Optimizing Jumbo Bag Manufacturing with Lock Stitch Sewing Techniques for Enhanced Durability and Efficiency

The Importance of Jumbo Bag Lock Stitch Sewing

In the world of industrial sewing, the techniques and materials used can significantly impact the quality and longevity of the final product. One such crucial technique is the lock stitch, particularly when applied to jumbo bags. These bags, often used for bulk packaging and transportation of various products, require special attention to detail in their construction to ensure they withstand the rigors of handling and transportation.

What is a Jumbo Bag?

Jumbo bags, also known as FIBCs (Flexible Intermediate Bulk Containers), are large sacks designed to hold and transport bulk materials. They are commonly used in industries such as agriculture, construction, chemicals, and food. These bags typically can hold between 500 kg to 2000 kg of materials, making their durability and strength essential. The lock stitch sewing technique plays a critical role in providing the necessary structural integrity that jumbo bags require.

Understanding Lock Stitch Sewing

Lock stitch sewing is a method where two threads, one from the top and one from the bottom, intertwine to create a secure stitch. This technique offers numerous advantages, particularly when sewing heavy-duty materials such as those used in jumbo bags. The resulting stitch is tight and reliable, which is essential for handling significant weight without risking seam failure.

Why Lock Stitch is Ideal for Jumbo Bags

1. Strength and Durability The interlocking nature of the lock stitch provides superior strength compared to other stitching techniques. When manufactured correctly, lock stitches can bear substantial loads, making them perfect for services that require high-performance standards.

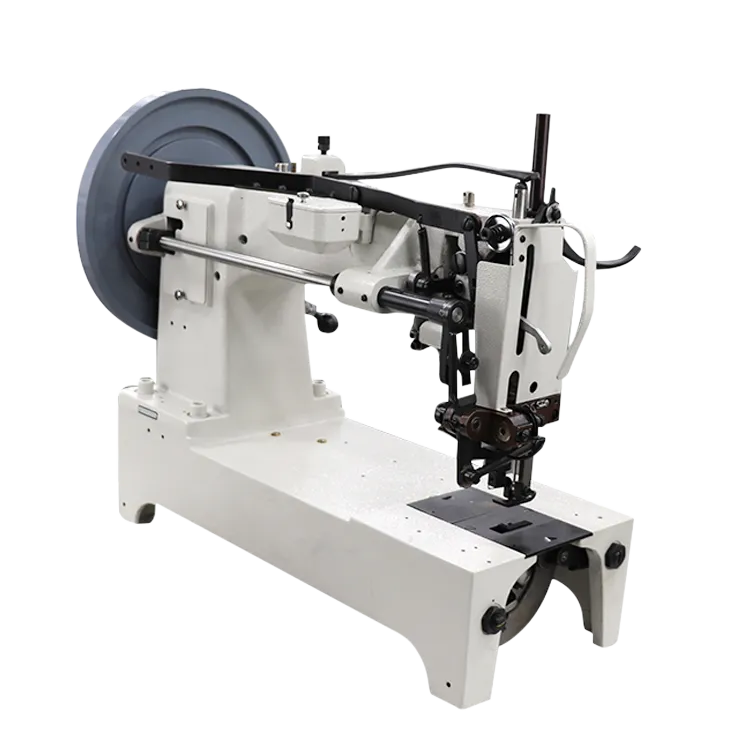

jumbo bag lock stitch sewing

2. Resistance to Unraveling One of the most significant risks associated with sewing is the potential for stitches to unravel under stress. Lock stitches, due to their design, resist unraveling more effectively than other methods, ensuring that jumbo bags maintain their structural integrity even under challenging conditions.

3. Versatility Lock stitch sewing can be used on various materials, including woven polypropylene, polyethylene, and other heavy-duty fabrics commonly found in jumbo bags. This versatility makes it a go-to choice for manufacturers looking to produce high-quality products without compromising on material choice.

4. Aesthetic Appeal In addition to functionality, lock stitches also offer a cleaner and more aesthetically pleasing finish. This becomes crucial when bags are meant to represent brand images, as a neatly sewn bag conveys professionalism and quality.

The Manufacturing Process

The sewing of jumbo bags using lock stitch technology involves several steps. First, the materials are cut to size, accounting for the dimensions and shape of the final product. Next, the edges are typically folded and hemmed to prevent fraying. The sewing machine is then set up with the appropriate thread tension and stitch length, ensuring that every stitch is consistent and secure. Quality control is paramount during this phase, as any defects can compromise the entire bag's performance.

Conclusion

Jumbo bag lock stitch sewing is an indispensable technique in the manufacturing of durable, high-capacity bags for various industries. Its robust nature ensures that products remain safe during transportation, while also providing aesthetic benefits that can enhance brand image. The reliability, strength, and precision offered by lock stitch sewing make it the preferred choice for manufacturers focused on quality and performance. As industries continue to evolve, the importance of such techniques in maintaining efficiency and safety will only grow. Thus, understanding and implementing effective sewing methods like lock stitch will remain vital for any manufacturer involved in producing jumbo bags.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025