Feb . 13, 2025 13:17

Back to list

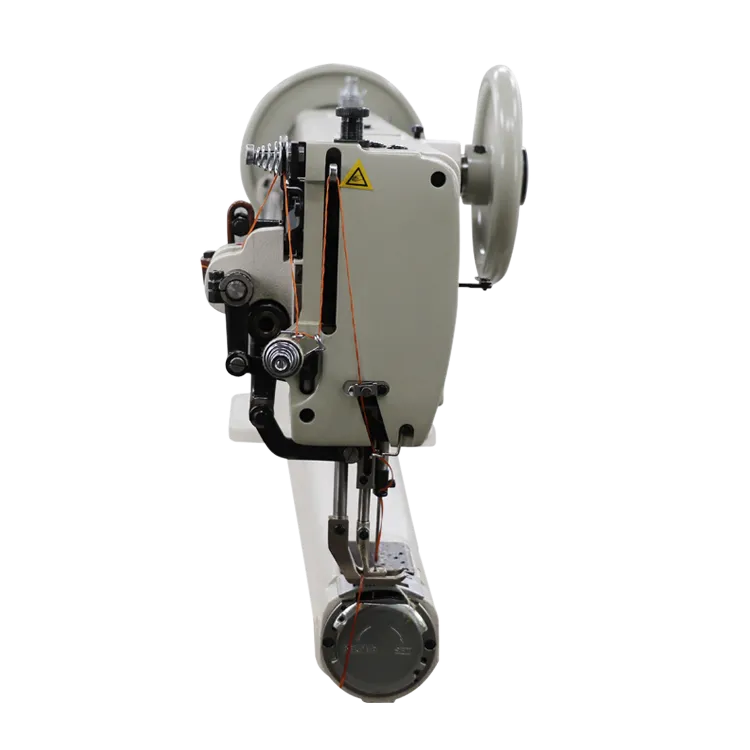

leather cylinder arm sewing machine

Navigating the niche realm of patch leather sewing machines demands a blend of technical understanding and hands-on experience to capitalize on their unique advantages. The specificity of these machines caters to both hobbyists and industry professionals who seek precision in leather crafting. Understanding the machinery's intricacies not only elevates craftsmanship but also builds a strong foundation in leatherwork's broader discipline.

Authority in this domain is further established by recognizing leading brands and models that dominate the market—a testament to their reliability and innovation. Brands like Adler, Singer, and Juki have engineered models specifically for patch leather sewing, each offering unique features like larger bobbin capacity, adjustable presser foot tension, and enhanced needle penetration power. Reviews and endorsements from respected leatherworking professionals strengthen the credibility of these machines, guiding potential buyers toward informed purchasing decisions. Trustworthiness in the context of patch leather sewing machines is reinforced through transparent demonstration of product capabilities and limitations. Engaging with platforms that offer community-driven reviews and insights can provide practical perspectives that traditional advertisements may overlook. This fosters a community-based trust where users share their unfiltered experiences, potentially highlighting lesser-known features and common pitfalls. In conclusion, the allure of patch leather sewing machines lies in their specialized utility, driving a blend of experiential learning and technical expertise. By delving into the intricate mechanics and acknowledging authority in the industry, users can harness these machines' full potential. Trust, formed through community engagement and credible endorsements, promotes a shared knowledge base that encourages continuous growth for both experienced leatherworkers and those newly embarking on this artistic journey. For anyone serious about their craft, embracing the nuances of a patch leather sewing machine promises to refine skills and elevate the standard of leather craftsmanship.

Authority in this domain is further established by recognizing leading brands and models that dominate the market—a testament to their reliability and innovation. Brands like Adler, Singer, and Juki have engineered models specifically for patch leather sewing, each offering unique features like larger bobbin capacity, adjustable presser foot tension, and enhanced needle penetration power. Reviews and endorsements from respected leatherworking professionals strengthen the credibility of these machines, guiding potential buyers toward informed purchasing decisions. Trustworthiness in the context of patch leather sewing machines is reinforced through transparent demonstration of product capabilities and limitations. Engaging with platforms that offer community-driven reviews and insights can provide practical perspectives that traditional advertisements may overlook. This fosters a community-based trust where users share their unfiltered experiences, potentially highlighting lesser-known features and common pitfalls. In conclusion, the allure of patch leather sewing machines lies in their specialized utility, driving a blend of experiential learning and technical expertise. By delving into the intricate mechanics and acknowledging authority in the industry, users can harness these machines' full potential. Trust, formed through community engagement and credible endorsements, promotes a shared knowledge base that encourages continuous growth for both experienced leatherworkers and those newly embarking on this artistic journey. For anyone serious about their craft, embracing the nuances of a patch leather sewing machine promises to refine skills and elevate the standard of leather craftsmanship.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025