leather bag stitching machine

The Evolution and Importance of Leather Bag Stitching Machines

In today’s world, craftsmanship often blends with technology, especially in the fashion industry where items like leather bags are not just practical accessories but also reflections of personal style and quality. At the heart of crafting these exquisite items lies a crucial component the leather bag stitching machine. This machine has revolutionized the way leather goods are produced, enhancing both the speed and quality of the final product.

The Art of Leather Bag Making

Creating a leather bag involves a series of meticulous processes, from selecting high-quality leather to cutting, sewing, and finishing. Traditionally, skilled artisans performed these tasks by hand. While this method can produce beautifully detailed and unique pieces, it is labor-intensive and time-consuming. As demand for leather goods grew, especially in the fashion sector, the need for more efficient production methods became apparent.

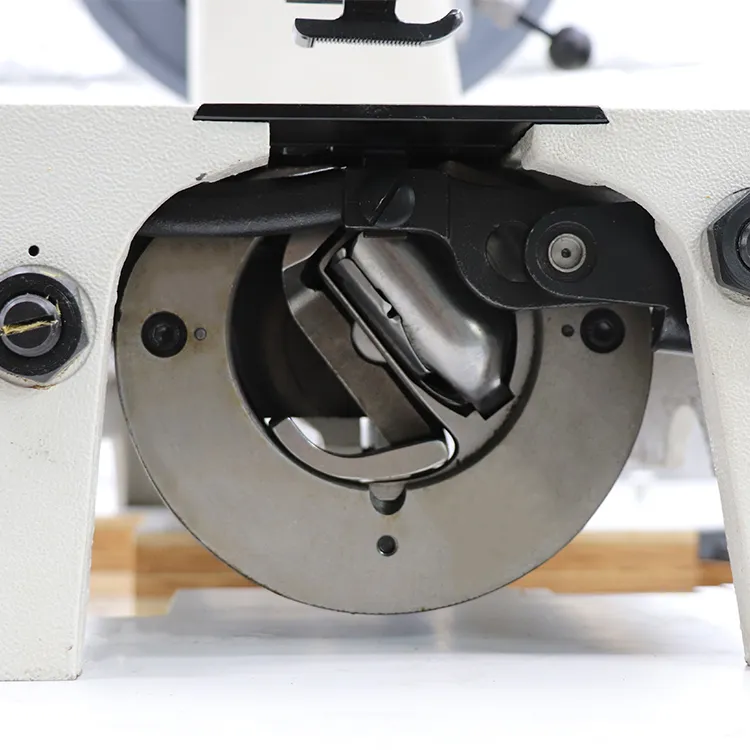

Enter the leather bag stitching machine. These machines have streamlined the bag-making process by significantly reducing the time it takes to sew components together while maintaining high standards of quality. Modern stitching machines are designed to handle various types of leather, accommodating different thicknesses and textures, which allows for a wide range of designs.

Features of Modern Leather Bag Stitching Machines

Today's leather bag stitching machines come equipped with numerous features that enhance their functionality. Many machines offer adjustable stitch lengths, allowing for customization based on the type of leather and the desired aesthetic effect. Some high-end models include computerized controls, enabling users to program specific stitching patterns and sequences, resulting in consistent and intricate designs that might be difficult to achieve by hand.

leather bag stitching machine

Additionally, these machines often feature walking feet that keep the leather securely in place while sewing. This is particularly important because leather can be slippery and may shift during the stitching process. The walking foot mechanism ensures that every layer is fed evenly, preventing puckering and uneven seams, which are detrimental to both the appearance and durability of the bag.

The Benefits of Using Stitching Machines

Utilizing a leather bag stitching machine comes with numerous advantages. Firstly, efficiency is significantly improved. Where a skilled artisan might take hours to complete a single bag, a machine can produce multiple bags in the same period, meeting the demands of a growing market. This scalability is vital for manufacturers who need to balance quality with quantity.

Secondly, the precision offered by stitching machines reduces the risk of human error. Even the most experienced craftsman can make mistakes, which can be costly in terms of wasted materials and time. Machines provide uniformity, ensuring that each bag meets the same high standards, which is essential for branding and customer satisfaction.

Lastly, advancements in stitching technology have made it possible to use a wider variety of materials and designs. From embossed patterns to complex color combinations, modern leather bag stitching machines can handle intricate work that enhances the visual appeal of the product.

Conclusion

As the demand for leather bags continues to grow, the importance of efficient and high-quality production methods becomes increasingly clear. Leather bag stitching machines have emerged as indispensable tools in the manufacturing process, bridging the gap between traditional craftsmanship and modern production techniques. With their ability to enhance efficiency, precision, and versatility, these machines not only uphold the quality of leather goods but also ensure that the art of bag-making remains vibrant in the contemporary marketplace. As technology continues to evolve, we can only anticipate further innovations that will shape the future of leather craftsmanship.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025