Leather Sewing Machine Solutions for Efficient and Quality Stitching Techniques

The Evolution of Machines for Leather Sewing

The art of leather crafting has a storied history, from ancient civilizations using rudimentary tools to modern artisans relying on advanced technology. One of the critical advancements in this domain has been the development of machines for leather sewing. These machines have revolutionized the way leather goods are manufactured, making the process faster, more efficient, and increasingly precise.

Historically, leather was sewn by hand, a meticulous process that required significant skill and patience. Artisans would utilize needles and thread, often spending hours on a single item. This traditional craftsmanship, while beautiful and authentic, was labor-intensive and limited in scalability. With the rise of the Industrial Revolution, the need for efficiency pushed boundaries and encouraged innovations. The introduction of sewing machines marked a significant turning point, providing artisans and manufacturers with new means to craft leather goods.

The Evolution of Machines for Leather Sewing

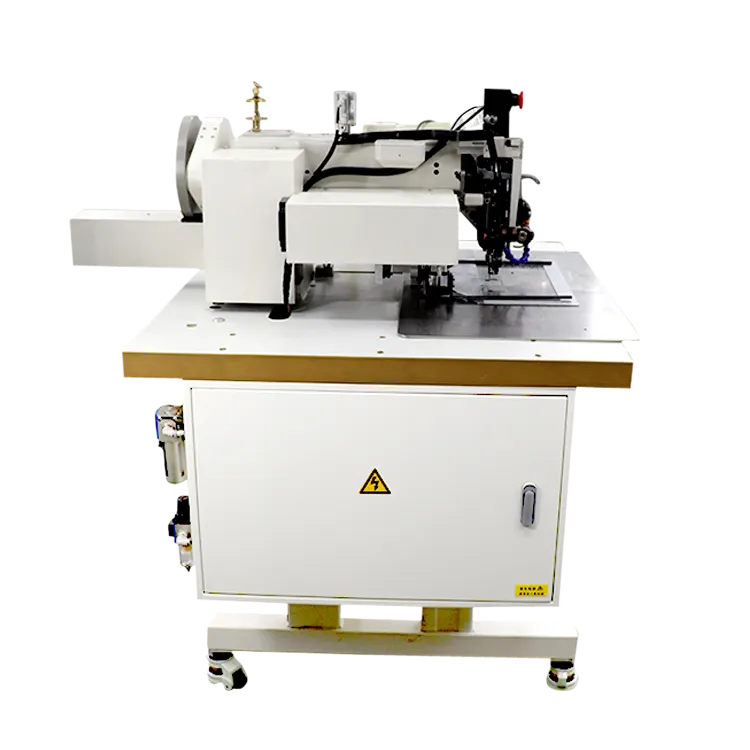

Today, there are several types of machines specifically built for leather sewing. Walking foot machines, for instance, are designed to feed leather smoothly through the machine, ensuring even stitching and minimizing the risk of material slipping. Heavy-duty machines are ideal for thick leather projects, while industrial models are built for high-volume production, allowing businesses to meet market demands efficiently. Moreover, computerized sewing machines have entered the scene, offering advanced features such as automatic thread trimming and programmable stitching patterns.

machine for leather sewing

The evolution of technology has not only improved efficiency but also enhanced precision in leather sewing. Automated cutting machines and laser cutters allow for intricate designs and patterns, while computerized sewing machines ensure that each stitch is perfectly placed. This level of precision was nearly impossible to achieve with manual methods, which increases the overall quality of leather products.

The environmental impact of leather production is also a growing concern. Modern machines are being designed with sustainability in mind, reducing waste during the cutting and sewing process. Furthermore, manufacturers are exploring eco-friendly alternatives to traditional leather, producing machines that can handle synthetic materials without compromising on quality.

As we look to the future, the integration of advanced technology such as artificial intelligence and machine learning into leather sewing machines is on the horizon. These innovations promise to further streamline the process, allowing for real-time adjustments and enhanced productivity. The adaptability of machines for leather sewing will continue to evolve, catering to both traditional artisans and contemporary manufacturers.

In conclusion, the journey of leather sewing machines from simple tools to sophisticated technological marvels illustrates the dynamic interplay between tradition and innovation. As the industry continues to evolve, these machines will remain at the forefront, enabling artisans and manufacturers to create beautiful, high-quality leather goods that honor both craft and contemporary demands.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025