Leather Foot Attachment for Sewing Machines to Enhance Stitching Precision

Exploring Leather Feet for Sewing Machines A Comprehensive Guide

When it comes to sewing leather, having the right tools can make a significant difference in the quality of your work. One essential component often overlooked by both beginners and seasoned professionals alike is the leather foot for sewing machines. This specialized presser foot is designed to handle the unique characteristics of leather, ensuring smooth operation and high-quality finishes. In this article, we will delve into what leather feet are, their benefits, and tips on how to choose the right one for your sewing machine.

What is a Leather Foot?

A leather foot, also known as a teflon foot or walking foot, is a presser foot specifically designed for sewing leather. Unlike standard presser feet, leather feet have a smooth or teflon-coated surface that allows them to glide over the leather without pulling or dragging the material. This feature is crucial, as leather tends to be thicker and stickier than conventional fabrics, which can lead to misalignment and uneven stitching if not handled properly.

Benefits of Using a Leather Foot

1. Smooth Feeding One of the primary advantages of using a leather foot is the improved feeding of the leather material. The specialized design helps in preventing the leather from sticking to the foot, allowing for a smoother sewing experience.

2. Consistent Stitching A leather foot enables more consistent stitches by keeping the leather in place while sewing. This is particularly important when working on intricate patterns or when joining multiple layers of leather.

3. Reduced Damage Leather is a sensitive material that can easily be damaged by the wrong tools. A leather foot minimizes the risk of puncturing or scratching the surface, resulting in a cleaner and more professional finish.

Choosing the Right Leather Foot

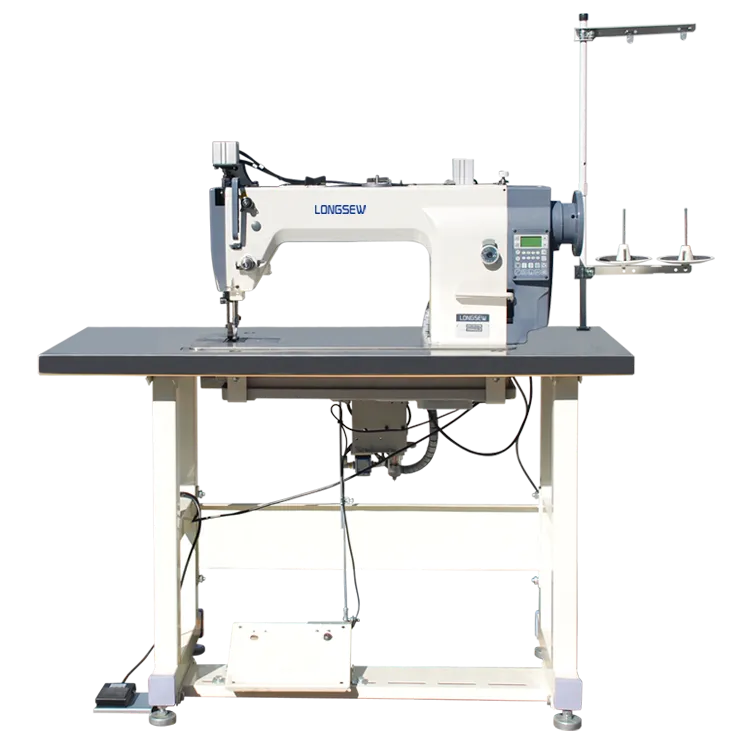

leather foot for sewing machine

When selecting a leather foot for your sewing machine, there are several factors to consider

- Compatibility Ensure that the leather foot you choose is compatible with your specific sewing machine model. Most manufacturers create presser feet tailored to their machines, so always check the specifications first.

- Material While teflon feet are the most common, there are various types of leather feet, including walking feet and roller feet. Each has unique features; for instance, walking feet have added layers of feed dogs for better handling of thicker materials.

- Thickness Depending on the type of leather you plan to sew, you may require a foot that can handle various thicknesses. Some leather feet come with adjustable features that can accommodate different fabric weights.

Tips for Sewing Leather with a Leather Foot

1. Use the Right Needle Always use a leather needle designed for heavy materials to avoid damaging the leather.

2. Adjust Tension Ensure that the sewing machine's tension is appropriately set for leather. Generally, a looser tension works best to accommodate the flexing nature of leather.

3. Test Before You Sew Always perform a test stitch on a scrap piece of leather. This allows you to adjust the stitch length and tension before starting your project.

In conclusion, investing in a leather foot for your sewing machine is crucial if you're looking to work with leather effectively. By ensuring smooth feeding, consistent stitching, and reduced damage, a leather foot can greatly enhance your sewing experience. With the right tools and techniques, you’ll be well on your way to creating beautiful leather projects. Happy sewing!

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025