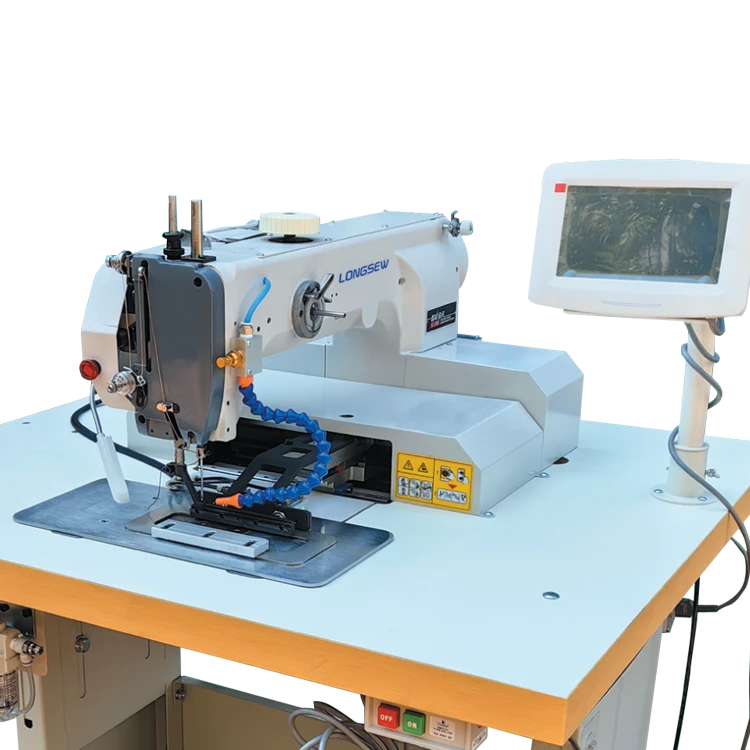

leather manual sewing machine

The Art of Manual Leather Sewing Machines

In the realm of leathercraft, manual sewing machines represent a timeless skill and craftsmanship that has transcended generations. These machines, often revered by artisans and craft enthusiasts alike, offer unparalleled control and precision, making them a favorite for creating durable and aesthetically pleasing leather goods.

Understanding Manual Leather Sewing Machines

A manual leather sewing machine operates without the complexities of modern electronics, relying instead on the operator's skill and the machine's mechanical parts to sew through tough leather materials. Built with robust materials, these machines are designed to handle the density and thickness of leather, which can vary greatly from one project to another.

Key components of a manual leather sewing machine include the needle, bobbin, presser foot, and tension settings. The needle is crucial for penetrating the leather, and specialty needles designed specifically for leatherwork are commonly used to prevent snagging or tearing. The presser foot provides the necessary grip to guide the leather through the machine seamlessly while maintaining an even stitch, and the tension settings allow the operator to adjust the thread tightness, which is vital for achieving a professional finish.

The Advantages of Manual Sewing

One of the primary advantages of using a manual sewing machine for leatherwork is the level of control it affords the artisan. Unlike electric machines, which may operate at high speeds, a manual machine encourages a slower, more deliberate pace. This deliberate sewing allows for greater attention to detail, essential when working with premium leathers where precision is paramount.

Additionally, manual machines often have fewer moving parts than their electric counterparts, which can translate to higher reliability and lower maintenance needs. This simplicity is an attractive feature for those who appreciate traditional craftsmanship or those just starting their journey in leatherwork.

Another significant advantage is the cost-effectiveness. Manual sewing machines are generally less expensive than their electrical counterparts. For hobbyists or small businesses looking to minimize startup costs, this is a major consideration.

leather manual sewing machine

Techniques and Tips

Successful leather sewing with a manual machine involves mastering various techniques. Firstly, before starting any project, it is essential to select the appropriate needle and thread. Heavy-duty polyester or nylon threads are preferred for leather projects due to their strength and durability.

When setting up the machine, ensure the stitch length is adjusted appropriately for your leather weight. A longer stitch (about 4-6 mm) is advisable for thicker leather, as it allows for better penetration without compromising the integrity of the material.

An essential skill to develop is guiding the leather piece through the machine smoothly. The tension between the presser foot and the feed dogs should be optimal; too tight may cause the leather to bunch, while too loose can result in uneven stitching.

Moreover, utilizing tools such as leather straps, clamps, and edge guides can help maintain straight and even lines, contributing to professional-looking results. Practicing on scrap pieces before moving to your final project is also a vital step; this allows you to refine your technique without risking your material.

The Future of Manual Leatherworking

As the world leans increasingly towards automation and technology, the art of manual leather sewing offers a refreshing contrast. The tactile experience of working with leather, feeling the texture, and appreciating the transformation from raw material to crafted piece is irreplaceable.

The revival of interest in handmade goods and sustainable practices has also led to a renaissance in manual leatherworking. Consumers are increasingly valuing the stories behind the products they purchase, often preferring artisanship that emphasizes quality, durability, and originality over mass production.

In conclusion, manual leather sewing machines are not just tools; they are instruments of creativity that connect the artisan to their craft. By embracing the techniques and traditions of manual leather sewing, artisans can continue to create beautiful, durable pieces that stand the test of time. Whether you're a seasoned professional or a novice eager to learn, investing time in mastering a manual leather sewing machine can be a rewarding and fulfilling endeavor that celebrates the rich heritage of leathercraft.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025