precise accuracy is a game-changer in the competitive shoe market.

One of the key advantages of using a pattern sewing machine in shoe manufacturing is the speed at which production can occur. Traditional methods often rely on manual techniques that can be time-consuming and labor-intensive. By contrast, pattern sewing machines can handle multiple tasks simultaneously, drastically reducing production time. This is particularly important for brands that need to respond quickly to changing market trends and consumer demands.

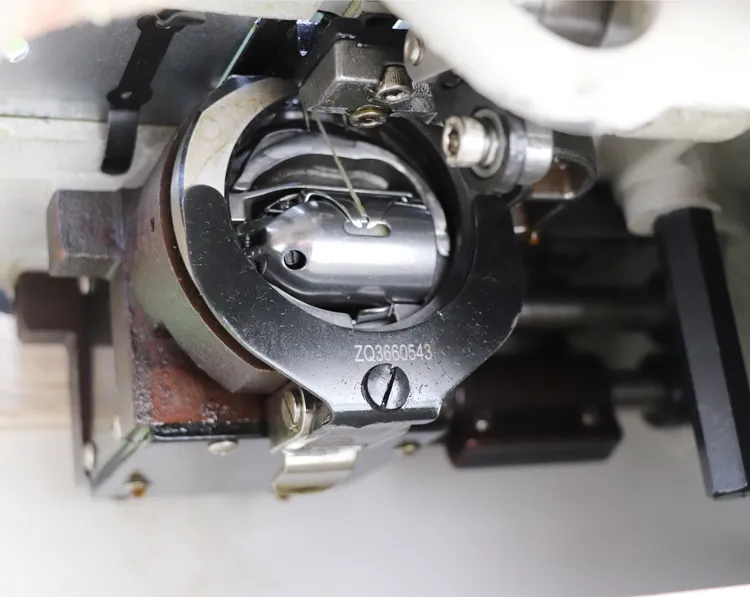

pattern sewing machine for shoes

Moreover, these machines can handle a wide range of materials, from leather to synthetic fabrics. This versatility enables manufacturers to experiment with different textures and finishes, catering to diverse consumer preferences. The adaptability of pattern sewing machines allows for innovative designs that push the boundaries of traditional footwear.

In addition to efficiency and versatility, pattern sewing machines provide superior quality control. With the help of computer software, these machines can be programmed to maintain specific stitch lengths and tension, ensuring uniformity throughout the production run. This consistency is crucial for ensuring that each pair of shoes meets the required standards for durability and comfort.

The integration of pattern sewing machines into the shoe production process aligns with the growing trend of sustainability in the fashion industry. By increasing efficiency and reducing waste, these machines contribute to more environmentally friendly manufacturing practices. The precision of pattern sewing also minimizes the amount of material that is lost during production, making the entire process more sustainable.

In conclusion, pattern sewing machines are an essential tool in modern shoe manufacturing. They offer numerous benefits, including enhanced efficiency, flexibility in design, and improved quality control, all of which are crucial in today's fast-paced market. As the footwear industry continues to evolve, the role of pattern sewing machines will undoubtedly become even more significant, paving the way for innovations that blend technology with creativity. As manufacturers increasingly adopt these advanced machines, consumers can expect to see not only a wider variety of shoe designs but also a commitment to quality and sustainability in the products they choose.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025