Jan . 09, 2025 13:42

Back to list

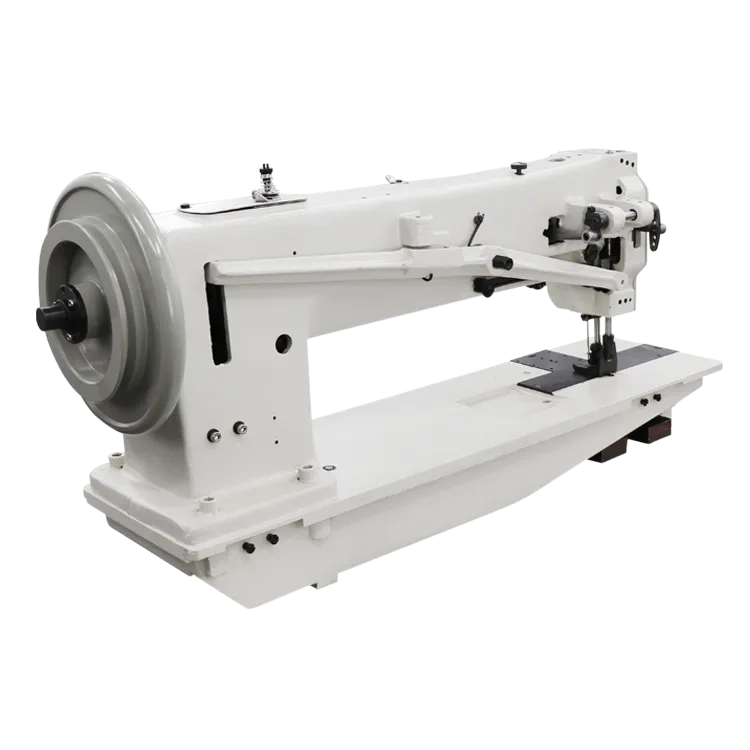

jumbo bag stitching machine

Navigating the world of industrial production, one often encounters the importance of efficiency and precision. Central to this is the jumbo bag stitching machine, a vital tool in the manufacturing and packaging sector. This machine is not just an asset; it's a game-changer for industries relying heavily on bulk packaging to streamline operations and boost productivity.

Operator safety is another critical aspect underscored by the design of modern jumbo bag stitching machines. Manufacturers have integrated safety mechanisms that protect operators without compromising on the machine's output. Features such as automatic shutdown and emergency stop buttons are prevalent, ensuring that the safety of the workforce is prioritised alongside operational efficiency. Moreover, trust in these machines is bolstered by the comprehensive support and training often provided by manufacturers. Expert training programs ensure operators are well-versed in both the technical and safety aspects, promoting a culture of expertise within the workforce. This not only enhances productivity but also builds employer confidence in the technology they are investing in. The eco-friendly aspect cannot be overlooked in today’s conscientious market. Many modern jumbo bag stitching machines are designed with sustainability in mind, utilizing energy-efficient components that reduce the carbon footprint. This aligns with global initiatives to promote environmentally friendly practices in industrial operations and serves as an attractive proposition for companies looking to boost their sustainability credentials. In conclusion, the jumbo bag stitching machine is more than a mere tool—it's an integral part of modern industrial operations. Its efficacy in enhancing productivity, combined with its adaptability, technical prowess, safety measures, and sustainability, make it an invaluable asset. As industries continue to evolve, the importance of such precise and efficient machinery will only grow, solidifying the position of the jumbo bag stitching machine as a cornerstone in the realm of bulk packaging solutions.

Operator safety is another critical aspect underscored by the design of modern jumbo bag stitching machines. Manufacturers have integrated safety mechanisms that protect operators without compromising on the machine's output. Features such as automatic shutdown and emergency stop buttons are prevalent, ensuring that the safety of the workforce is prioritised alongside operational efficiency. Moreover, trust in these machines is bolstered by the comprehensive support and training often provided by manufacturers. Expert training programs ensure operators are well-versed in both the technical and safety aspects, promoting a culture of expertise within the workforce. This not only enhances productivity but also builds employer confidence in the technology they are investing in. The eco-friendly aspect cannot be overlooked in today’s conscientious market. Many modern jumbo bag stitching machines are designed with sustainability in mind, utilizing energy-efficient components that reduce the carbon footprint. This aligns with global initiatives to promote environmentally friendly practices in industrial operations and serves as an attractive proposition for companies looking to boost their sustainability credentials. In conclusion, the jumbo bag stitching machine is more than a mere tool—it's an integral part of modern industrial operations. Its efficacy in enhancing productivity, combined with its adaptability, technical prowess, safety measures, and sustainability, make it an invaluable asset. As industries continue to evolve, the importance of such precise and efficient machinery will only grow, solidifying the position of the jumbo bag stitching machine as a cornerstone in the realm of bulk packaging solutions.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025