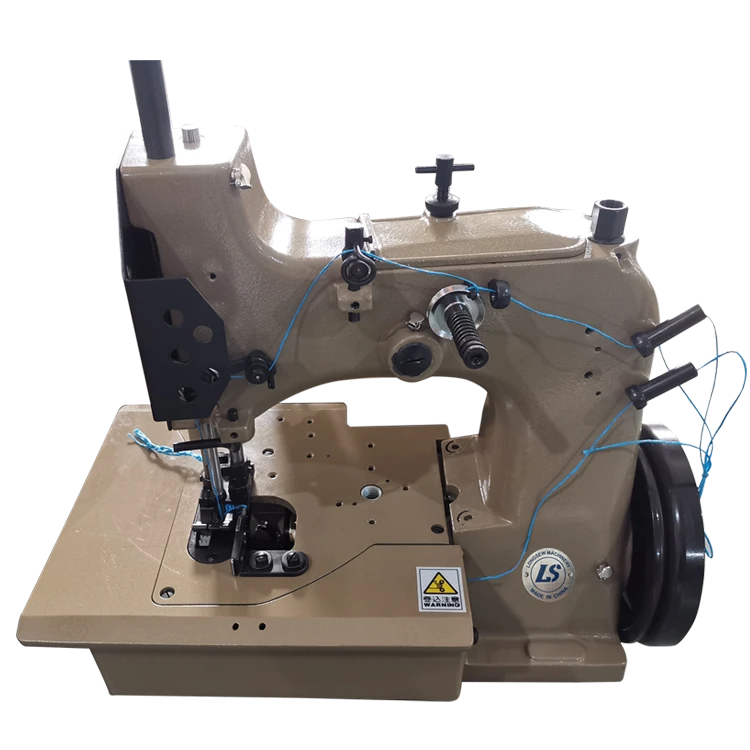

lock stitch machine

The Lock Stitch Machine Revolutionizing Textile Manufacturing

The lock stitch machine has been a pivotal innovation in the textile manufacturing industry, significantly transforming the way fabrics are sewn together. Originating in the mid-19th century, this sewing machine design has become essential in garment production, offering durability and efficiency in stitching.

At its core, the lock stitch machine operates on an ingenious mechanism involving a needle and a bobbin. The needle carries the upper thread downward through a fabric layer while simultaneously picking up the lower thread from the bobbin. This interlocking of threads creates strong, secure seams that are essential for the longevity of garments. The lock stitch is particularly favored for its ability to produce neat stitches with minimal thread tension, making it ideal for a wide variety of fabrics ranging from cotton to synthetic blends.

One of the primary advantages of the lock stitch machine lies in its versatility

. It can be used for various sewing techniques, including straight stitching, zigzag stitching, and even decorative stitching, making it invaluable for manufacturers. The machine's adaptability allows it to handle both light and heavy materials, ensuring that it can meet the demands of diverse production requirements. This versatility extends beyond clothing; it's also used in the production of upholstery, accessories, and industrial fabrics.lock stitch machine

Moreover, advancements in technology have continually evolved the design and functionality of lock stitch machines. Modern machines are equipped with computerized systems that can automatically adjust tension and stitch length, providing greater precision and reducing waste. These innovations enhance productivity, allowing manufacturers to increase output while maintaining quality. Additionally, features like automatic thread cutting and programmable sewing patterns help streamline the sewing process, demonstrating how technology continues to shape the manufacturing landscape.

In terms of sustainability, the lock stitch machine also plays a crucial role. With growing concerns about environmental impact, manufacturers are looking for ways to reduce waste and improve efficiency. The high durability of lock stitches contributes to longer-lasting garments, which can mitigate the fast fashion phenomenon where clothes are often disposed of after a few uses. By producing stronger seams, lock stitch machines contribute to the creation of sustainable products that are built to last.

Training and skill development are also essential components of operating a lock stitch machine effectively. While modern machines may come with user-friendly features, a deep understanding of sewing techniques and machine maintenance is critical for achieving the best results. Many vocational institutions and training centers now offer courses specifically focusing on sewing machinery, enabling aspiring seamstresses and tailors to master the lock stitch technique.

In conclusion, the lock stitch machine remains a cornerstone of the textile industry, combining functionality, durability, and adaptability. Its ability to produce strong, reliable seams has made it indispensable in garment manufacturing and beyond. As technological advancements continue to emerge, the lock stitch machine is set to evolve further, embracing sustainable practices while ensuring that quality remains at the forefront of textile production. The evolution of this machine embodies the spirit of innovation and craftsmanship that drives the fashion industry forward, ensuring that as it progresses, it remains rooted in the foundations laid down by its historic predecessors. Whether in a small tailoring shop or a large manufacturing facility, the lock stitch machine continues to be a testament to the art and science of sewing.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025