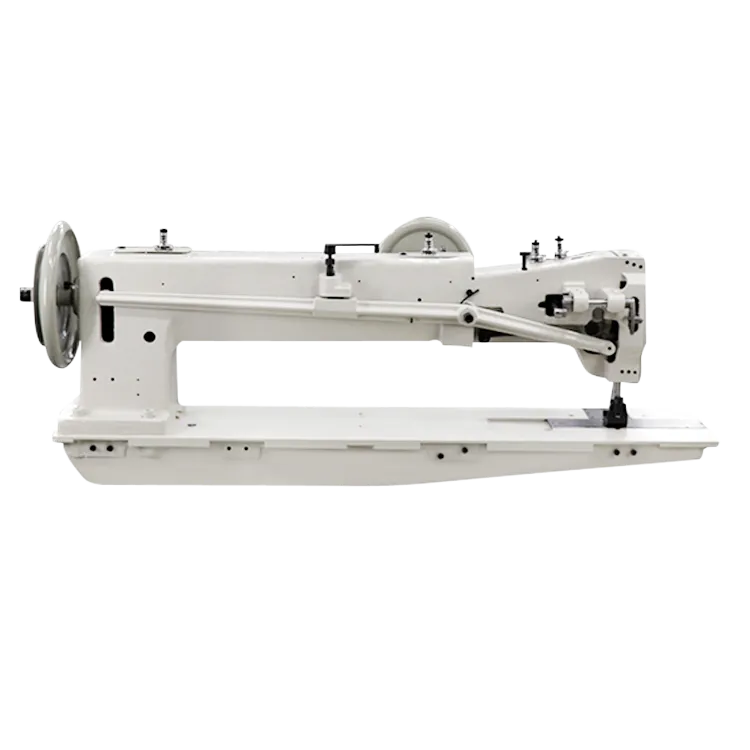

jute bag closer machine

The Importance of Jute Bag Closer Machines in Sustainable Packaging

In recent years, the global emphasis on sustainability has led to a significant surge in the use of biodegradable materials. Among these, jute—a natural fiber derived from the Jute plant—has gained popularity as an eco-friendly alternative to plastic. The increasing demand for jute products, particularly jute bags, has prompted manufacturers to invest in efficient production techniques. One such vital piece of equipment is the jute bag closer machine, which plays a significant role in ensuring the quality and durability of jute bags used for packaging.

Jute bag closer machines are engineered to seal the open ends of jute bags securely. They employ various methods, including stitching, gluing, or heat sealing, depending on the design and purpose of the bags. The efficiency and precision of these machines are crucial for producing high-quality jute bags that can withstand the rigors of transportation and storage. In an era where consumers are more conscious of sustainability, the reliability of jute bags can greatly influence purchasing decisions.

One of the major advantages of using jute bag closer machines is that they enhance productivity. Automating the bag closing process reduces labor costs and speeds up production rates, allowing manufacturers to meet rising consumer demand efficiently. This automated approach minimizes human error, ensuring that each bag is closed uniformly and tightly, thus reducing the chance of product loss during shipping. In addition, consistent sealing helps maintain the integrity of the contents, whether they are agricultural products, grains, or retail items.

jute bag closer machine

Moreover, investing in jute bag closer machines is an environmentally responsible choice. By promoting the use of jute bags over plastic, these machines contribute to reducing plastic waste and its detrimental effects on the environment. Jute is biodegradable and compostable, making it a sustainable option that aligns with the global push towards eco-friendly practices. Manufacturers that use jute bags demonstrate a commitment to sustainability, which can enhance their brand image and attract environmentally conscious consumers.

Furthermore, advances in technology have led to the development of more sophisticated jute bag closer machines. Modern machines are equipped with features such as adjustable stitching speeds, user-friendly interfaces, and the ability to handle various bag sizes and weights. This versatility allows manufacturers to cater to diverse market needs, making it easier to pivot and adapt to new trends in packaging.

In conclusion, jute bag closer machines are an indispensable asset in the growing market for sustainable packaging solutions. As the demand for eco-friendly options continues to rise, these machines provide manufacturers with the efficiency, reliability, and adaptability needed to succeed in a competitive landscape. By facilitating the production of high-quality jute bags, they not only support sustainable practices but also help meet the global challenge of reducing plastic waste, paving the way for a greener future.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025