Leather Bag Production Equipment for Efficient Manufacturing Solutions

The Evolution and Importance of Leather Bag Making Machines

The craft of leather bag making has a long and rich history, evolving from handcrafted techniques to the integration of modern technology. Leather bags have been a staple accessory for centuries, combining functionality and elegance. As the demand for high-quality leather goods continues to rise, so does the necessity for efficient leather bag making machines, which play a pivotal role in the production process.

Understanding Leather Bag Making Machines

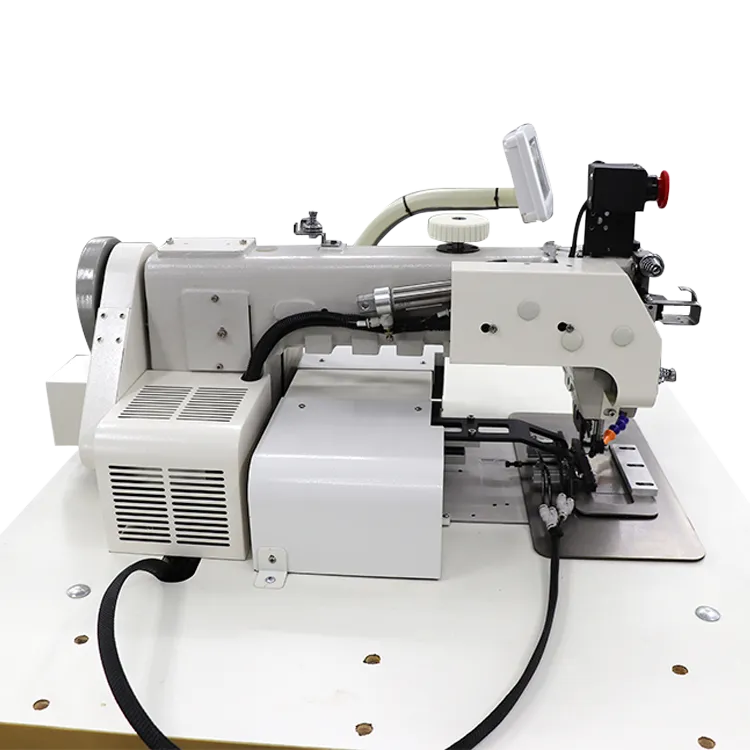

Leather bag making machines are specialized equipment designed to automate various aspects of leather processing and bag assembly. These machines vary in function, including cutting, stitching, edging, and finishing, streamlining the manufacturing process. By leveraging technology, these machines enhance precision and speed, significantly reducing production time while maintaining high-quality standards.

Types of Leather Bag Making Machines

1. Leather Cutting Machines These machines are essential for cutting leather into specific shapes and sizes required for bag components. Laser cutting machines have gained popularity due to their precision and ability to create intricate designs without damaging the material.

2. Stitching Machines After cutting, the next step involves stitching the leather pieces together. Industrial sewing machines designed for leather have heavy-duty capabilities to handle thick materials and provide robust seams.

3. Edging and Finishing Machines Edging machines give the leather a finished look by sealing the edges, which prevents fraying and enhances durability. Finishing machines apply dyes, conditioners, or protective coatings to ensure the leather remains supple and aesthetically appealing.

4. Embossing and Printing Machines For brands aiming to create a unique identity, embossing machines can add intricate patterns or logos to leather surfaces, elevating the bag's visual appeal.

The Benefits of Using Leather Bag Making Machines

Increased Efficiency One of the most significant advantages of using machinery in leather bag production is the dramatic increase in efficiency. Machines can perform tasks much faster and with more consistency than manual labor. This allows manufacturers to meet the growing consumer demand without compromising quality.

leather bag making machine

Cost-Effectiveness While the initial investment in machinery may be high, the long-term savings are considerable. Automating processes reduces labor costs and minimizes material wastage, resulting in better profit margins.

Enhanced Precision Machines provide a level of precision that is difficult to achieve manually. This is particularly important in leather bag making, where even minor discrepancies can affect the final product's quality and appearance.

Customization Opportunities Modern leather bag making machines often come equipped with computerization capabilities that allow for easy adjustments and customization. This means that manufacturers can quickly adapt to fashion trends or customer preferences without a complete overhaul of their production line.

The Growing Market for Leather Goods

The leather goods market has seen substantial growth in recent years, driven by increased consumer interest in quality and sustainable products. As more people seek out leather bags that combine durability with style, manufacturers are challenged to keep up with demand while adhering to environmentally friendly practices.

In response, many companies are turning to leather bag making machines that prioritize eco-friendly production methods. For example, some machines now use less energy and generate less waste, aligning production practices with the growing emphasis on sustainability.

Future Trends in Leather Bag Making

As technology continues to advance, the future of leather bag making machines looks promising. We can expect the integration of artificial intelligence (AI) and machine learning, improving predictive maintenance and optimizing production processes. Additionally, the rise of 3D printing technology presents new opportunities for creating complex bag designs that were previously unimaginable.

Furthermore, as consumers become more environmentally conscious, manufacturers will likely invest in more sustainable machine technologies that reduce the environmental impact of leather production.

Conclusion

The journey of leather bag making machines reflects the intersection of tradition and innovation. These machines are revolutionizing the leather goods industry, making it possible to produce high-quality bags efficiently while meeting the diverse needs of consumers. As the leather market continues to evolve, embracing technological advancements will be essential for manufacturers seeking to thrive in a competitive landscape. Ultimately, the integration of machinery in leather bag production not only enhances productivity but also ensures that the artistry and craftsmanship of leather goods are preserved for future generations.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025