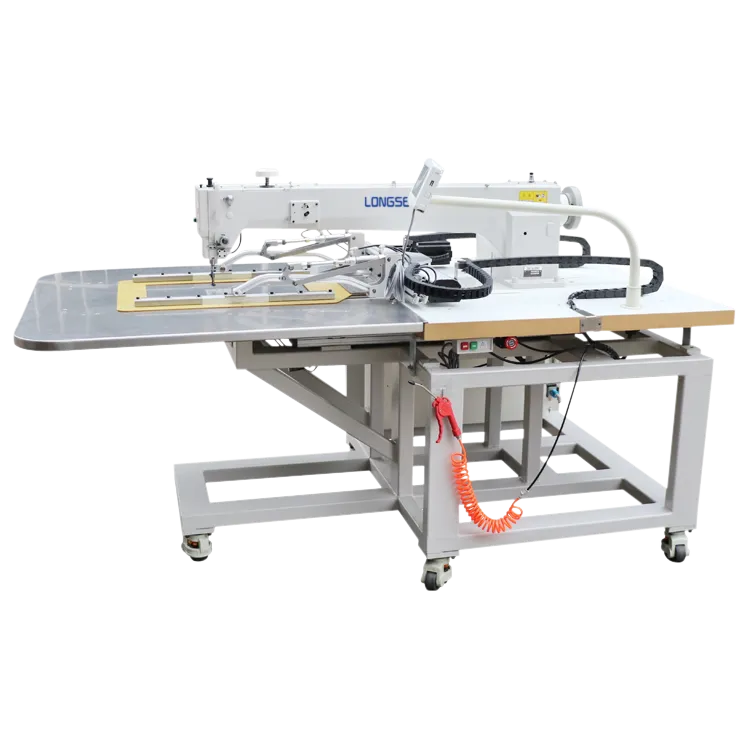

Heavy-Duty Jumbo Bag Sewing Machine with Double Needle for Durable Stitching

Exploring the Jumbo Bag Double Needle Sewing Machine

In the world of textile manufacturing, the efficiency and quality of sewing machines play a critical role in determining the success of any operation. Among various types of sewing equipment, the Jumbo Bag Double Needle Sewing Machine stands out as a vital tool for manufacturers focusing on the production of heavy-duty bags and industrial textiles. This specialized machine is designed to handle thicker materials, making it ideal for creating sturdy jumbo bags commonly used for packaging bulk goods like grains, fertilizers, and construction materials.

Exploring the Jumbo Bag Double Needle Sewing Machine

User-friendly controls and adjustable settings make the Jumbo Bag Double Needle Sewing Machine accessible for operators of all skill levels. Modern machines are equipped with automatic features such as thread tension adjustment and stitch length selection, ensuring a consistent and professional finish with minimal manual intervention. Moreover, these machines are built with durability in mind, often featuring reinforced frames and components that withstand the rigors of industrial sewing.

jumbo bag double needle sewing machine

Maintenance is crucial for the longevity and performance of any sewing machine, and the Jumbo Bag Double Needle Sewing Machine is no exception. Regular lubrication, proper tension adjustments, and timely replacement of worn-out needles are essential practices that users must adopt. Investing in training for operators can further enhance the efficiency of these machines, ensuring they are utilized to their full potential.

With the increasing demand for eco-friendly packaging solutions, many manufacturers are also exploring biodegradable materials for jumbo bags. The versatility of the Jumbo Bag Double Needle Sewing Machine allows for easy adaptation to different fabric types, making it an excellent choice for businesses looking to innovate and meet market trends.

In conclusion, the Jumbo Bag Double Needle Sewing Machine is an indispensable asset in the textile industry, particularly for those specializing in heavy-duty bags. Its capabilities not only enhance production efficiency but also contribute to the quality and reliability of the final product. As the industry continues to evolve, the importance of such specialized machinery will only grow, paving the way for more sustainable and efficient manufacturing practices. By understanding and leveraging the features of this machine, manufacturers can position themselves competitively in the market, ready to meet the demands of an ever-changing landscape.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025