Jan . 09, 2025 12:07

Back to list

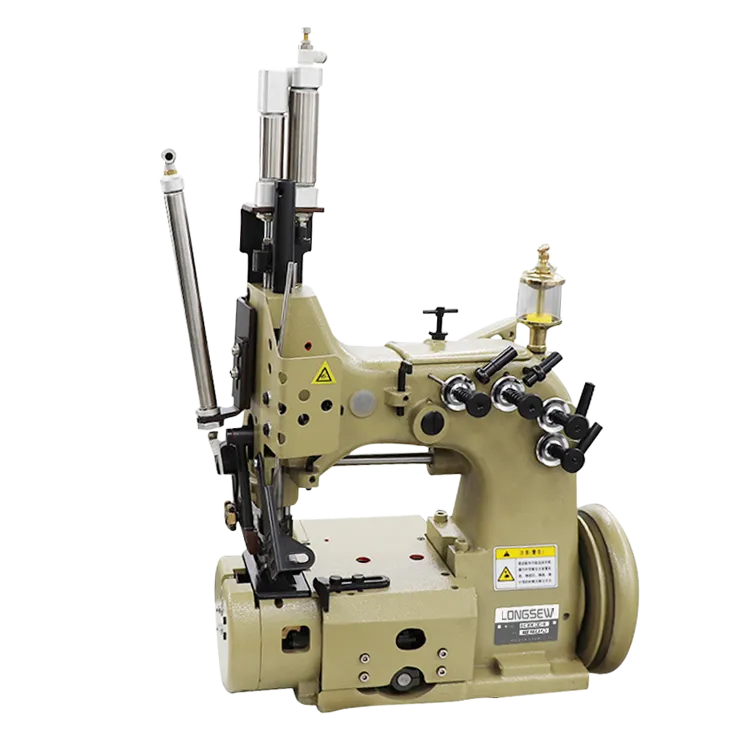

jumbo bag stitching machine

In the ever-evolving landscape of industrial manufacturing, the jumbo bag stitching machine plays a crucial role in ensuring efficiency and reliability in the packaging sector. This specialized machinery is tailored for stitching jumbo bags, also known as FIBCs (Flexible Intermediate Bulk Containers), which are widely used for transporting large quantities of goods such as grains, chemicals, and minerals. An understanding of the intricate details and functions of this machine can provide invaluable insights into its operational advantages.

From an authoritative perspective, jumbo bag stitching machines are manufactured by industry leaders who invest heavily in research and development. This dedication is evident in the continuous upgrades and advancements seen in new models. These innovations promise superior performance through enhanced speed, accuracy, and user-friendly interfaces. Companies that produce these machines often provide comprehensive training and technical support, reinforcing their authority and commitment to customer success. The credibility of jumbo bag stitching machines is also rooted in their adherence to international safety and quality standards. Certifications such as ISO and CE ensure that these machines comply with global regulations, guaranteeing safe operations and reliable outputs. This compliance, coupled with extensive warranty schemes, builds trust with the end-users, who can rely on the machinery's performance without apprehension of unexpected failures. In conclusion, jumbo bag stitching machines embody a synthesis of experience, expertise, authority, and trust. By focusing on precision, adaptability, and technological advancements, these machines not only meet but often exceed the demands of industrial packaging. They stand as a testament to the evolution of manufacturing technology, offering indispensable solutions that drive efficiency and productivity across various sectors.

From an authoritative perspective, jumbo bag stitching machines are manufactured by industry leaders who invest heavily in research and development. This dedication is evident in the continuous upgrades and advancements seen in new models. These innovations promise superior performance through enhanced speed, accuracy, and user-friendly interfaces. Companies that produce these machines often provide comprehensive training and technical support, reinforcing their authority and commitment to customer success. The credibility of jumbo bag stitching machines is also rooted in their adherence to international safety and quality standards. Certifications such as ISO and CE ensure that these machines comply with global regulations, guaranteeing safe operations and reliable outputs. This compliance, coupled with extensive warranty schemes, builds trust with the end-users, who can rely on the machinery's performance without apprehension of unexpected failures. In conclusion, jumbo bag stitching machines embody a synthesis of experience, expertise, authority, and trust. By focusing on precision, adaptability, and technological advancements, these machines not only meet but often exceed the demands of industrial packaging. They stand as a testament to the evolution of manufacturing technology, offering indispensable solutions that drive efficiency and productivity across various sectors.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025