Innovative Leather Bag Manufacturing Equipment for Efficient Production and Superior Quality Craftsmanship

The Craft of Leather Bag Making The Role of Leather Bag Making Machines

The art of leather bag making has captivated artisans and consumers alike for centuries. The combination of durability, elegance, and versatility inherent in leather makes it a coveted material for crafting bags that are not only functional but also stylish. Over time, advancements in technology have introduced leather bag making machines that enhance production efficiency, precision, and quality while preserving the traditional craftsmanship.

Leather bag making is a meticulous process that traditionally relied on the skills of skilled craftsmen who cut, stitch, and assemble the pieces by hand. However, as demand for leather goods has surged, so has the need for more efficient manufacturing solutions. Enter leather bag making machines, which streamline various steps of the production process. These machines range from cutting tools to sewing machines and finishing equipment, all designed to speed up the workflow without compromising on quality.

One of the key advantages of using leather bag making machines is the precision they offer. In handcrafting, slight variations are expected, but in mass production, consistency is crucial. Machines can cut leather into patterns with exact measurements, ensuring that each piece is identical, which is essential for brands that strive to maintain a uniform look in their products. This level of precision not only enhances the aesthetic appeal but also improves the overall durability of the bags.

Another significant benefit of leather bag making machines is their ability to speed up the production process. Where a skilled artisan might take hours to create a single bag, machines can produce multiple pieces in a fraction of the time. This increased efficiency allows businesses to meet growing consumer demands and reduce turnaround times, resulting in higher profitability.

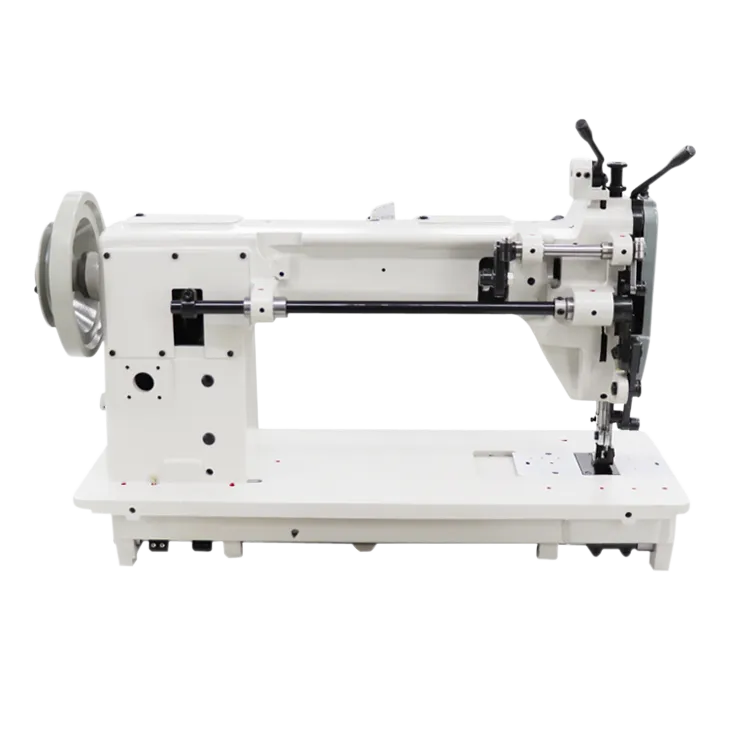

leather bag making machine

Sewing is another crucial aspect of leather bag production. Advanced sewing machines are specifically designed for leather, equipped with robust needles and powerful feeding mechanisms that can handle thick materials without skipping stitches. These machines often come with various attachments, enabling artisans to create intricate designs and ensure strong seams that can withstand daily wear and tear.

Moreover, modern leather bag making machines often incorporate computer numerical control (CNC) technology, which allows for intricate designs to be programmed and executed with remarkable accuracy. This capability opens up new possibilities for customization, allowing brands to offer unique and personalized products to consumers. It also enables small businesses to compete in the larger marketplace by offering niche products without the need for extensive manual labor.

However, the introduction of machines in leather bag making should not overshadow the importance of traditional craftsmanship. The best results come from a harmonious blend of technology and artisan skill. While the machines handle the repetitive and labor-intensive tasks, skilled artisans still apply their expertise in design, quality control, and finishing touches, ensuring each bag meets high standards of quality and aesthetic appeal.

In conclusion, leather bag making machines play an essential role in modern manufacturing, bridging the gap between traditional craftsmanship and modern efficiency. They bring precision, speed, and consistency to the production process, enabling brands to meet the demands of today’s consumers. At the same time, the expertise of artisans remains invaluable, ensuring that the beauty and quality of leather products are upheld. As the industry continues to evolve, one thing remains clear the fusion of technology and craftsmanship will lead the future of leather bag making into new horizons.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025