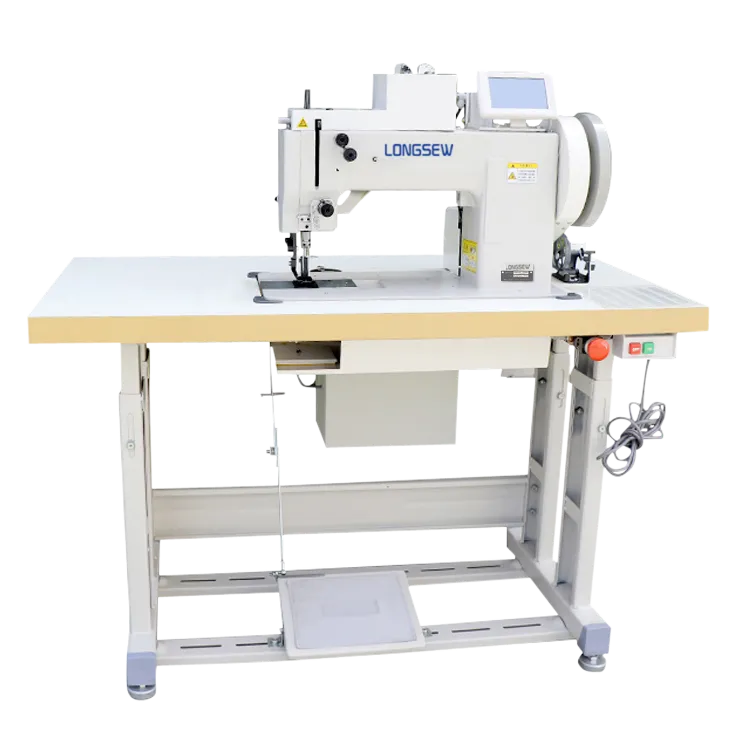

machine for leather sewing

The Evolution and Importance of Leather Sewing Machines

Leather has been a prized material throughout history, known for its durability and versatility. From luxury handbags to sturdy boots, leather products have established themselves as essential items in our daily lives. As the demand for leather goods has grown, so too has the technology behind their production. One of the most significant advancements in this realm is the development of leather sewing machines. These machines have revolutionized the way leather is crafted, combining efficiency with precision to produce high-quality goods.

The history of leather sewing machines can be traced back to the Industrial Revolution when innovations in machinery began to alter the landscape of manufacturing. Before the advent of these machines, leather goods were entirely hand-stitched, a process that was labor-intensive and often inconsistent in quality. The introduction of sewing machines designed specifically for leather work marked a significant turning point in the industry. These machines enabled artisans to stitch material faster and more reliably, paving the way for mass production while maintaining the craftsmanship that luxury leather goods require.

The Evolution and Importance of Leather Sewing Machines

One of the key features of modern leather sewing machines is their ability to handle multiple layers of leather without compromising the integrity of the stitch. The power of these machines allows them to penetrate tough materials smoothly, ensuring a consistent stitch length that is crucial for both structural strength and aesthetic quality. With adjustable tension settings and stitching speeds, leatherworkers can customize their machines to suit the specific requirements of their projects, further enhancing the quality of the finished product.

machine for leather sewing

Moreover, the use of leather sewing machines has expanded opportunities for creativity within the industry. Designers can experiment with various techniques, including decorative stitching, embossing, and attaching multiple leather pieces in complex configurations. This greater level of creative freedom leads to distinctive products that stand out in a competitive marketplace. In a world increasingly focused on individuality and customization, the role of innovative sewing machines cannot be overstated.

In addition to their technical advancements, many of today’s leather sewing machines prioritize user-friendly designs. Features such as automatic threading, digital displays, and built-in tutorials lower the learning curve for new users, making leatherwork accessible to a broader audience. As a result, more artisans and hobbyists can partake in this rewarding craft, leading to a resurgence of interest in leather goods and the skills required to create them.

The importance of leather sewing machines extends beyond mere production; they symbolize a blend of tradition and technology. While the process incorporates modern engineering, the craftsmanship remains deeply rooted in time-honored practices. Each piece of leather tells a story, and the meticulous work of sewing it together serves as a bridge between the past and the present.

In conclusion, leather sewing machines are indispensable tools in the leather goods industry. They enhance production efficiency, allow for creative exploration, and uphold the standard of quality that consumers expect. As technology continues to advance, so too will the possibilities for leather artisans who strive to innovate while honoring the rich heritage of their craft. The legacy of leather sewing machines is one of progress, creativity, and the enduring appeal of finely crafted leather products.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025