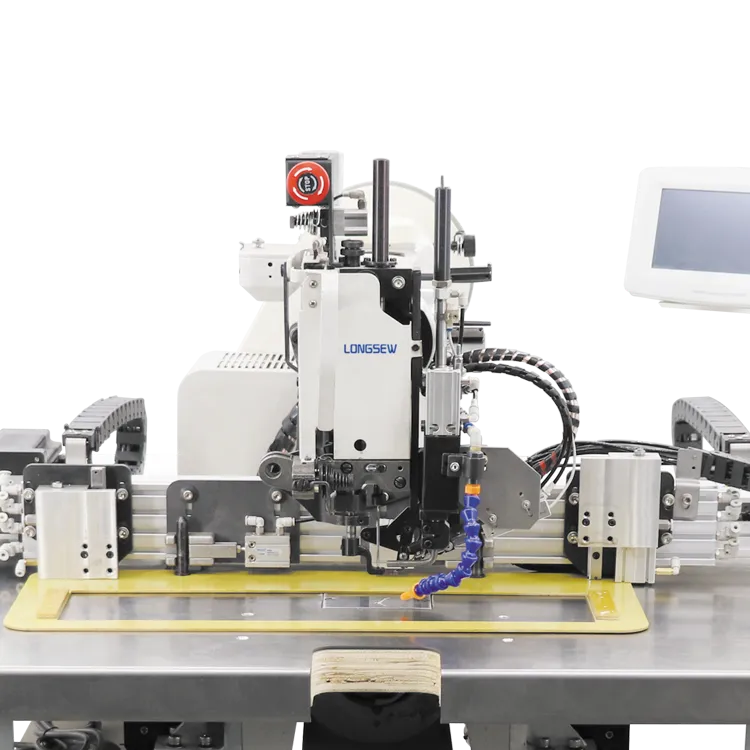

long arm sail making machine

The Long Arm Sail Making Machine Revolutionizing Sail Production

In the world of sailing, the quality and craftsmanship of sails play a critical role in determining a vessel's performance. Traditionally, the process of making sails has been labor-intensive, requiring skillful artisans to stitch together various fabric components. However, with advancements in technology, the long arm sail making machine has emerged as a revolutionary tool that significantly streamlines this process.

The long arm sail making machine is specifically designed to handle large pieces of fabric, allowing sail makers to create bigger and more complex sails with greater efficiency. One of its most notable features is the extended arm, which enables operators to work on larger materials without the need for constant repositioning. This capability is particularly advantageous when working with wide panels of sailcloth, which can often be cumbersome to maneuver manually.

A key advantage of the long arm sail making machine is its enhanced precision. Unlike manual stitching, which can result in inconsistencies due to human error, these machines are engineered for accuracy. With programmable settings and automated stitching patterns, sail makers can achieve uniformity across all seams and edges. This precision not only improves the overall aesthetics of the sail but also enhances its performance by ensuring that all components are securely and evenly stitched, minimizing the risk of damage during use.

long arm sail making machine

Moreover, the long arm sail making machine is designed for versatility. It can be used to create different types of sails, including mainsails, jib sails, and spinnakers, among others. Each sail type has specific design requirements, and the long arm machine can easily adapt to these needs. This flexibility allows sail makers to expand their offerings and cater to a broader range of customers, from recreational sailors to professional racing teams.

Another significant benefit of utilizing such a machine is the reduction in production time. By automating much of the sewing process, sail makers can significantly cut down on labor hours, allowing them to produce more sails in a shorter amount of time. This efficiency not only boosts productivity but also reduces operational costs, making it economically viable for sail makers to invest in high-quality materials and innovative designs.

Lastly, the long arm sail making machine contributes to a more sustainable approach to sail production. With precision cutting and stitching, there is less fabric waste generated compared to traditional methods. This attention to sustainability aligns with the growing awareness within the sailing community about the importance of protecting marine environments and resources.

In conclusion, the long arm sail making machine is transforming the sail making industry. By enhancing precision, versatility, efficiency, and sustainability, this technology empowers sail makers to meet the increasing demands of modern sailing enthusiasts. As the technology continues to evolve, we can expect further innovations that will keep pushing the boundaries of what is possible in sail production, ultimately leading to better sailing experiences for all.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025