Jan . 09, 2025 12:37

Back to list

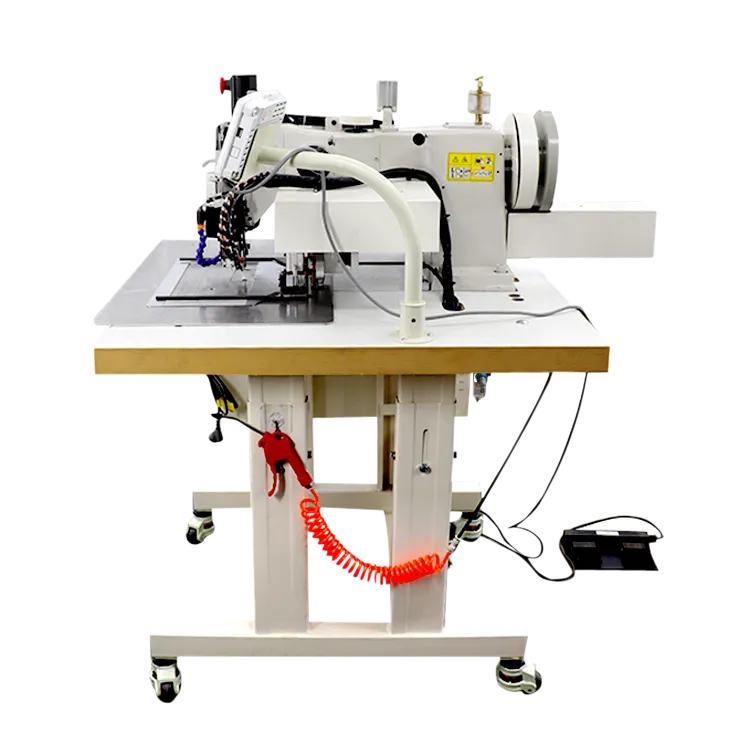

jumbo bag sewing machine

Choosing the right jumbo bag sewing machine can significantly impact your production efficiency and product quality. Having spent over two decades in the textile industry, I’ve seen firsthand the transformative power of selecting a machine tailored to specific needs. Here's a comprehensive guide that delves into the experience-backed benefits of investing in a high-quality jumbo bag sewing machine.

From an authoritative standpoint, the durability and build quality of a sewing machine cannot be understated. Industry experts often recommend assessing the machine’s frame and motor capacity, ensuring they are designed to withstand extended use. A well-constructed machine minimizes downtime and maintenance, which is critical in maintaining production deadlines. Leading brands often provide extensive warranties and customer support, adding an extra layer of assurance regarding the machine's reliability and performance. This support is invaluable, particularly when troubleshooting or requiring specific machine parts. Finally, trustworthiness in your jumbo bag sewing machine is built through consistent performance and the operational insights provided by data tracking capabilities. Modern machines often include sensors and diagnostic tools that offer real-time data regarding equipment health and production metrics. These features allow for preventative maintenance, reducing unexpected malfunctions. Trust, therefore, is not only in the machine's immediate performance but also in its long-term dependability. To encapsulate, investing in a jumbo bag sewing machine that aligns with your operational goals is not just about immediate output. It’s about ensuring longevity, quality, and adaptability amidst evolving production demands. This investment, grounded in experience and expertise, is a testament to a commitment to excellence that not only positions your business as an industry leader but also assures clients of your dedication to delivering superior products.

From an authoritative standpoint, the durability and build quality of a sewing machine cannot be understated. Industry experts often recommend assessing the machine’s frame and motor capacity, ensuring they are designed to withstand extended use. A well-constructed machine minimizes downtime and maintenance, which is critical in maintaining production deadlines. Leading brands often provide extensive warranties and customer support, adding an extra layer of assurance regarding the machine's reliability and performance. This support is invaluable, particularly when troubleshooting or requiring specific machine parts. Finally, trustworthiness in your jumbo bag sewing machine is built through consistent performance and the operational insights provided by data tracking capabilities. Modern machines often include sensors and diagnostic tools that offer real-time data regarding equipment health and production metrics. These features allow for preventative maintenance, reducing unexpected malfunctions. Trust, therefore, is not only in the machine's immediate performance but also in its long-term dependability. To encapsulate, investing in a jumbo bag sewing machine that aligns with your operational goals is not just about immediate output. It’s about ensuring longevity, quality, and adaptability amidst evolving production demands. This investment, grounded in experience and expertise, is a testament to a commitment to excellence that not only positions your business as an industry leader but also assures clients of your dedication to delivering superior products.

Previous:

Next:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025