Sewing Machines for Jumbo Bags Efficient Production and High-Quality Stitching Solutions

The Importance of Jumbo Bag Sewing Machinery in Modern Manufacturing

In the world of industrial packaging, jumbo bags, also known as FIBC (Flexible Intermediate Bulk Containers), play a crucial role in the transportation and storage of bulk materials. From agriculture to construction, these large bags are essential for moving products such as grains, fertilizers, chemicals, and building materials. To meet the growing demand for jumbo bags, the efficiency and reliability of the sewing machinery used in their production are paramount.

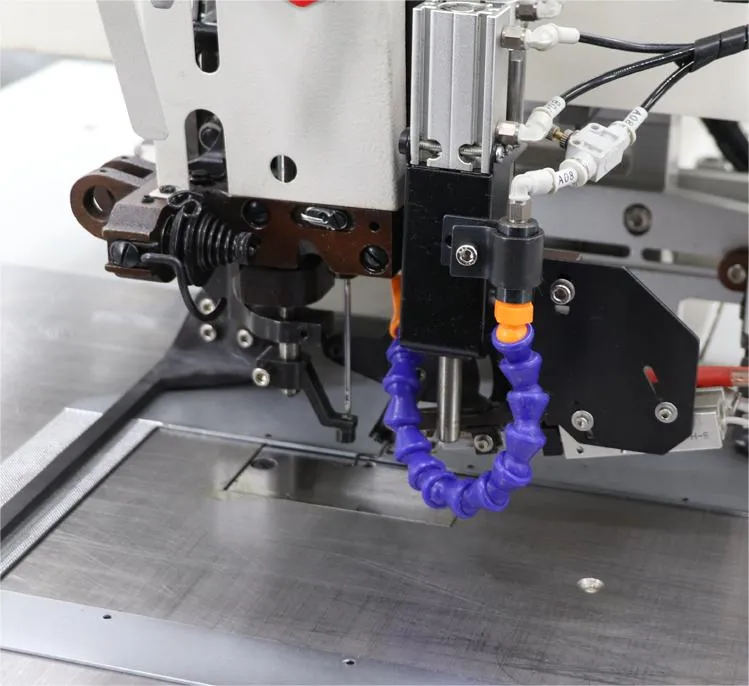

Jumbo bag sewing machinery is specialized equipment designed specifically for the task of sewing heavy-duty fabrics. Traditional sewing machines are often inadequate for this purpose, as they struggle with thicker materials and larger dimensions. In contrast, jumbo bag sewing machines are equipped with robust motors and specialized needles that can handle the thick polypropylene and polyester fabrics commonly used in the manufacturing of these bags. This machinery not only ensures precision in stitching but also enhances the durability of the bags, crucial for maintaining safety during the handling of heavy bulk items.

jumbo bag sewing machinery

One of the notable advancements in jumbo bag sewing machinery is the introduction of automated systems. Automation minimizes human error and increases production speed, allowing manufacturers to meet higher demand without compromising quality. These machines can perform various functions, including seam sealing and reinforced stitching, which are essential for preventing leaks and ensuring the integrity of the bag under heavy loads. Additionally, computerized sewing machines offer the flexibility of adjusting stitch patterns and sizes, making it easier for manufacturers to produce customized bags for different applications.

Moreover, the efficiency of jumbo bag sewing machinery contributes to sustainable practices in manufacturing. By improving the quality of the bags, companies can reduce waste caused by damaged products. Furthermore, the use of advanced machinery often leads to a decrease in energy consumption, making for a more eco-friendly production process.

In conclusion, jumbo bag sewing machinery is a vital component in the supply chain of various industries. With advancements in technology, these machines not only enhance productivity but also ensure the quality and sustainability of the products being manufactured. As industries continue to evolve and grow, the role of efficient sewing machinery will remain indispensable in supporting the bulk packaging requirements of the future. Companies that invest in modern sewing technology will not only improve their operational efficiency but also gain a competitive edge in the marketplace.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025