Efficient Stitching Machines for Crafting High-Quality Leather Bags and Accessories

The Importance of Leather Bag Stitching Machines in Modern Craftsmanship

In the world of leather goods, creating high-quality products requires precision, craftsmanship, and the right tools. Among these essential tools, leather bag stitching machines play a pivotal role in ensuring the durability and aesthetic appeal of leather bags. These machines have revolutionized the leatherworking industry, combining traditional techniques with modern technology to produce items that meet both functionality and style.

Leather bags have long been a staple in fashion, serving not just as an accessory but also as a practical item for everyday use. With the rising demand for high-quality leather bags, manufacturers and artisans are compelled to invest in efficient sewing solutions. Leather bag stitching machines are designed specifically to handle the unique challenges posed by leather, which tends to be thicker and less forgiving than standard fabric materials.

One of the key benefits of using a leather bag stitching machine is the consistency it offers. Unlike hand stitching, which may vary in tightness and appearance depending on the skill of the artisan, machines provide uniform stitches that enhance the overall quality of the product. This consistency is crucial, especially when producing items in large quantities where each piece must match the next in both function and aesthetic quality.

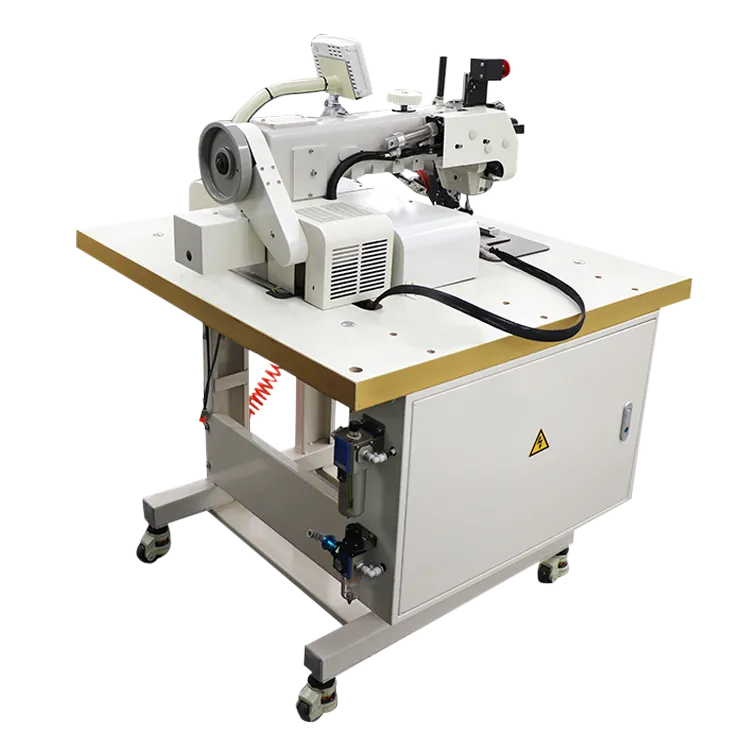

leather bag stitching machine

Another advantage of these specialized machines is their ability to stitch through multiple layers of leather with ease. Leather bags often consist of various components—outer shells, linings, pockets, and closures—all of which require robust stitching to withstand daily use. Leather bag stitching machines are engineered to handle these complexities, ensuring that every seam is strong and reliable. This durability is not only important for the longevity of the bag but also contributes to customer satisfaction, as consumers increasingly seek out products that can endure the rigors of everyday wear.

Furthermore, the integration of advanced technology into leather bag stitching machines has expanded the possibilities for design. Many modern machines come equipped with digital interfaces, allowing artisans to program custom stitch patterns, adjust tension settings, and even use embroidery features. This versatility gives designers greater freedom to experiment with creative patterns and embellishments, elevating the aesthetics of leather bags beyond traditional designs.

However, while machines add remarkable efficiencies to the production process, the artistry of leatherworking still remains in the hands of skilled artisans. The use of stitching machines complements the techniques that craftsmen have honed over generations. It is the combination of manual skills and machine precision that results in the stunning leather bags that we see in the market today. Artisans can focus more on the design and quality control aspects while relying on machines to handle the more labor-intensive stitching processes.

In conclusion, leather bag stitching machines have become an indispensable asset in the leatherworking industry. They enhance production efficiency, maintain quality through consistent stitching, and allow for creative design possibilities. As the market for leather goods continues to grow, the importance of these machines will likely increase, marrying tradition with innovation and ensuring that the art of leather crafting can thrive in the modern age. For both manufacturers and consumers alike, investing in high-quality leather bag stitching machines is a step toward achieving excellence in leather craftsmanship.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025