Mar . 06, 2025 12:02

Back to list

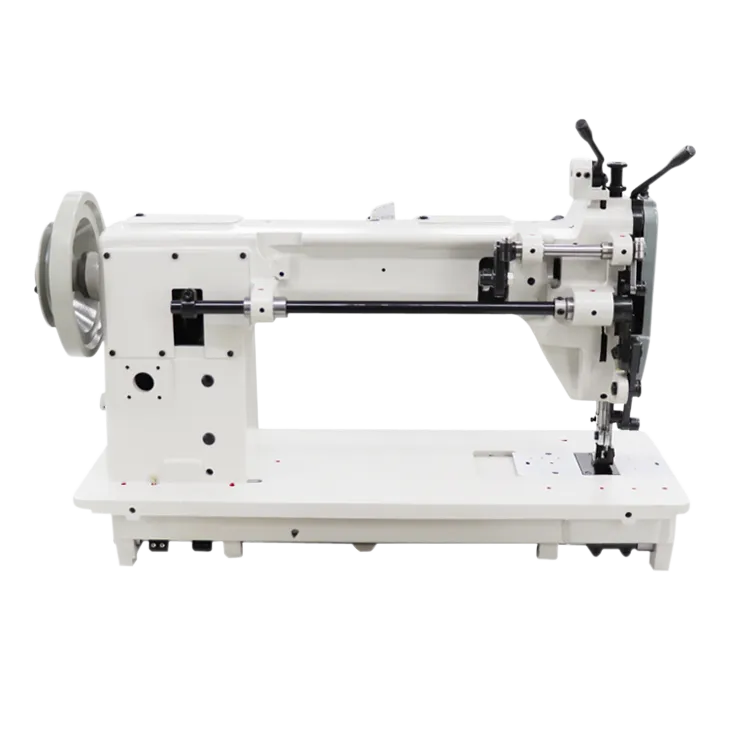

overlock and coverstitch machine

Overlock and coverstitch machines are integral tools in the arsenal of any serious home tailor or professional sewist, offering a level of finish and versatility that traditional sewing machines cannot match. To genuinely understand the power and functionality these machines offer, one must dive into the specifics of their operation, applications, and the quality of output they provide. This article will illuminate the unique capabilities of overlock and coverstitch machines, providing a comprehensive guide backed by expert insights and trusted experiences in the field of sewing technology.

Experience with coverstitch machines reveals a significant advantage in time-saving. Traditional methods of hemming with a regular sewing machine require multiple steps and stitches, which a coverstitch machine can accomplish in a single pass. This efficiency is essential for those producing garments on a larger scale or under tight deadlines. Furthermore, the ease of switching from one function to another ensures a seamless workflow, reducing the margin for error and thus boosting trustworthiness in garment production reliability. Critically, the choice between an overlock and coverstitch machine need not be mutually exclusive. Many professionals and experienced hobbyists advocate for owning both, appreciating each for its distinct yet complementary functionalities. For instance, the Brother 2340CV Coverstitch offers exceptional ease of threading and precision stitch formation, while the Juki MO-644D portable overlock machine is celebrated for its robust build and smooth operation. Both brands and models have carved out an authoritative position in the sewing community, often recommended by industry experts and enthusiasts alike. In terms of trustworthiness, selecting the right machine involves considering the brand’s reputation, customer reviews, and after-sale support, all critical aspects that anyone relying on these machines for professional use must carefully evaluate. Brands like Janome and Brother have consistently topped reliability charts due to their technological advancement and user-friendly design, ensuring a dependable sewing experience irrespective of the fabric type or garment complexity. Ultimately, both the overlock and coverstitch machines are invaluable complements to any sewing room, enhancing the creative process with specialized stitches and applications that amplify both the aesthetics and durability of the finished projects. Professionals and hobbyists alike cherish these machines not only for their technical prowess but also for the freedom they offer in exploring new sewing possibilities. The profound impact these machines have had on garment quality and production efficiency speaks volumes of their indispensability in modern sewing practices.

Experience with coverstitch machines reveals a significant advantage in time-saving. Traditional methods of hemming with a regular sewing machine require multiple steps and stitches, which a coverstitch machine can accomplish in a single pass. This efficiency is essential for those producing garments on a larger scale or under tight deadlines. Furthermore, the ease of switching from one function to another ensures a seamless workflow, reducing the margin for error and thus boosting trustworthiness in garment production reliability. Critically, the choice between an overlock and coverstitch machine need not be mutually exclusive. Many professionals and experienced hobbyists advocate for owning both, appreciating each for its distinct yet complementary functionalities. For instance, the Brother 2340CV Coverstitch offers exceptional ease of threading and precision stitch formation, while the Juki MO-644D portable overlock machine is celebrated for its robust build and smooth operation. Both brands and models have carved out an authoritative position in the sewing community, often recommended by industry experts and enthusiasts alike. In terms of trustworthiness, selecting the right machine involves considering the brand’s reputation, customer reviews, and after-sale support, all critical aspects that anyone relying on these machines for professional use must carefully evaluate. Brands like Janome and Brother have consistently topped reliability charts due to their technological advancement and user-friendly design, ensuring a dependable sewing experience irrespective of the fabric type or garment complexity. Ultimately, both the overlock and coverstitch machines are invaluable complements to any sewing room, enhancing the creative process with specialized stitches and applications that amplify both the aesthetics and durability of the finished projects. Professionals and hobbyists alike cherish these machines not only for their technical prowess but also for the freedom they offer in exploring new sewing possibilities. The profound impact these machines have had on garment quality and production efficiency speaks volumes of their indispensability in modern sewing practices.

Previous:

Next:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025