Affordable Prices for Overlock Machine Motors in 2023

Understanding the Price Dynamics of Overlock Machine Motors

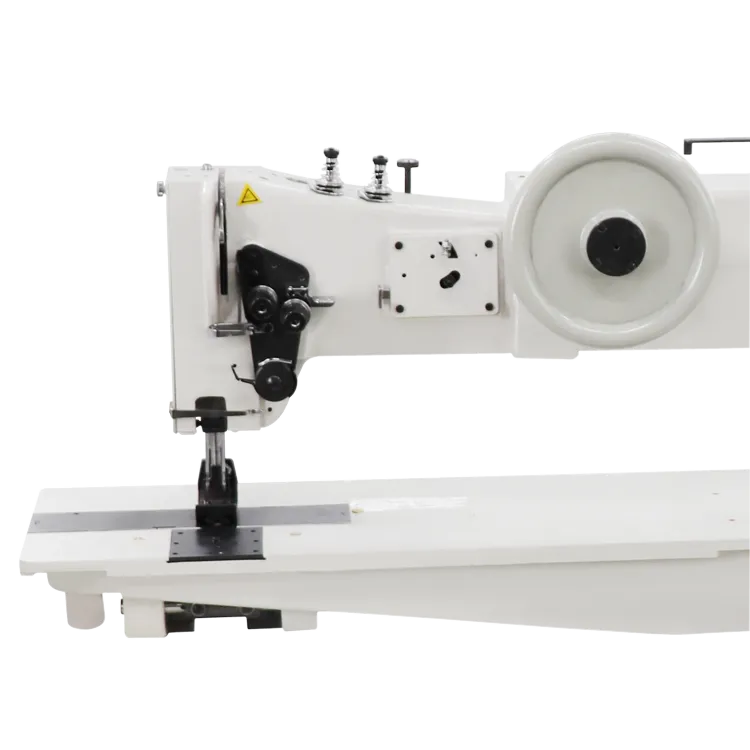

Overlock machines are vital pieces of equipment in the textile and garment industries. They are designed to stitch edges of fabrics together, preventing fraying and creating a professional finish. Central to the function of these machines is their motor, which determines speed, efficiency, and reliability. When considering the purchase or replacement of an overlock machine motor, one must take into account various factors that influence pricing in this specialized market.

Factors Influencing Overlock Machine Motor Prices

1. Type of Motor Overlock machine motors come in different types, including universal motors, stepper motors, and servo motors. Servo motors, known for their precision and energy efficiency, tend to be more expensive than conventional universal motors. The choice of motor directly impacts the price; therefore, understanding the specific needs of your operation is crucial.

2. Brand Reputation Well-established brands with a history of producing high-quality motors often charge a premium. These brands are known for their durability and reliability, which translates to lower maintenance costs and longer service life. Conversely, lesser-known brands may offer more competitively priced options, but they could compromise on quality and performance.

3. Horsepower Rating The horsepower rating of an overlock machine motor plays a significant role in its pricing. Motors with higher horsepower ratings generally cost more, as they provide greater power and are suitable for heavier workloads. It is essential to assess the workload requirements of your specific applications to choose the right motor without overspending.

4. Technological Features Modern overlock machine motors often come equipped with advanced technology, such as programmable settings, adjustable speeds, and connectivity features. These enhancements can significantly increase the motor’s price, but they also offer greater flexibility and efficiency in production. Investing in a technologically advanced motor can lead to better outputs and reduced operational costs.

overlock machine motor price

5. Power Consumption Energy-efficient motors may have a higher upfront cost but can lead to significant savings in energy bills over time. When evaluating prices, consider the long-term operational costs associated with running the motor. An energy-efficient motor may be a more economical choice in the long run.

6. Market Demand and Supply Like any other product, the pricing for overlock machine motors is also influenced by market demand and supply. During peak seasons, you might find prices trending upwards due to increased demand. Additionally, supply chain disruptions can affect availability and, consequently, pricing.

7. Manufacturer Location The geographical location of the manufacturer can influence prices due to shipping costs and tariffs. Motors manufactured in countries with lower production costs may be priced more competitively; however, it’s important to consider the quality and reliability of such products before making a purchase.

Conclusion

In conclusion, understanding the factors that influence the pricing of overlock machine motors can help businesses make informed purchasing decisions. While it might be tempting to opt for the cheapest option available, it's crucial to consider factors such as motor type, brand reputation, horsepower, technological features, energy efficiency, market dynamics, and the manufacturer’s location. By doing so, one can achieve a balance between cost and quality, ensuring optimal performance and longevity of the overlock sewing machines in use.

Investing time in research and comparison can yield significant benefits in terms of productivity and operational efficiency. As the garment industry continues to evolve, staying abreast of technological advancements in motor design and engineering will be vital in maintaining a competitive edge. Hence, investing in the right overlock machine motor is not just a matter of expense; it is an investment in the future of your business.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025