leather sewing machine manual

Understanding Leather Sewing Machines A Comprehensive Manual

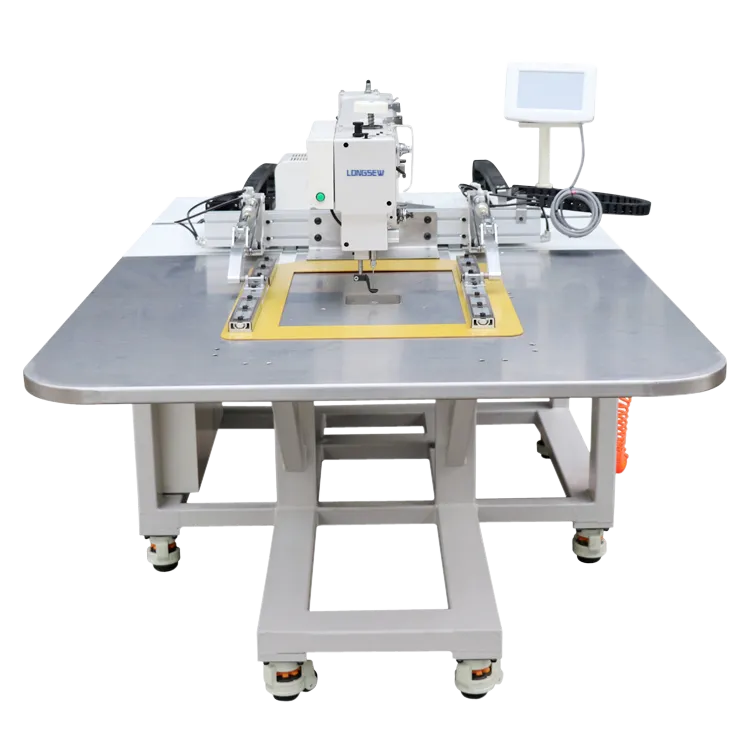

Leather sewing machines are specialized tools designed for stitching leather and other heavy materials, making them essential for artisans, leatherworkers, and hobbyists alike. To fully harness the potential of these machines, it's crucial to understand their components, functionalities, and maintenance through an appropriate manual.

Overview of Leather Sewing Machines

Leather sewing machines differ from standard sewing machines primarily in their construction and capabilities. They are equipped with robust motors, heavy-duty needles, and stronger feed mechanisms to handle the thickness and density of leather. These machines often feature walking feet or roller feet that help prevent slipping and ensure even feed of the material, which is essential when working with slippery or thick materials.

Key Components

1. Needles Leather sewing requires special needles that are designed to penetrate thick fabrics without causing damage. Common needle types include leather needles with a wedge-shaped tip, which can efficiently pierce through multiple layers of leather.

2. Feed System The feed dogs and presser feet are essential for moving the leather through the machine. Walking feet, with their dual-action feeding, are particularly useful as they help to maintain the alignment of the leather as it is stitched.

3. Stitching Mechanisms Leather sewing machines can generally create a variety of stitches, including straight stitches, zigzag stitches, and decorative patterns. Understanding how to adjust stitch length and tension is vital for achieving professional results.

Setting Up Your Machine

Before you begin sewing, make sure to read your machine's manual thoroughly. Setting up involves several steps

leather sewing machine manual

- Assembling the Machine Ensure that all components are correctly assembled, including the needle, bobbin, and presser foot. - Choosing the Right Thread Use heavy-duty polyester or nylon thread, as cotton threads may not provide the necessary strength. - Dialing in the Tension Adjust the thread tension according to the thickness of the leather. Too much tension can cause thread breakage, while too little can result in loose stitches.

Sewing Techniques

When sewing leather, consider the following techniques for optimal results

- Cutting Leather Always use a sharp, rotary cutter or a knife designed for leather to achieve clean, precise edges before sewing. - Pinning and Clipping Use clips rather than pins to hold leather pieces together, as pins can leave holes and disrupt the material's integrity. - Testing Stitches Before starting on your main project, always test your settings and stitches on a scrap piece of leather to ensure satisfactory results.

Maintenance

Regular maintenance is vital for the longevity of your leather sewing machine

- Cleaning After each use, remove any dust, lint, or debris. Use a soft brush or compressed air to clean hard-to-reach areas. - Oiling Follow your manual's instructions on oiling the machine to keep it running smoothly. Regular lubrication reduces friction and wear on moving parts.

Conclusion

Leather sewing machines offer unparalleled precision and durability when working with leather. By familiarizing yourself with the machine's components, adjusting settings, and maintaining your equipment, you can achieve impressive results that showcase your craftsmanship. Whether you are a seasoned leatherworker or a novice, understanding your sewing machine through a well-detailed manual is the key to successful leather projects. With practice and patience, your skills will flourish, enhancing your creativity and craftsmanship in leatherwork.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025