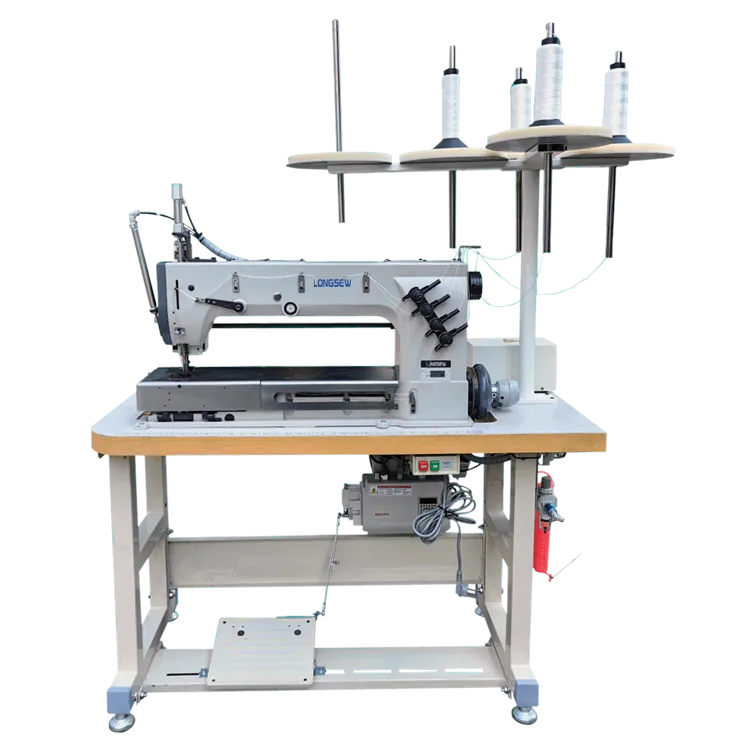

Innovative Dual Function Sewing Machine for Efficient Fabric Handling and Seamless Stitching Experience

The Evolution and Impact of Double Machine Silai Machines

In the ever-evolving world of textile manufacturing, the double machine silai machine stands out as a significant innovation that has transformed the garment industry. This sophisticated piece of equipment, designed to optimize sewing processes, has reshaped the landscape of clothing production, enabling faster and more efficient workflows while enhancing the quality of the final product.

A double machine silai machine typically consists of two sewing heads that operate simultaneously, allowing for the completion of two separate sewing lines at once. This dual functionality not only increases productivity but also reduces labor costs, making it an invaluable asset for manufacturers in Asia, where labor costs can significantly impact overall production expenses. As globalization drives the demand for faster turnaround times in the fashion industry, the use of such machines has become more prevalent.

One of the standout features of the double machine silai machine is its versatility

. Capable of handling a wide variety of fabrics, including cotton, polyester, and blends, it can be used for various applications such as hemming, seaming, and even decorative stitching. This adaptability allows manufacturers to diversify their product offerings without the need for investing in multiple machines, ultimately resulting in cost savings and increased operational efficiency.double machine silai machine

Moreover, the double machine silai machine is engineered with advanced technology that enhances accuracy and precision. With features like automatic thread tension control and programmable stitch patterns, it minimizes human error and ensures a consistent quality in output. The integration of computerized systems into these machines also means that manufacturers can easily adjust settings based on specific garment requirements, improving flexibility and responsiveness to market trends.

The environmental impact of double machine silai machines cannot be overlooked. With the rise of sustainable fashion, manufacturers are becoming increasingly conscious of their ecological footprint. By streamlining production processes and reducing waste through efficient fabric usage, double machines contribute to more sustainable practices within the industry. Additionally, faster production times enable quicker response to changing consumer demands, reducing the likelihood of overproduction and unsold inventory.

Training and skill development are essential for harnessing the full potential of double machine silai machines. As manufacturers adopt this technological advancement, there is an accompanying necessity for workers to acquire new skills related to machine operation and maintenance. This shift emphasizes the importance of investing in workforce development to ensure that employees can proficiently operate these advanced machines while also fostering a culture of innovation within organizations.

In conclusion, the double machine silai machine represents a remarkable advancement in the textile industry, embodying efficiency, versatility, and sustainability. Its ability to streamline production processes while maintaining high-quality standards makes it a vital tool for manufacturers looking to thrive in a competitive market. As technology continues to evolve, it is essential for industry players to stay abreast of these advancements and adapt accordingly, ultimately ensuring a more sustainable and profitable future for the garment industry. The journey of the double machine silai machine is ongoing, with exciting prospects ahead as the industry embraces innovation and modernization.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025